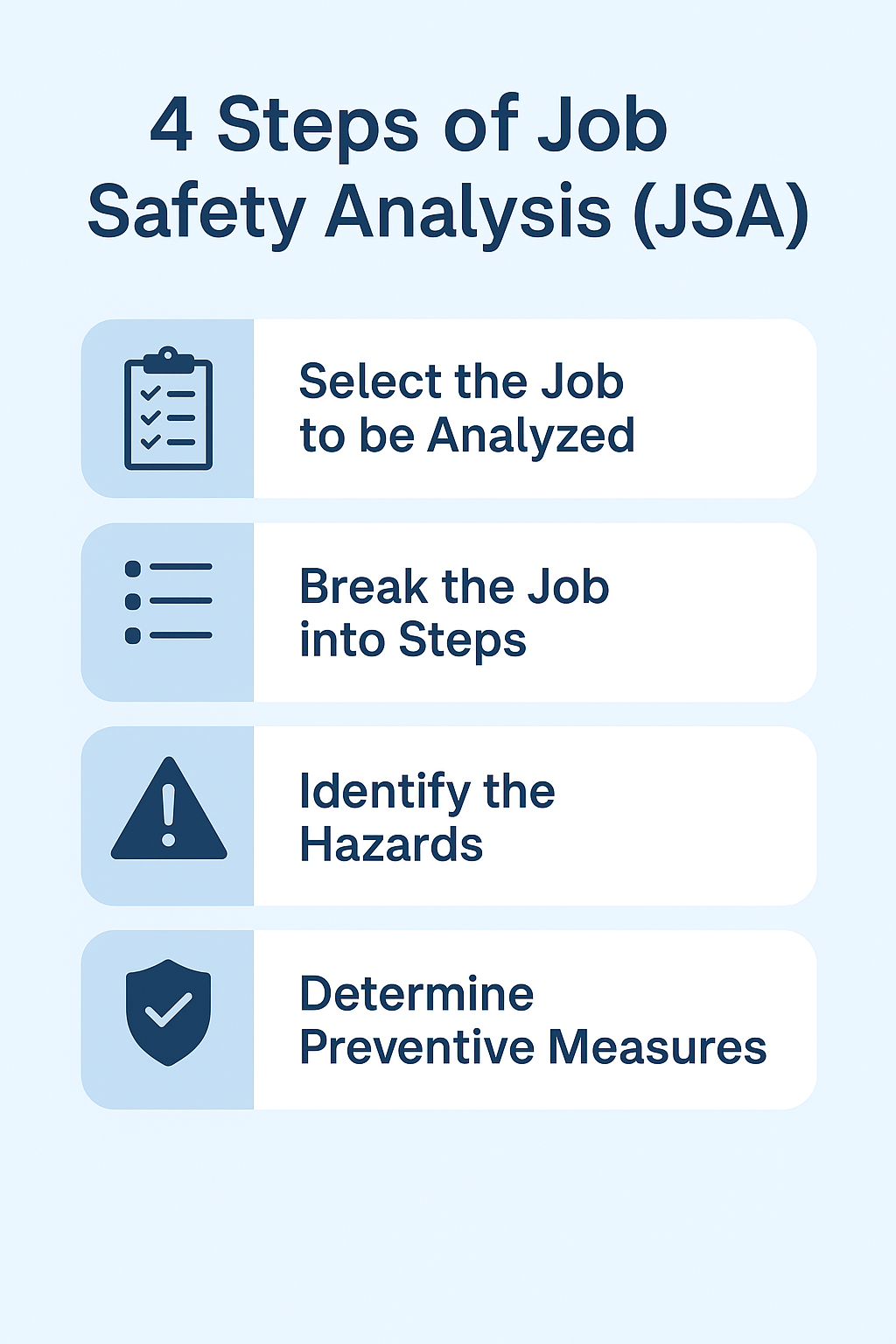

4 Steps of Job Safety Analysis (JSA)

When it comes to workplace safety, guessing is not an option — especially in high-risk environments like construction, manufacturing, or oil and gas. This is where Job Safety Analysis (JSA) becomes a game-changer. JSA is a proactive approach that helps identify and control hazards before they cause harm. By breaking down a job into its individual steps and analyzing each one for potential risks, you can create a safer, more efficient work environment.

But here’s the deal: not everyone understands how to perform a JSA properly. That’s why knowing the four essential steps of JSA — and how to apply them — is so important. In this article, we’ll walk you through each step using a real-world example so you can see exactly how it’s done.

1. Select the Job to be Analyzed

Choose a specific job or task that has a higher risk of injury or has caused incidents in the past. Prioritize:

- Jobs with a history of accidents or near misses

- New or modified tasks

- High-risk operations

2. Break the Job into Steps

Divide the job into a sequence of steps (typically 5–10 steps). Each step should describe a specific action or task the worker performs, such as:

- Picking up materials

- Climbing a ladder

- Operating machinery

3. Identify the Hazards

For each step, identify potential hazards. Ask:

- What can go wrong?

- What could cause injury or damage?

- What unsafe conditions or actions exist?

4. Determine Preventive Measures

Recommend actions to eliminate or reduce the risks. These may include:

- Engineering controls (e.g., machine guards)

- Administrative controls (e.g., training, procedures)

- Personal Protective Equipment (PPE)

4 Steps of Job Safety Analysis (JSA) with Example

Let’s assume the task is: “Using a Portable Grinder” in a workshop.

1. Select the Job to be Analyzed

✔️ What to Do:

Choose a job that has:

- A high injury rate

- Potential for serious consequences

- Infrequent or non-routine activity

- Complex steps

Example:

Task Selected: Using a portable angle grinder to smooth metal edges.

Why this task?

It involves rotating machinery, flying sparks, and sharp objects — all high-risk factors.

2. Break the Job into Steps

✔️ What to Do:

Break the job into simple steps (no more than 10). Each step should describe what is done — not how or why.

Example:

| Step No. | Job Step |

|---|---|

| 1 | Inspect and prepare the grinder |

| 2 | Put on required PPE |

| 3 | Secure the metal piece on the table |

| 4 | Plug in and test the grinder |

| 5 | Start grinding the edges |

| 6 | Power off and store the equipment |

3. Identify the Hazards

✔️ What to Do:

List possible hazards for each job step. Think about:

- Physical hazards (cuts, noise, vibration)

- Environmental (sparks, flammable materials)

- Behavioral (poor posture, distractions)

Example:

| Step | Hazard Identified |

|---|---|

| 1 | Damaged wire or disk may cause shock or flying debris |

| 2 | Missing PPE can lead to cuts, sparks in eyes, or inhalation |

| 3 | Unsecured metal may slip and cause cuts or injury |

| 4 | Grinder may start abruptly causing hand injury |

| 5 | Sparks could ignite flammable material nearby |

| 6 | Improper storage may damage tool or cause trip hazard |

4. Determine Preventive Measures

✔️ What to Do:

Decide how to eliminate or control each hazard using the Hierarchy of Controls:

- Eliminate the hazard

- Substitute safer options

- Use engineering controls

- Apply administrative controls (training, procedures)

- Use PPE (last resort)

Example:

| Step | Hazard Identified | Control Measures |

|---|---|---|

| 1 | Damaged wire or disk | Inspect tools before use; replace faulty parts |

| 2 | Missing PPE | Mandatory use of gloves, face shield, goggles, apron |

| 3 | Unsecured metal piece | Clamp workpiece securely before grinding |

| 4 | Grinder starts abruptly | Test run tool away from body and others |

| 5 | Flying sparks may ignite material | Keep flammables away, use spark guard or fire blanket |

| 6 | Improper storage of grinder | Store grinder in a safe, dry, and marked area |

Final Outcome:

A clear Job Safety Analysis Sheet with:

- Defined steps

- Associated hazards

- Controls in place

This helps workers understand risks and take steps to work safely and efficiently.

Conclusion

Job Safety Analysis isn’t just a paperwork exercise — it’s a life-saving practice. By selecting the right job, breaking it into manageable steps, identifying potential hazards, and putting controls in place, you take a giant step toward protecting lives and improving productivity.

Whether you’re a safety officer, supervisor, or frontline worker, mastering these four steps can help you spot danger before it strikes. Remember, a few minutes spent doing a proper JSA can prevent days — or even months — of injury, downtime, or tragedy. Stay smart, stay safe!

Risk Management 101: Conducting Effective Risk Assessments

Risk Matrix vs Risk Assessment: What’s the Difference?

How to Create an Effective Risk Matrix for Your Workplace

What is a Risk Matrix? A Beginner’s Guide

Types of Risk Matrix: 3×3, 4×4 and 5×5

FAQs

1. What is the main purpose of a Job Safety Analysis (JSA)?

The main goal of a JSA is to identify hazards before they happen and implement measures to eliminate or control those risks. It promotes safer work practices and helps prevent injuries.

2. Who should be involved in conducting a JSA?

Ideally, a team including the supervisor, safety officer, and workers familiar with the task should be involved. Workers often have firsthand knowledge of the job and potential hazards.

3. How often should a JSA be updated?

A JSA should be reviewed and updated:

- When a job changes

- After an incident or near miss

- Periodically as part of routine safety reviews

4. Is a JSA required by law?

While JSA is not always legally mandated, many health and safety regulations (like OSHA in the U.S.) recommend or require hazard analysis for high-risk jobs. Employers are responsible for providing a safe work environment.

5. What’s the difference between JSA and risk assessment?

A JSA focuses on task-specific hazard identification and control, while a risk assessment can cover a broader range of activities, processes, or equipment. JSA is more detailed for a specific job role or task.