Ergonomic Hazards in Office and Construction Work

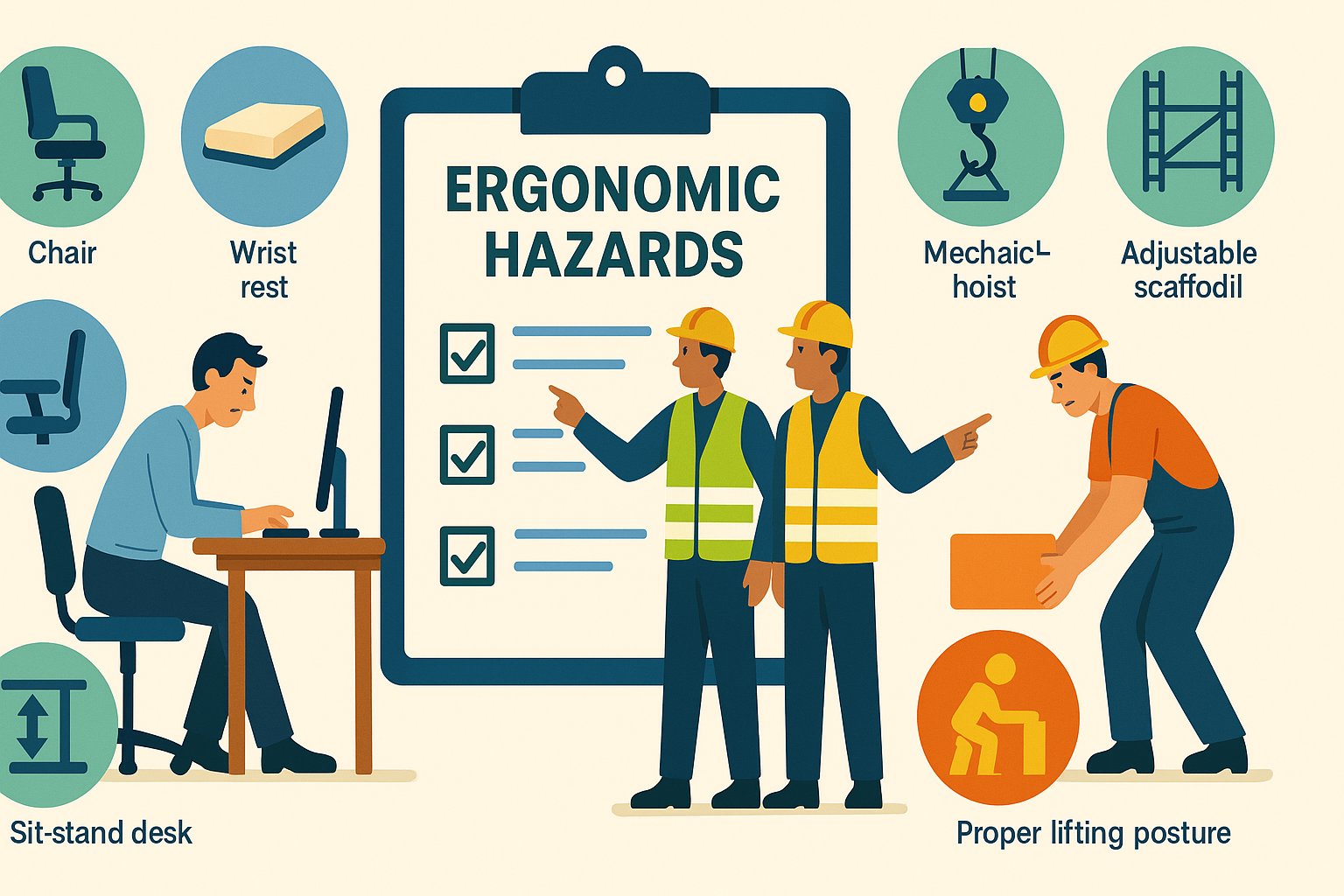

Ergonomic hazards are among the most overlooked workplace risks, yet they contribute significantly to musculoskeletal disorders (MSDs), fatigue, and reduced productivity. While office workers are prone to hazards from poor workstation setup, construction workers face ergonomic risks from heavy lifting, awkward postures, and repetitive tasks. This article explains ergonomic hazards, how to identify them in both office and construction settings, and how to control them effectively.

1. What Are Ergonomic Hazards?

Ergonomic hazards arise when the job demands exceed the worker’s physical capacity or involve awkward postures, repetitive motions, or poorly designed tools. They can cause acute injuries or long-term chronic conditions.

Examples:

- Poor seating or workstation layout.

- Repetitive data entry without breaks.

- Manual handling of heavy loads.

- Working in awkward positions such as bending or kneeling for long periods.

2. Ergonomic Hazards in Office Work

2.1 Common Risks

- Poor Posture: Chairs without lumbar support, low desks, or monitors placed too high/low.

- Repetitive Movements: Typing, mouse use, or data entry.

- Static Postures: Sitting for prolonged periods without breaks.

- Poor Lighting/Glare: Eye strain and awkward head positions.

2.2 Health Effects

- Back and neck pain.

- Carpal tunnel syndrome.

- Eye strain and headaches.

- Reduced productivity and absenteeism.

2.3 Identification

- Conduct ergonomic assessments of workstations.

- Survey employees about discomfort or pain.

- Use checklists to evaluate posture, workstation design, and lighting.

2.4 Control Measures

- Engineering Controls: Adjustable chairs, sit-stand desks, ergonomic keyboards.

- Administrative Controls: Break schedules, job rotation, training on proper posture.

- PPE: Anti-glare screen filters, wrist supports.

3. Ergonomic Hazards in Construction Work

3.1 Common Risks

- Manual Material Handling: Lifting, carrying, pushing, pulling heavy loads.

- Awkward Postures: Bending, kneeling, working overhead.

- Repetitive Tasks: Bricklaying, rebar tying, or jackhammer use.

- Vibration: Tools causing hand-arm vibration.

3.2 Health Effects

- Musculoskeletal disorders (MSDs).

- Sprains and strains.

- Chronic back injuries.

- Reduced stamina and increased fatigue.

3.3 Identification

- Observe workers during tasks for awkward postures.

- Measure load weights and frequency of lifting.

- Collect injury and absenteeism data to identify patterns.

3.4 Control Measures

- Engineering Controls: Mechanical lifting aids, adjustable scaffolding, power tools with ergonomic handles.

- Administrative Controls: Rotate heavy tasks, plan material placement to reduce lifting distances, provide training in proper lifting techniques.

- PPE: Knee pads, supportive footwear, anti-vibration gloves.

4. Implementing Ergonomic Programs

- Conduct baseline ergonomic risk assessments for all tasks.

- Involve workers in identifying problems and testing solutions.

- Provide training on posture, lifting techniques, and microbreaks.

- Monitor the effectiveness of controls and adjust as needed.

For detailed guidelines, visit OSHA’s Ergonomics page.

Exam-Oriented Questions with Detailed Answers

Short Answer Questions

Q1. Define ergonomic hazard and give two examples.

Answer: An ergonomic hazard is any workplace condition where job demands and work environment exceed a worker’s physical capacity. Examples: Poor seating in offices and heavy lifting in construction.

Q2. List three common ergonomic risks in office work.

Answer: Poor posture due to non-adjustable chairs, repetitive typing without breaks, and glare from monitors causing awkward head positions.

Q3. Name two engineering controls for ergonomic hazards in construction work.

Answer: Mechanical lifting aids and adjustable scaffolding.

Long Answer Questions

Q1. Describe the health effects of ergonomic hazards in office settings.

Answer: Poor workstation design and prolonged sitting can cause musculoskeletal disorders such as back and neck pain, carpal tunnel syndrome from repetitive typing, and eye strain from improper lighting. These lead to reduced productivity, absenteeism, and chronic discomfort. Controls include ergonomic furniture, microbreaks, and training.

Q2. Discuss how ergonomic hazards can be controlled in construction work.

Answer: Apply the hierarchy of controls: Use mechanical lifting devices (engineering), plan material layout to reduce manual handling (administrative), rotate heavy tasks, and provide PPE like knee pads and anti-vibration gloves. Training workers on proper lifting techniques also reduces injury risks.

Q3. Explain the importance of ergonomic assessments and how they are conducted.

Answer: Ergonomic assessments identify mismatches between job demands and worker capacity. They involve observing tasks, measuring loads, interviewing workers about discomfort, and using checklists. This data informs control measures like redesigning workstations, implementing rotation, or providing supportive equipment.

Scenario-Based Questions

Q1. An office employee complains of chronic wrist pain from typing. How should this be addressed?

Answer: Conduct an ergonomic assessment of the workstation, provide an ergonomic keyboard and wrist rest, adjust chair and desk heights, and schedule microbreaks. Offer training on proper typing posture.

Q2. Construction workers are frequently bending to lift bricks. What controls would you implement?

Answer: Provide adjustable brick stands to raise materials to waist height (engineering), rotate tasks among workers (administrative), train on proper lifting techniques, and supply supportive footwear.

Q3. A worker reports back pain from operating a jackhammer daily. What steps should be taken?

Answer: Introduce anti-vibration handles and mechanical aids, limit daily exposure time, rotate tasks, provide anti-vibration gloves and back support, and review the worker’s posture and technique.

Frequently Asked Questions (FAQs)

1. What are ergonomic hazards?

Answer: Workplace conditions such as poor posture, repetitive motions, or manual handling that can cause musculoskeletal disorders.

2. How can office workers reduce ergonomic risks?

Answer: Use adjustable chairs and desks, position monitors at eye level, take regular breaks, and practice good posture.

3. Why are ergonomic hazards significant in construction?

Answer: Because heavy lifting, awkward postures, and repetitive tasks increase the risk of musculoskeletal injuries and chronic pain.

4. Are anti-vibration gloves sufficient to prevent vibration injuries?

Answer: They help reduce the impact but should be combined with engineering and administrative controls such as low-vibration tools and limited exposure time.

5. How often should ergonomic assessments be conducted?

Answer: At least annually or whenever tasks, equipment, or workspaces change.

6. Can ergonomic hazards be eliminated completely?

Answer: Some can be eliminated (e.g., automating heavy lifts), but many must be managed through a combination of controls and good practices.

5. Conclusion

Ergonomic hazards, whether in offices or on construction sites, can significantly impact worker health and productivity. Identifying these hazards, assessing the risks, and applying controls according to the hierarchy — from engineering solutions to training and PPE — reduces injuries and improves overall performance.

Physical Hazards at Work (Noise, Vibration, Heat, Radiation): Identification & Control

Hazard Identification, Risk Assessment, and Risk Control (HIRARC)

The Hierarchy of Controls Explained: How to Manage Hazards Effectively

Difference Between Hazard and Risk: A Practical Guide for Safety Professionals