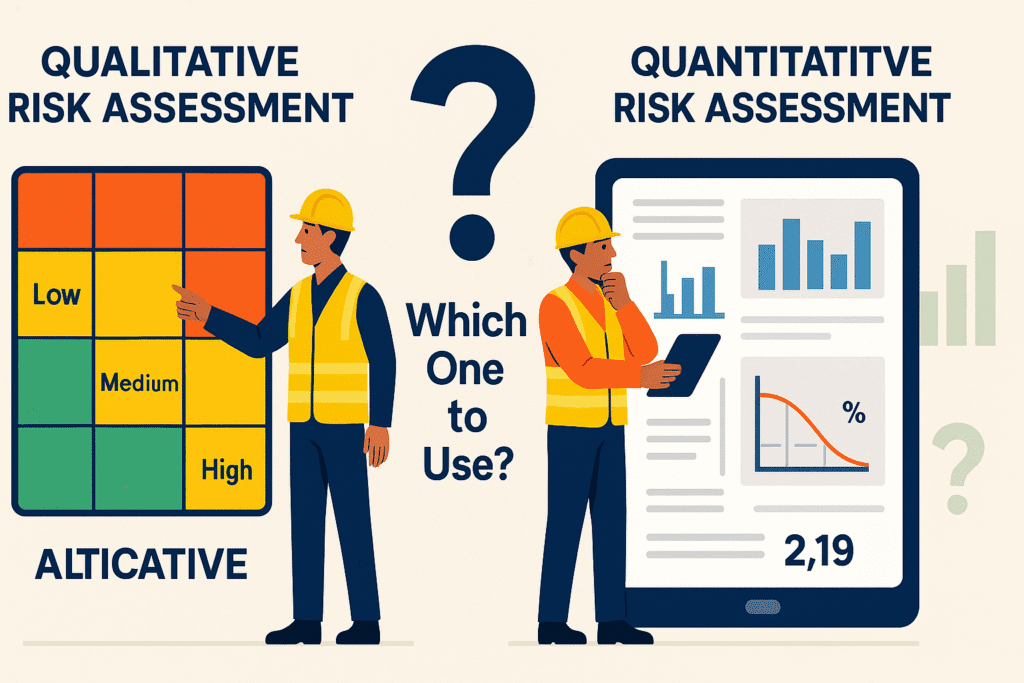

Quantitative vs Qualitative Risk Assessment: Which One to Use?

Risk assessment is at the heart of occupational health and safety. But not all risk assessments are the same. The two most common approaches are qualitative and quantitative risk assessment. Choosing the right one depends on the type of hazards, available data, and organisational needs. This guide explains each method, compares them, and helps you decide which one to use — complete with exam-oriented questions and answers.

1. What is Risk Assessment?

Risk assessment is a systematic process of identifying hazards, evaluating the likelihood and severity of harm, and determining control measures. It forms the backbone of safety management systems such as ISO 45001 and OSHA programs.

2. Qualitative Risk Assessment

2.1 Definition

A qualitative risk assessment uses descriptive terms (like low, medium, high) to rank risks. It relies on professional judgement and experience rather than numerical data.

2.2 Key Features

- Uses risk matrices or colour-coded charts.

- Relies on expert judgement and historical data.

- Suitable when detailed data is lacking or time is limited.

2.3 Example

Evaluating slip hazards on a shop floor:

- Likelihood: “Possible”

- Severity: “Major injury”

- Risk Level: “High” (based on matrix)

2.4 Advantages

- Quick and easy to implement.

- Good for initial screening of hazards.

- Involves workers and promotes discussion.

2.5 Limitations

- Subjective; results may vary between assessors.

- Harder to justify for regulatory or high-stakes decisions.

- Doesn’t calculate actual risk values.

3. Quantitative Risk Assessment

3.1 Definition

A quantitative risk assessment (QRA) assigns numerical values to the likelihood and severity of hazards. It uses statistical data, modelling, or calculations to produce risk numbers or probabilities.

3.2 Key Features

- Uses formulas like Risk = Likelihood × Consequence.

- Requires reliable data and analytical tools.

- Provides numerical risk scores (e.g., 1 in 10,000 chance per year).

3.3 Example

Analysing explosion risk in a chemical plant:

- Likelihood: 1×10⁻⁴ per year.

- Consequence: Fatalities and $X million loss.

- Individual Risk of Fatality: 1×10⁻⁵ per year.

3.4 Advantages

- More objective and reproducible.

- Supports cost-benefit analysis and prioritisation.

- Better suited for complex or high-risk operations.

3.5 Limitations

- Data-intensive and time-consuming.

- Requires skilled analysts and software.

- May give a false sense of precision if data is poor.

4. Key Differences Between Qualitative and Quantitative

| Aspect | Qualitative Risk Assessment | Quantitative Risk Assessment |

|---|---|---|

| Data Requirement | Minimal; descriptive | Extensive; numerical |

| Speed | Quick | Time-consuming |

| Output | Risk levels (Low/Medium/High) | Probabilities, numerical risk scores |

| Best For | Initial screening, low-risk tasks | High-risk, complex processes |

| Example | Risk matrix for slips and trips | Explosion frequency analysis in chemical plant |

5. Which One Should You Use?

5.1 Use Qualitative When:

- You need a rapid or preliminary assessment.

- Detailed data is not available.

- The hazards are well-known and low-risk.

5.2 Use Quantitative When:

- The operation is high-risk or high-consequence.

- Regulators or insurers require detailed analysis.

- You have reliable data and expertise to support calculations.

Hybrid Approach:

Many organisations start with a qualitative assessment to screen hazards, then perform quantitative analysis on high-risk areas.

6. Integrating Both Methods

- Begin with a qualitative risk matrix for all tasks.

- Flag high-risk areas for quantitative study.

- Use QRA results to inform control measures, emergency planning, and cost-benefit decisions.

For official guidance, see OSHA’s page.

Exam-Oriented Questions with Detailed Answers

Short Answer Questions

Q1. Define qualitative risk assessment.

Answer: It’s a risk assessment method that uses descriptive ratings like low, medium, or high to rank risks based on professional judgement rather than numerical data.

Q2. Define quantitative risk assessment.

Answer: It’s a method that uses numerical data and statistical modelling to calculate the likelihood and severity of hazards, producing risk scores or probabilities.

Q3. When should a hybrid approach be used?

Answer: When an organisation needs quick screening of all hazards but also detailed analysis for high-risk operations.

Long Answer Questions

Q1. Compare the advantages and limitations of qualitative vs. quantitative risk assessment.

Answer: Qualitative risk assessment is quick, easy, and promotes discussion but is subjective and less precise. Quantitative risk assessment is objective, data-driven, and supports high-stakes decisions but is resource-intensive and may give a false sense of accuracy if data is poor. Choosing the right method depends on hazard complexity, available data, and regulatory needs.

Q2. Describe a scenario where quantitative risk assessment would be more appropriate than qualitative.

Answer: In a chemical plant storing large volumes of hazardous substances, quantitative analysis is essential to model explosion probabilities, estimate potential fatalities, and plan emergency response. A qualitative “high risk” label would be insufficient for regulators or insurers.

Q3. Explain how combining qualitative and quantitative methods can improve risk management.

Answer: A combined approach allows organisations to efficiently screen all hazards (qualitative) and then focus resources on detailed analysis of critical risks (quantitative). This yields both breadth and depth, improving decision-making and resource allocation.

Scenario-Based Questions

Q1. A small office wants to assess slip and trip hazards. Which method should it use and why?

Answer: Qualitative risk assessment because the hazards are low-risk, well-known, and data for quantitative analysis is unnecessary.

Q2. An oil refinery needs to evaluate the risk of catastrophic explosions. Which method is best and why?

Answer: Quantitative risk assessment because the consequences are severe, data is available, and detailed modelling is required for regulatory compliance.

Q3. A construction company wants to prioritise safety investments. How should it approach risk assessment?

Answer: Use a qualitative assessment to identify high-risk tasks across projects, then conduct quantitative analysis on the most critical ones to justify investments.

Frequently Asked Questions (FAQs)

1. What is the main difference between qualitative and quantitative risk assessment?

Answer: Qualitative uses descriptive ratings (low, medium, high), while quantitative assigns numerical probabilities and consequence values.

2. Which method is faster?

Answer: Qualitative risk assessment is faster and less resource-intensive.

3. Which method is more accurate?

Answer: Quantitative risk assessment can be more accurate if based on reliable data and expertise.

4. Can both methods be used together?

Answer: Yes. Many organisations use a hybrid approach — qualitative for screening and quantitative for high-risk areas.

5. Is quantitative risk assessment required by law?

Answer: It’s not always mandatory, but regulators or insurers may require it for high-risk industries like chemical processing or nuclear power.

6. Do you need special software for quantitative risk assessment?

Answer: Often yes. Software helps model probabilities, consequences, and produce risk curves, especially for complex systems.

7. Conclusion

Choosing between quantitative and qualitative risk assessment depends on the context. Qualitative methods are best for quick, broad screening of hazards; quantitative methods are essential for high-stakes or complex risks where data supports modelling. Many organisations benefit from a hybrid approach — starting qualitative, then moving to quantitative for critical hazards.

Psychosocial Hazards: Stress, Fatigue, and Workplace Violence

Ergonomic Hazards in Office and Construction Work

Biological Hazards in Healthcare and Laboratory Environments

Chemical Hazards and Exposure Risks in Industrial Settings

Physical Hazards at Work (Noise, Vibration, Heat, Radiation): Identification & Control