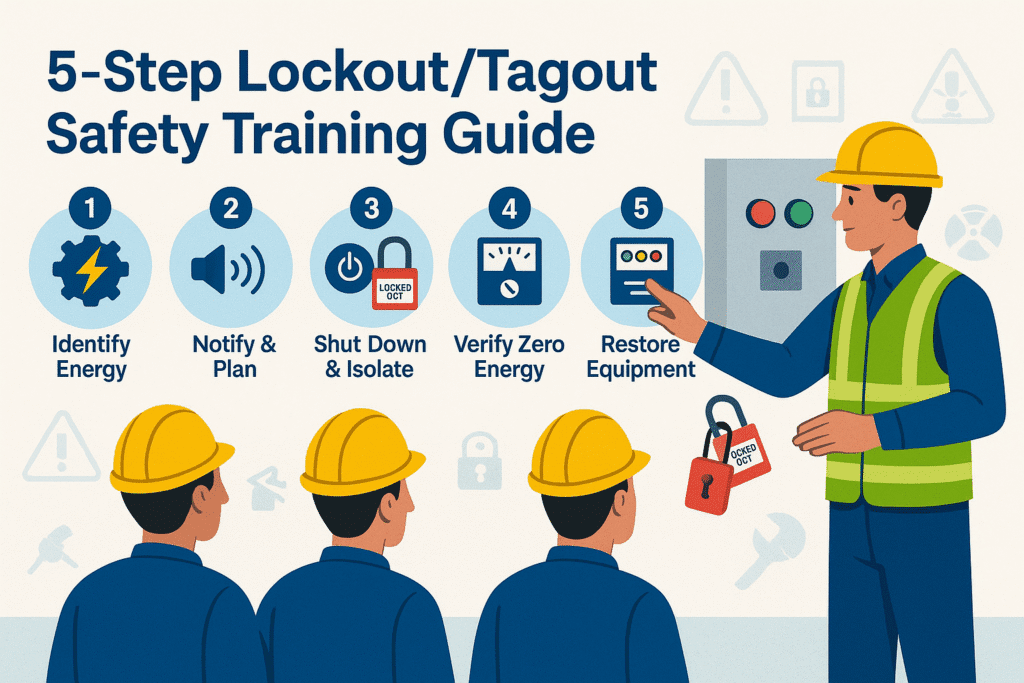

5-Step Lockout Tagout Safety Training Guide for Maintenance Teams

Servicing and maintaining machines often exposes workers to hazardous energy sources like electricity, steam, hydraulics, or compressed air. Without proper procedures, accidental startups can cause severe injuries or fatalities. Lockout Tagout (LOTO) is a critical safety practice designed to control hazardous energy during maintenance tasks.

This article presents a 5-Step Lockout Tagout Safety Training Guide to help maintenance teams implement LOTO correctly and protect themselves from harm.

Why Lockout/Tagout Safety Training Matters

- Hazardous Energy Control: OSHA estimates proper LOTO procedures prevent 120 fatalities and 50,000 injuries annually.

- Legal Compliance: Regulations worldwide require controlling hazardous energy during servicing and maintenance.

- Consistency: A structured approach ensures every worker follows the same safe steps.

- Safety Culture: Training shows employees their well-being is a priority.

External link tip: OSHA Control of Hazardous Energy (Lockout/Tagout)

Step 1: Identify and Evaluate Hazardous Energy Sources

Before applying locks or tags, employees must know what they’re isolating. This step involves:

- Energy Source Mapping: Identify all energy types — electrical, mechanical, hydraulic, pneumatic, chemical, or thermal.

- Equipment Assessment: Review machine manuals, schematics, and energy control procedures.

- Multiple Energy Points: Some machines have more than one source; all must be addressed.

Example: A packaging machine may have electrical power, compressed air, and hydraulic pressure. Each source requires isolation.

Training Tip: Use visual aids like energy source diagrams to help teams understand where hazards exist.

Step 2: Notify Affected Employees and Plan the Shutdown

Communication prevents surprises. Before shutting down equipment:

- Inform Everyone: Notify operators, contractors, and supervisors that maintenance will occur.

- Plan the Sequence: Decide who will perform the lockout, which devices to use, and in what order.

- Check for Co-Workers: Ensure no one is in danger when starting the process.

Example: A maintenance lead announces over the PA system and places “Machine Under Maintenance” signs before locking out.

Training Tip: Practice mock notifications as part of LOTO training.

Step 3: Shut Down and Isolate the Equipment

This is the heart of LOTO:

- Turn Off Controls: Stop the machine using its normal stopping procedure.

- Isolate Energy Sources: Disconnect or block power sources (switch off breakers, close valves, release stored energy).

- Apply Lockout Devices: Place locks on energy-isolating devices. Only the person doing the maintenance should hold the key.

- Attach Tags: Clearly state “Do Not Operate” with name, department, and date.

Example: A technician shuts off the main disconnect, closes the air supply valve, and locks both with individual padlocks.

Training Tip: Demonstrate correct lock placement using actual equipment during training.

Step 4: Verify Zero Energy State

Never assume the equipment is safe just because it’s locked out. Always verify:

- Test Equipment: Press start buttons or test controls to ensure no movement.

- Use Meters: For electrical circuits, use a properly rated voltage tester to confirm zero energy.

- Release Stored Energy: Bleed off residual pressure, drain liquids, discharge capacitors.

Example: After locking out a pump, a worker opens a bleed valve to release trapped pressure before beginning maintenance.

Training Tip: Teach workers to always “try out” after lockout before beginning work.

Step 5: Perform Maintenance and Restore Equipment Safely

When maintenance is complete:

- Inspect Work Area: Ensure all tools and personnel are clear.

- Remove Lockout Devices: Only the person who applied the lock or tag may remove it.

- Notify Affected Employees: Announce the machine is ready for operation.

- Return to Service Gradually: Start up equipment and check for proper operation.

Example: After repairs, a technician removes his lock, informs the supervisor, and observes a test run before releasing the equipment to production.

Training Tip: Use checklists for restoring equipment to avoid missing steps.

Implementing the 5-Step LOTO Training Guide

To make training effective:

- Use Real Equipment: Practice on actual machines where possible.

- Hands-On Demonstrations: Show, don’t just tell, how to lockout and tagout.

- Assess Competency: Quizzes and supervised practice confirm understanding.

- Refresh Annually: Provide refresher training or when equipment or procedures change.

- Document Everything: Keep training records for compliance audits.

Benefits of 5-Step Lockout/Tagout Safety Training

- Fewer Injuries: Prevents accidental energization during maintenance.

- Compliance: Meets OSHA/NEBOSH/ISO hazardous energy control standards.

- Confidence: Workers know exactly what to do in each step.

- Consistency: Standardized procedures reduce confusion.

Key Takeaways

Lockout/Tagout is not just a procedure — it’s a life-saving practice. By teaching maintenance teams this 5-Step Safety Training Guide, you ensure hazardous energy is controlled every time, reducing accidents and improving workplace safety.

Suggested Internal & External Links

- External: OSHA Lockout/Tagout Standard

- Internal: 10 Powerful Electrical Safety Training Tips to Prevent Shocks

- 12 Ultimate Fire Prevention Training Tips for Workers

- 6 Proven Emergency Preparedness Training Drills for Any Industry

- 8 Critical Fire Safety Training Lessons to Save Lives

- 10 Must-Know Workplace Safety Training Topics for Every Employee

Frequently Asked Questions

1. What is lockout/tagout (LOTO) training?

It’s a structured program teaching workers how to control hazardous energy during maintenance and servicing to prevent accidental startups.

2. Who needs lockout/tagout safety training?

All maintenance staff, contractors, and anyone who may service or maintain equipment with hazardous energy sources.

3. How often should LOTO training be refreshed?

At least annually, or whenever new equipment or processes are introduced that change energy control procedures.

4. What are the five steps of lockout/tagout training?

Identify hazardous energy, notify and plan shutdown, shut down and isolate equipment, verify zero energy, and restore equipment safely.

5. Can multiple workers apply their own locks?

Yes. Each worker performing maintenance should apply their own lock to ensure personal protection.