Shoring, Sloping and Benching: Protective Systems Explained

Excavation work is one of the most hazardous operations in the construction industry. Whether digging a trench for utilities, cutting into earth for foundations, or preparing basement structures, workers are exposed to risks such as cave-ins, falling loads, hazardous atmospheres, and equipment interactions. Among these hazards, cave-ins are the most deadly, accounting for the majority of excavation-related fatalities worldwide.

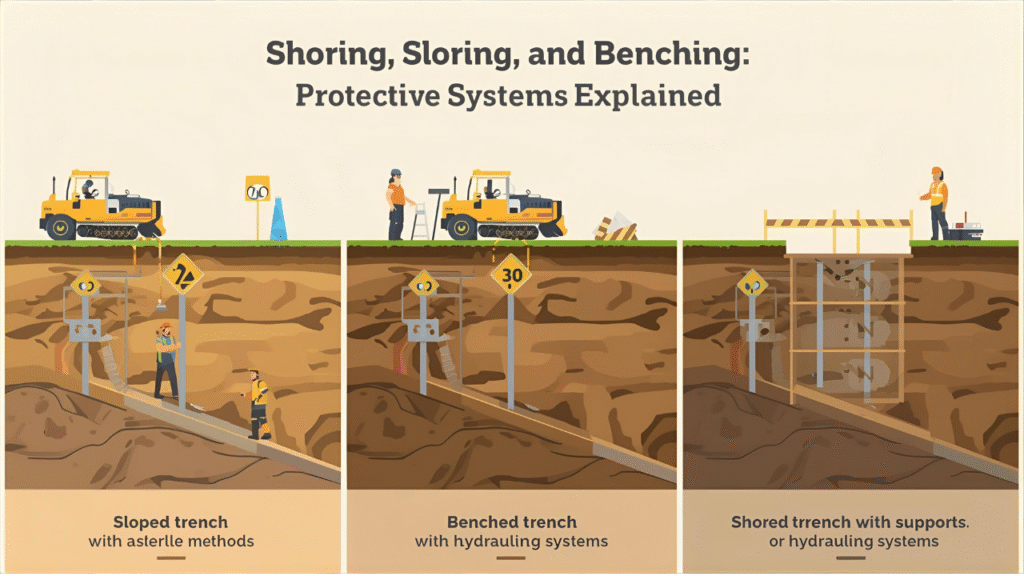

To mitigate these risks, engineering control methods known as protective systems are used. These include:

- Sloping — modifying the natural angle of the trench

- Benching — cutting stepped levels into soil walls

- Shoring — supporting trench walls with structural systems

- Shielding — protecting workers using trench boxes*

(*Shielding is not the main topic, but will be referenced for clarity.)

This comprehensive guide explains each method in depth, when and why it should be used, how soil type affects selection, compliance requirements, and best practices for implementation.

Understanding Why Protective Systems Are Necessary

Excavation walls fail for multiple reasons including soil weight, moisture presence, underground water pressure, vibration from nearby machinery, surface loads, and natural instability.

Weight and Pressure Forces

Soil exerts lateral pressure on trench walls. The deeper the trench, the greater the pressure.

Water Saturation

Moisture increases soil weight and reduces cohesion, making collapse more likely.

Vibrations

Nearby traffic, construction activities, and even foot movement can trigger collapse.

Time Factor

The risk of cave-ins increases over time as excavations are open longer.

Because collapses happen instantly and without warning, protective systems provide structural security and life-saving reinforcement.

Sloping: Allowing Soil to Rest at Its Natural Angle

Sloping is a method of cutting back trench walls so that soil rests at an angle, where gravitational forces are naturally balanced.

How Sloping Works

Instead of leaving vertical trench walls, the sides are angled away from the excavation. This reduces lateral earth pressure and minimizes collapse risk.

Slope Ratios by Soil Type

Soil classifications per OSHA:

| Soil Type | Minimum Slope Ratio | Description |

|---|---|---|

| Stable Rock | Vertical (90°) | Self-supporting rock |

| Type A Soil | ¾ : 1 | Clay: very cohesive |

| Type B Soil | 1 : 1 | Medium stability |

| Type C Soil | 1½ : 1 | Loose sand or gravel |

Example:

For every 1 m depth in Type C soil, excavation must extend 1.5 m horizontally from the base.

Advantages of Sloping

- Simple and effective

- No equipment required

- Uses natural soil strength

Limitations of Sloping

- Needs large open working areas

- Not suitable in crowded urban environments

- Not ideal when space must be minimized

Benching: Creating Steps for Stability

Benching is the method of cutting soil walls into horizontal steps to reduce pressure.

How Benching Works

Instead of one continuous slope, soil walls are carved into multiple benches or layers.

Types of Benching

Simple Benching

One or more single-level steps.

Multiple Benching

Series of smaller benches stacked vertically.

Where Benching Works Best

- In cohesive soils like clay (Type A and B)

- In moderately deep excavations

- When limited horizontal space compared to sloping

Restrictions

- Not allowed in Type C soil

- Water seepage or heavy rainfall may weaken benches

- Workers must be aware of the bench levels when moving inside trenches

Advantages of Benching

- Provides additional workspace and footing

- Reduces soil pressure effectively

- Safer descent and movement inside trenches

Shoring: Mechanical Reinforcement of Trench Walls

Shoring is an engineered system that physically supports trench walls using mechanical or structural elements.

How Shoring Works

Support members transfer lateral soil pressure into the support system, preventing collapse.

The most common systems:

Hydraulic Shoring

- Uses hydraulic pistons and aluminum rails

- Quick installation

- Adjustable to trench width

- Commonly used in Type C soil

Timber Shoring

- Traditional wood-based supports

- Suitable for custom-sized excavations

- Used where hydraulic systems are impractical

Aluminum Hydraulic Shoring

- Lightweight

- Corrosion-resistant

- Easily transported and adjusted

- OSHA-preferred due to reliability

Pneumatic Shoring

- Air-pressurized support systems

- Similar to hydraulic, but air-powered

Screw Jacks

- Mechanically adjusted supports

- Used in lighter duty applications

Advantages of Shoring

- Allows trenching in tight spaces

- Suitable for deep or narrow excavations

- Provides confidence and predictable safety

Limitations of Shoring

- Requires setup time

- Requires trained workers

- Can be costly and equipment dependent

Shielding (Trench Boxes) for Worker Protection

While not a true preventative measure for collapse, trench boxes provide a protection zone.

How Shielding Works

Workers enter the trench box — an armored compartment — inside the trench. If a collapse occurs, the box shields the worker.

Where Used

- High-risk excavations

- Deep trenches

- Emergency repair works

- Unstable soil conditions

Important Note

Shielding does not prevent cave-in — it only protects workers from being buried.

Choosing the Right Protective System

Key Factors in Selection

- Soil classification (A, B, or C)

- Depth of excavation

- Moisture and groundwater presence

- Adjacent load pressure (e.g., parked equipment)

- Site congestion and space availability

- Length and duration of excavation

- Weather conditions (dry vs wet soil)

- Presence of utilities or vibration sources nearby

General Decision Guidance

- Where space allows → sloping

- Where moderate space allows → benching

- Where space is restricted → shoring

- Where collapse risk is high → shoring or shielding

How Soil Behavior Influences Protective Systems

Soil stability is primarily influenced by its cohesiveness.

Type A Soil (Clay)

- Very cohesive

- Holds shape well

- Ideal for benching and sloping

Type B Soil

- Less cohesive

- Greater collapse risk than Type A

- Shoring often recommended

Type C Soil

- Loose and crumbly

- Most dangerous type

- Vertical walls NOT permitted

- Best protected by shoring and shielding

Inspection Requirements and Monitoring

Excavations must be inspected at least once daily and:

- After rain

- After thawing/freezing

- After heavy vibration

- When soil changes are observed

Who Performs Inspections?

A competent person — as defined by OSHA — someone capable of identifying hazards and authorized to take corrective action.

Inspection Checklist

- Wall integrity

- Soil moisture conditions

- Condition of protective systems

- Proper placement of spoil piles

- Safe access and egress

- Atmospheric conditions (if required)

- Worker positioning and traffic control

Common Excavation Failures and Warning Signs

Visible Warning Signs

- Cracks in trench walls

- Falling soil fragments

- Bulging or sloping walls

- Water seepage

- Ground movement or settlement

Workers must be trained to recognize and react to warning signs immediately.

Safety Best Practices for Excavation Work

Positioning and Access

- Ladders every 25 feet

- No jumping into trenches

- Stable access points required

Spoil Pile Management

Spoil piles must be kept minimum 2 feet from trench edge to reduce added soil pressure.

Load Restrictions

Avoid:

- Machinery parked near trench

- Materials stacked near edges

- Heavy vibrations by compaction equipment

Training Requirements

Workers must be trained on:

- Soil recognition

- Protective systems operation

- Emergency evacuation

- Communication protocols

- Recognition of collapse risks

Supervisors must reinforce and document training.

Regulatory Requirements and Standards

Regulatory frameworks include:

- OSHA 1926 Subpart P

- ISO excavation safety standards

- Local regulatory codes

- Geotechnical engineering standards

Compliance is legally required in most jurisdictions.

Conclusion

Shoring, sloping, and benching are not optional precautions — they are essential engineering controls that save lives. By selecting a protective system based on soil type, depth, environmental conditions, and workspace constraints, excavation safety becomes predictable and manageable. Every worker entering a trench must be protected by an approved system—because excavation safety is built on prevention, preparation, and respect for soil behavior.

For checklist and templates visit The HSE Tools.

Soil Classification and Testing for Excavation Safety

Excavation Hazards and Their Control Measures

What Is Excavation Work? Definition, Types, and Safety Controls