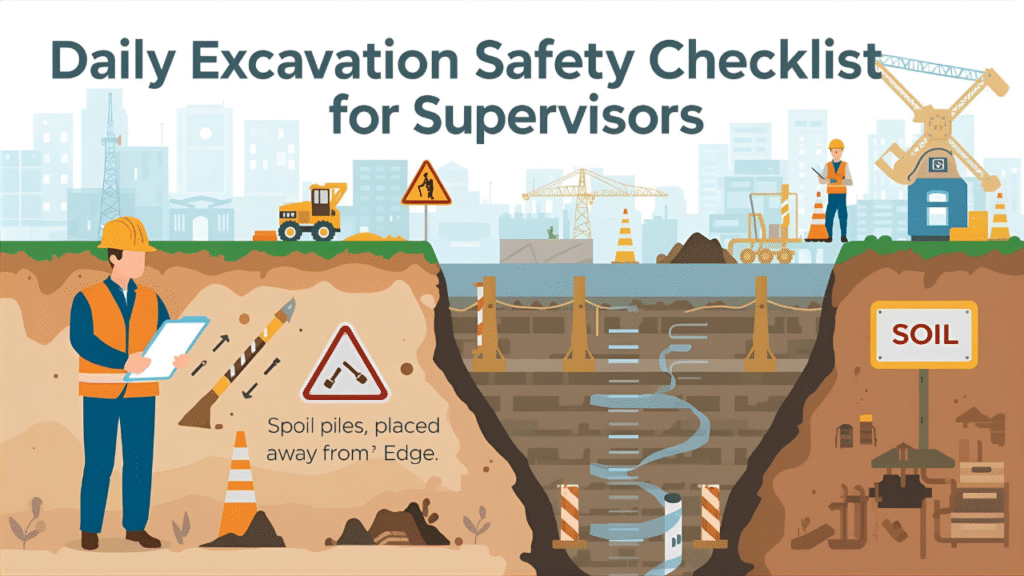

Daily Excavation Safety Checklist for Supervisors

Every excavation site changes day by day — and sometimes minute by minute. Rainfall, vibration, soil movement, heavy loads, and underground conditions can transform a safe trench into a deadly trap. For this reason, excavation supervisors must conduct a structured daily inspection, ensuring protective systems are intact and workers are safe before entry.

This comprehensive checklist serves as a practical, actionable guide — designed specifically for supervisors conducting daily safety verifications according to OSHA, HSE, and industry best practices.

Supervisor’s Daily Excavation Safety Checklist

Below is the full structured checklist that must be reviewed before workers enter the trench.

1. Permit and Documentation

Items to Verify

- Valid Permit to Work issued for the day

- Risk assessment and method statement available

- Soil classification documentation

- Historical inspection records

- Required signatures completed

2. Competent Person Confirmation

Items to Verify

- Designated competent person present

- Has authority to stop work

- Has trench safety training

- Performs inspection personally

3. Soil and Environmental Conditions

Items to Verify

- Soil stability checked

- No water seepage

- No settlement cracks

- No loose debris along trench walls

- Condition changes after rain or weather events

4. Weather Impact Assessment

Items to Verify

- Rain forecast reviewed

- Wind loads considered for loose materials

- Temperature effects on soil moisture checked

- No pooling water in trench

5. Protective Systems Selection

Items to Verify

- Appropriate system in use:

- Sloping

- Benching

- Shoring

- Shielding (Trench Box)

- System meets soil class requirements

- Installed correctly

- Inspected for damage or misalignment

- Not altered by unauthorized persons

6. Spoil Pile Placement

Items to Verify

- Spoil piles ≥ 2 ft from trench edge

- Materials stored safely

- No heavy equipment parked near trench

- No loose rock or debris near edge

7. Utilities and Underground Services

Items to Verify

- Utility maps reviewed

- Marking for gas lines, electrical lines, etc.

- Cable locators used

- No digging above suspected utilities

- Hand digging performed near utilities

8. Access and Egress

Items to Verify

- Ladders provided every 25 ft

- Steps, ramps, or ladders secured

- Trench access kept clear

- Safe entry/exit available at all times

9. Atmosphere Testing

(Required for >1.2m depth and/or deep narrow trenches)

Items to Verify

- Oxygen levels normal

- No toxic gas detected

- Ventilation installed when needed

- Gas detectors calibrated and functional

10. Barricading, Warning Signs, and Visibility

Items to Verify

- Barriers placed around excavation

- Danger signage posted

- Night lighting adequate

- Reflective markers used

11. Worker Training and Awareness

Items to Verify

- Workers instructed on today’s hazards

- Toolbox Talk conducted

- Workers understand emergency procedure

- Workers wearing required PPE

12. Machinery and Equipment Interaction

Items to Verify

- Excavators & loaders operated by certified personnel

- Spotters assigned when working near trench

- Reverse alarms functional

- Operational clearance maintained

13. Emergency Preparedness

Items to Verify

- Emergency rescue plan available

- First aid kit accessible

- Emergency contact list posted

- Rescue equipment nearby

- Workers know communication signals

14. Daily Inspection Timing

The supervisor must inspect:

- Before start of shift

- After breaks

- After any weather change

- After any soil disturbance

- After installation of protective system

- After machinery movement near trench

Supervisor Responsibilities

Tasks they MUST complete daily

- Inspect trench personally

- Document findings

- Stop work if unsafe

- Correct hazards before authorizing entry

- Report conditions to HSE and management

- Ensure workers never enter unprotected trench

What Supervisors Must NEVER Allow

- Workers entering an unprotected trench

- Trench walls vertical in Type B/C soils

- Spoil piles on trench edges

- Workers jumping into trench

- Unauthorized modifications to shoring

- Equipment parked at trench edge

- Permits being used after expiration

Consequences of Failing Daily Excavation Checks

- Serious injuries and fatalities

- Utility strikes

- Structural collapses

- Legal liability for company and supervisor

- Project shutdown

- Fines and compliance violations

A supervisor carrying responsibility must treat trench safety as a life-critical discipline.

Conclusion

Daily excavation inspections are not paperwork — they are lifesaving checks that ensure the trench remains stable and safe for workers. By following this checklist consistently, supervisors exercise responsible control over excavation safety, reinforcing safe practices, maintaining compliance, and preventing accidents.

A safe trench is one that is inspected — every single day.

For checklist and templates visit The HSE Tools.

Permit to Work System in Excavation Activities

Shoring, Sloping and Benching: Protective Systems Explained

Soil Classification and Testing for Excavation Safety

Excavation Hazards and Their Control Measures

What Is Excavation Work? Definition, Types, and Safety Controls

FAQs

1. Who is responsible for daily trench inspection?

A trained and designated competent person — typically the excavation supervisor.

2. How often must inspection occur?

At least daily and after any hazard-altering condition.

3. Is a permit required daily?

Yes — the permit duration is shift-based or daily in most procedures.

4. Must every trench have a protective system?

If deeper than 1.2 meters or according to local standards — yes.

5. Can work proceed if the competent person is absent?

No — excavation must stop immediately.