Ventilation Requirements for Confined Spaces

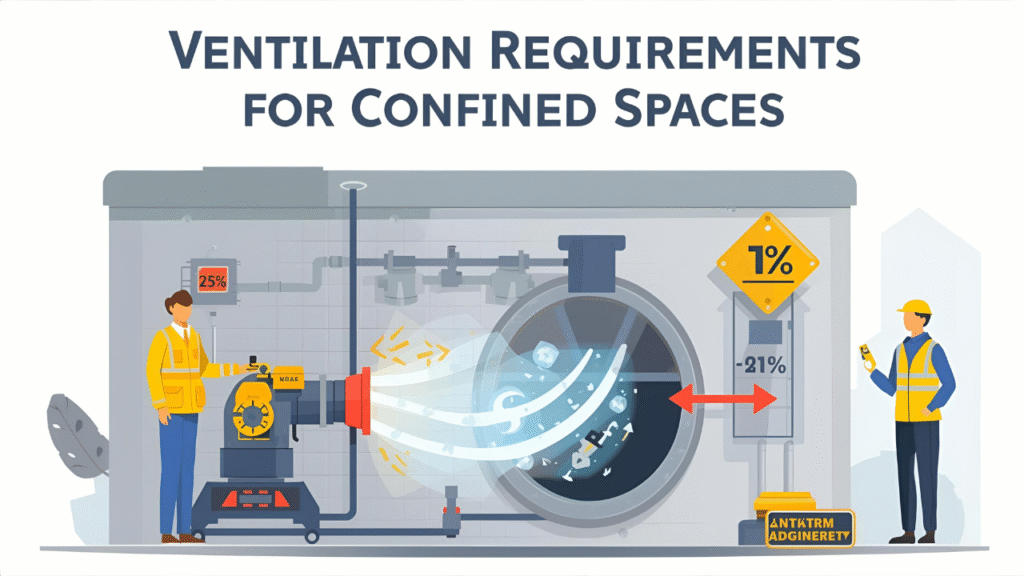

Confined spaces often contain hazardous atmospheres due to poor air circulation, gas accumulation, and oxygen displacement. Proper ventilation is essential to ensure that workers have safe breathing conditions and to prevent the build-up of toxic, flammable, or oxygen-deficient atmospheres.

Ventilation is not just recommended — in many cases, it is a regulatory requirement before and during confined space entry.

Why Ventilation Is Necessary in Confined Spaces

Ventilation is required to:

- Maintain safe oxygen levels

- Remove toxic contaminants

- Dilute flammable gases

- Control heat and humidity

- Improve worker comfort

- Reduce explosion risk

In a confined space with stagnant air, deadly gases can build up silently and quickly.

Natural vs. Mechanical Ventilation

Natural Ventilation

- Relies on passive air movement

- Can be unpredictable

- Not recommended for critical confined space entry

Mechanical Ventilation

Uses:

- Fans

- Blowers

- Air movers

- Ventilation ducts

Mechanical ventilation is the standard and required method for confined space safety.

Types of Mechanical Ventilation

1. Dilution Ventilation

Fresh air is introduced, and contaminated air is diluted.

Best for:

- Large spaces

- Non-toxic vapors

- Minimal gas concentrations

2. Local Exhaust Ventilation (LEV)

Air is extracted directly from gas source.

Examples:

- Extracting fumes from bottom of tank

- Removing vapors near solvent source

This method is targeted and efficient.

3. Supply Ventilation

Fresh air is forced into space.

Used when:

- Worker needs breathing quality air

- Contaminants are light gases floating upward

4. Combination (Push–Pull Ventilation)

Both supply of fresh air and removal of contaminated air used simultaneously.

Ventilation Flow Rate Requirements

Proper airflow ensures contaminants don’t accumulate.

Minimum ventilation rate:

20 air changes per hour is common practice for confined spaces.

In high-risk spaces:

- Higher flow rates required

- Gas concentrations continuously monitored

Understanding Gas Stratification and Ventilation Positioning

Different gases settle in different places due to density:

- Methane (lighter than air) → rises

- Hydrogen sulfide (heavier than air) → sinks

- Carbon monoxide (roughly equal density) → mixes evenly

Therefore:

- Air inlets and outlets must be positioned based on gas behavior

- Testing should be done at top, middle, and bottom

- Ventilation ducts must be properly placed

Ventilation Ducting and Hose Setup

Ventilation ducts ensure air reaches deep into enclosed areas.

Best practices:

- Position ducts near worker breathing zone

- Avoid dead-air pockets

- Extend hoses to bottom of pits or tanks

- Ensure hoses do not obstruct exits

- Prevent sharp bends that restrict airflow

Continuous Ventilation Requirement

Ventilation is NOT a one-time action.

Continuous ventilation must be used:

- During entry

- During work

- During cleaning

- During shutdown / breaks

- Until space is declared safe

Turning off ventilation even for a short time can allow gas concentration to rise rapidly.

Ventilation and Atmospheric Testing Work Together

Ventilation alone is NOT enough.

Atmosphere must be tested for:

- Oxygen content

- Flammable gases

- Toxic gases (CO, H₂S, etc.)

If ventilation fails — worker must evacuate immediately.

Ventilation for Heat Control

Confined spaces trap temperature.

Workers may experience:

- Heat stress

- Dehydration

- Heat stroke

High airflow improves thermal comfort and safety.

Acceptable Oxygen Levels After Ventilation

Safe range:

19.5% — 23.5% oxygen

If levels fall below 19.5%, workers cannot enter.

Example causes of oxygen deficiency:

- Rusting

- Chemical reactions

- Gas displacement

- Organic decomposition

Ventilation restores breathable air.

Ventilation and Permit-to-Work Requirements

Under permit-required confined space rules:

- Testing must be documented

- Ventilation must be confirmed

- Supervisor must sign approval

- Continuous monitoring is required

Permit is invalid if:

- Ventilation stops

- Hazards reappear

- Gas levels exceed safe limits

Equipment Used for Ventilation

Common systems:

- Portable axial fans

- Pneumatic blowers

- Explosion-proof fans

- Venturi-type air movers

- Flexible ducting systems

- Ventilated manhole blowers

Explosion-proof fans required if:

- Flammable gas may be present

- Risk of ignition exists

Ventilation Failures and What Causes Them

Typical issues:

- Blocked ducts

- Incorrect duct placement

- Fan too small for volume

- Gas source continuously generating

- Wrong airflow direction

- Fan malfunction

- Collapsed ducting

These failures can go unnoticed — and deadly gases return quickly.

Safety Precautions During Ventilation

Workers must:

- Never rely on smell to detect gas

- Trust gas detectors

- Keep PPE on

- Maintain communication with attendant

- Exit if alarm sounds

Supervisors must:

- Ensure accurate testing

- Confirm ventilation effectiveness

- Verify proper hose positioning

- Check equipment calibration

Special Ventilation Cases

Sewers

- H₂S and methane accumulation

- Exhaust ventilation needed from low points

Tanks and silos

- Vapors settle differently

- Blower must reach bottom

Pipes and ducts

- High length-to-diameter ratio

- Forced airflow required

Real Incident Example

A worker cleaning a storage tank collapsed due to oxygen deficiency.

Ventilation hose did not reach bottom of tank.

Air above was fine — bottom was oxygen-starved.

Gas detector worn at chest level did not detect low O₂ at worker’s feet.

Lesson: Ventilation placement matters.

Conclusion

Proper ventilation is one of the most important safety controls in confined spaces. It ensures breathable air, dilutes contaminants, prevents explosions, and protects workers from invisible atmospheric dangers. Workers must never enter a confined space unless ventilation is functioning, validated, and continuously monitored.

Ventilation saves lives — never compromise on it.

For checklist and templates visit The HSE Tools.

Confined Space Atmospheric Testing – Gas Detection Explained

Confined Space Entry Permit System Explained

Hazards Associated with Confined Spaces

What Is a Confined Space? Definition and Examples

Confined Space Safety Interview: 50 Questions and Sample Answers

FAQs

1. Is natural ventilation enough in confined spaces?

No — mechanical ventilation is required.

2. What is the minimum oxygen allowed inside?

19.5%

3. Should ventilation continue during the entire work period?

Yes — continuously.

4. Do you need atmospheric testing even if ventilated?

Absolutely — ventilation does not replace gas monitoring.

5. Can gas levels change even with ventilation?

Yes — if airflow is insufficient or gas is continuously generated.