Scaffolding Erection and Dismantling Procedure

Scaffolding is a critical temporary structure used to provide safe access and working platforms at height. While scaffolds support many construction and maintenance activities, they also present serious hazards if not erected or dismantled correctly. A large number of fall-from-height and collapse incidents occur during scaffolding erection and dismantling, making these phases the most dangerous in the scaffold lifecycle.

A well-defined Scaffolding Erection and Dismantling Procedure ensures that scaffolds are assembled safely, used correctly, and removed without exposing workers to unnecessary risks. This article provides a detailed, step-by-step explanation of safe erection and dismantling procedures, including planning, safety controls, inspections, and best practices.

Why Proper Scaffolding Procedures Are Critical

Scaffold accidents can result in:

- Fatal falls from height

- Scaffold collapse

- Falling objects injuring workers below

- Structural failure due to overloading

- Legal penalties and project delays

Following a proper procedure ensures compliance, protects workers, and maintains structural integrity throughout the scaffold’s use.

Legal and Safety Requirements for Scaffolding

Most national and international safety regulations require that:

- Scaffolds are erected and dismantled by competent persons

- Risk assessments are conducted

- Fall protection is provided during erection and dismantling

- Scaffolds are inspected and tagged before use

Failure to comply can lead to severe legal and safety consequences.

Roles and Responsibilities in Scaffolding Work

Management Responsibilities

- Provide approved scaffold materials

- Ensure competent scaffolders are appointed

- Provide training and fall protection equipment

- Approve scaffold plans and permits

Scaffold Supervisor Responsibilities

- Supervise erection and dismantling

- Ensure procedures are followed

- Verify scaffold stability

- Arrange inspections and tagging

Scaffolders Responsibilities

- Follow approved erection sequence

- Use PPE and fall protection

- Report damaged components

- Maintain safe work practices

Safety Officer Responsibilities

- Review risk assessments

- Audit scaffold safety

- Verify compliance with standards

- Support training and inspections

Pre-Erection Planning for Scaffolding

Scaffold Design and Selection

Before erection begins, determine:

- Type of scaffold required

- Height and load capacity

- Duration of use

- Access and egress requirements

- Environmental conditions

Complex scaffolds may require engineered drawings.

Risk Assessment and Permit to Work

A task-specific risk assessment must identify:

- Fall hazards

- Ground stability risks

- Falling object hazards

- Weather-related risks

For high or complex scaffolds, a Permit to Work must be issued.

Inspection of Scaffold Materials

All components must be inspected before use.

Check for:

- Bent or corroded tubes

- Cracked or damaged planks

- Defective couplers

- Missing components

Damaged materials must be removed from service.

Ground Preparation

Scaffold foundations must be strong and level.

Ensure:

- Firm ground conditions

- Use of sole boards and base plates

- Proper drainage to avoid settlement

Poor foundations are a major cause of scaffold collapse.

Personal Protective Equipment for Scaffolders

Mandatory PPE includes:

- Safety helmet with chin strap

- Full-body harness with lanyard

- Safety shoes with anti-slip soles

- Gloves

- High-visibility vest

Fall protection is essential during erection and dismantling.

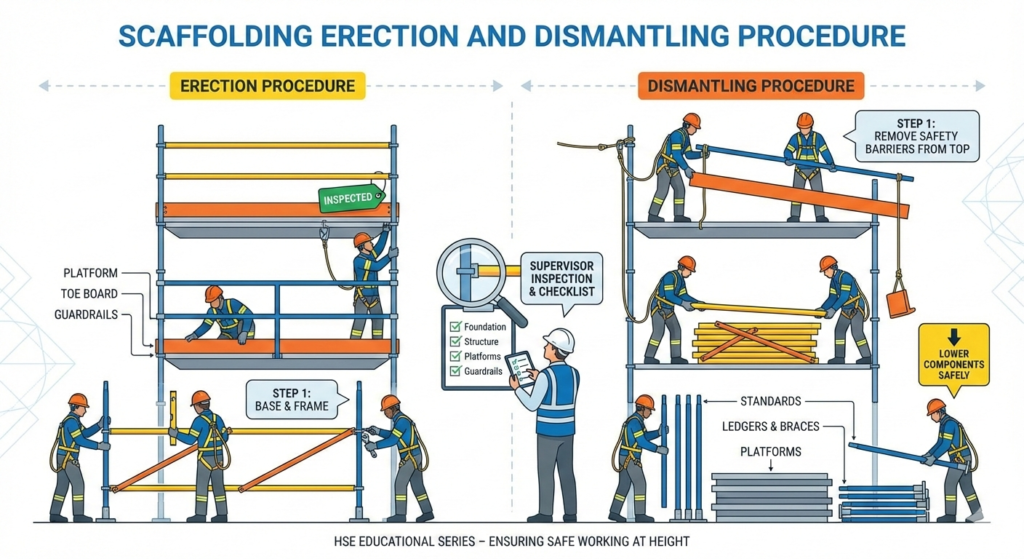

Scaffolding Erection Procedure

Step 1: Establish the Scaffold Base

- Mark the scaffold layout

- Place sole boards on firm ground

- Install base plates on sole boards

- Ensure bases are level and aligned

The base determines overall scaffold stability.

Step 2: Install Standards (Vertical Members)

- Fix standards vertically on base plates

- Maintain correct spacing as per design

- Ensure standards are plumb

Standards transfer load to the ground.

Step 3: Fix Ledgers and Transoms

- Connect ledgers horizontally between standards

- Install transoms at right angles

- Secure all connections with approved couplers

These components provide structural strength.

Step 4: Install Bracing

- Fix diagonal and horizontal braces

- Ensure bracing is installed as per design

Bracing prevents sway and collapse.

Step 5: Progressive Platform Installation

- Install working platforms as erection progresses

- Use scaffold planks or steel decks

- Secure platforms properly

Workers should not stand on incomplete decks.

Step 6: Install Guardrails and Toe Boards

- Install top and mid guardrails

- Fix toe boards at platform edges

Edge protection must be installed as early as possible.

Step 7: Provide Safe Access

- Install ladders or stair towers

- Secure access points

- Ensure safe entry and exit

Climbing on scaffold frames is prohibited.

Step 8: Implement Fall Protection During Erection

- Use advance guardrail systems or

- Use harnesses connected to secure anchor points

Scaffolders are exposed to fall risk during erection.

Step 9: Complete Scaffold and Final Inspection

- Verify all components are installed

- Check alignment and stability

- Ensure load capacity is not exceeded

Step 10: Scaffold Tagging and Handover

- Inspect scaffold by competent person

- Attach scaffold tag

- Green tag indicates safe for use

No one should use an untagged scaffold.

Scaffolding Dismantling Procedure

Dismantling is as hazardous as erection and must follow a controlled process.

Pre-Dismantling Preparation

- Obtain dismantling permit if required

- Ensure scaffold is no longer in use

- Barricade the area below

- Inspect scaffold condition

Step 1: Remove Materials and Debris

- Clear tools and materials from platforms

- Ensure platforms are empty

Step 2: Remove Access Components

- Remove ladders or stair towers last used

- Maintain safe access until dismantling is complete

Step 3: Remove Guardrails and Toe Boards

- Remove edge protection systematically

- Use fall protection during removal

Step 4: Remove Platforms

- Remove planks or decks level by level

- Do not throw materials down

Step 5: Remove Bracing, Transoms, and Ledgers

- Dismantle in reverse order of erection

- Maintain stability at all times

Step 6: Remove Standards

- Remove standards last

- Ensure no load remains

Step 7: Lower and Stack Materials Safely

- Use ropes or mechanical aids

- Stack materials neatly

- Inspect components for damage

Safety Precautions During Erection and Dismantling

- Never work in high winds or rain

- Never overload scaffolds

- Do not modify scaffold without approval

- Maintain exclusion zones below

- Use proper communication

Common Causes of Scaffolding Accidents

- Missing guardrails

- Inadequate bracing

- Poor foundations

- Untrained scaffolders

- Ignoring procedures

Inspection and Maintenance Requirements

Scaffolds must be inspected:

- Before first use

- Daily before work

- After modification

- After adverse weather

Records of inspection must be maintained.

Best Practices for Safe Scaffolding Work

- Use competent scaffolders only

- Follow approved designs

- Implement fall protection early

- Conduct regular training

- Enforce tagging systems

Conclusion

The Scaffolding Erection and Dismantling Procedure is a critical safety process that directly affects worker safety at height. By following a structured, step-by-step approach — supported by planning, training, supervision, and inspection — organizations can significantly reduce scaffold-related accidents.

Remember, most scaffold accidents occur during erection and dismantling. Doing these tasks safely is not optional — it is essential.

For checklist and templates visit The HSE Tools.

Scaffold Components and Types Explained

Roof Work Safety: Do’s and Don’ts

Common Causes of Falls and Their Prevention

Permit to Work for Height-Related Activities

Scaffold Erection and Dismantling Safety Procedures

FAQs

1. Who is allowed to erect and dismantle scaffolding?

Only trained and competent scaffolders.

2. Is fall protection required during scaffold erection?

Yes, fall protection is mandatory.

3. When should scaffolds be inspected?

Before use, daily, and after any modification.

4. Can scaffolding be dismantled in any order?

No, it must be dismantled in reverse order of erection.

5. What is the purpose of scaffold tagging?

To indicate whether a scaffold is safe for use.