Safe Load Limits for Scaffolding Platforms

Understand safe load limits for scaffolding platforms, including load types, duty ratings, common mistakes, and control measures to prevent scaffold overloading and collapse.

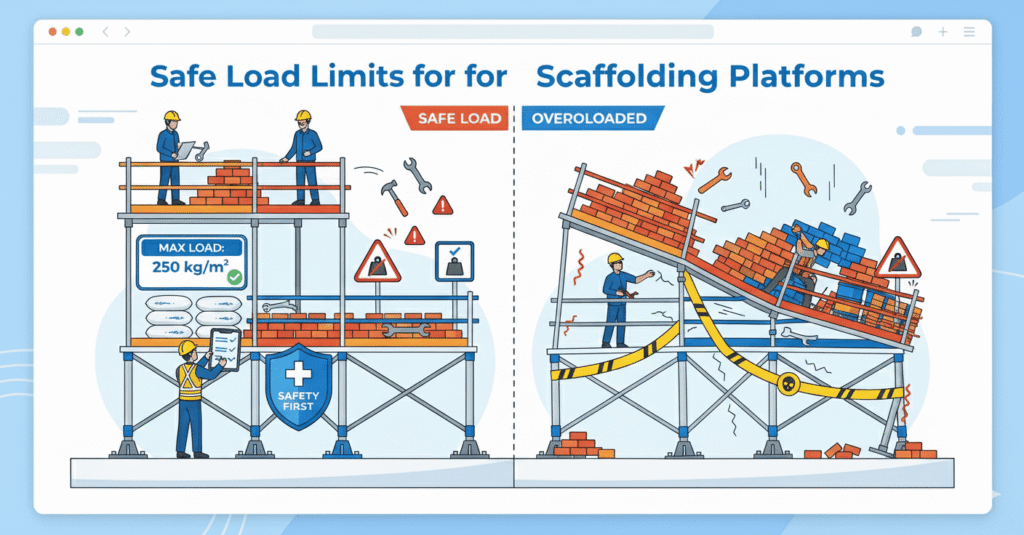

Scaffolding platforms are designed to provide safe access and working space at height, but their safety depends heavily on not exceeding safe load limits. Overloading is one of the leading causes of scaffold collapse, platform failure, and serious injuries. Many scaffold accidents occur not because of poor erection, but because too many workers, materials, or equipment are placed on the platform at the same time.

Understanding safe load limits for scaffolding platforms is essential for scaffolders, supervisors, engineers, and safety officers. This article explains scaffold load concepts, types of loads, load ratings, common overloading causes, and practical control measures to ensure scaffolds remain safe under all working conditions.

Why Safe Load Limits Are Critical for Scaffolding

Scaffold platforms are temporary structures with defined load-carrying capacity. When these limits are exceeded, the scaffold may:

- Collapse suddenly

- Fail at weak points such as planks or couplers

- Tilt or overturn

- Cause falls from height

- Drop materials onto people below

Respecting load limits protects workers’ lives, prevents structural failure, and ensures compliance with safety regulations.

What Are Safe Load Limits in Scaffolding?

Safe load limits, also known as Safe Working Load (SWL), refer to the maximum load a scaffolding platform can safely support under normal working conditions. This load includes:

- Weight of workers

- Weight of tools and equipment

- Weight of stored materials

- Dynamic loads caused by movement

Exceeding the SWL significantly increases the risk of failure.

Types of Loads Acting on Scaffolding Platforms

Understanding load types helps in accurate load planning.

Dead Load

Dead load is the constant weight of the scaffold itself.

Includes:

- Scaffold tubes

- Planks or decks

- Guardrails

- Toe boards

Dead load is considered during scaffold design and cannot be changed.

Live Load

Live load includes all variable loads placed on the scaffold.

Includes:

- Workers

- Tools

- Materials

- Equipment

Live load must always remain within allowable limits.

Impact and Dynamic Load

Dynamic load occurs due to movement.

Examples:

- Workers walking or climbing

- Lifting or dropping materials

- Use of power tools

Dynamic loads increase stress on the scaffold and must be minimized.

Environmental Load

Environmental loads come from external forces.

Includes:

- Wind pressure

- Rain accumulation

- Snow or ice

Environmental loads can reduce scaffold capacity and stability.

Scaffold Duty Ratings and Load Classes

Scaffolds are classified based on intended load capacity.

Light Duty Scaffolds

Typical Use

- Painting

- Inspection

- Light maintenance

Load Capacity

- Low material storage

- Generally limited to one or two workers

Medium Duty Scaffolds

Typical Use

- Bricklaying

- Plastering

- General construction

Load Capacity

- Moderate material storage

- Multiple workers

Heavy Duty Scaffolds

Typical Use

- Heavy masonry

- Industrial construction

- Large equipment installation

Load Capacity

- High material storage

- Heavy tools and equipment

Special Duty Scaffolds

Typical Use

- Designed for specific applications

Load Capacity

- As per engineering design

Load ratings must always be confirmed from scaffold design or manufacturer data.

Understanding Load Distribution on Scaffolding Platforms

Even when total load is within limits, uneven load distribution can cause failure.

Concentrated Loads

Concentrated loads occur when heavy items are placed in one area.

Examples:

- Stacked bricks in one corner

- Heavy equipment placed on a single plank

Uniformly Distributed Loads

Uniform load distribution spreads weight evenly across the platform, reducing stress.

Control Measures

- Spread materials evenly

- Avoid stacking materials in one location

- Use additional platforms if required

Common Causes of Scaffold Overloading

Excessive Material Storage

Workers often store materials on platforms for convenience.

Risk

- Overloading beyond design capacity

Control

- Limit materials to immediate use only

Too Many Workers on One Platform

Multiple workers performing tasks simultaneously increase live load.

Control

- Limit number of workers per platform

- Plan work activities

Heavy Equipment on Scaffolds

Placing generators, welding machines, or compressors on scaffolds is dangerous.

Control

- Use ground-based equipment

- Confirm load capacity before placement

Lack of Awareness of Load Limits

Workers often do not know scaffold load ratings.

Control

- Display load limits clearly

- Conduct training and toolbox talks

Unauthorized Scaffold Modifications

Removing or altering components reduces load capacity.

Control

- Prohibit unauthorized changes

- Enforce scaffold tagging system

Control Measures to Maintain Safe Load Limits

Proper Scaffold Design and Planning

- Select correct scaffold type

- Determine load requirements before erection

- Use engineered designs for heavy-duty scaffolds

Display Load Rating Information

- Clearly display scaffold load class

- Use signage or scaffold tags

Workers should know the maximum allowed load.

Material Management on Scaffolds

- Store only required materials

- Remove excess materials daily

- Avoid stockpiling

Use of Scaffold Tags

Scaffold tags should indicate:

- Load class

- Inspection status

- Usage restrictions

Regular Inspection and Monitoring

Daily inspections should check for:

- Signs of overloading

- Bent components

- Sagging platforms

Immediate action must be taken if overloading is suspected.

Training and Awareness

Training should cover:

- Load types

- Load limits

- Safe material storage

- Consequences of overloading

Educated workers are less likely to overload scaffolds.

Special Considerations for Different Scaffold Types

Mobile Scaffolds

- Lower load capacity

- No material storage allowed

- Wheels must be locked

Suspended Scaffolds

- Strict load limits

- Balanced loads essential

- Overloading can cause suspension failure

Cantilever Scaffolds

- High risk of overturning

- Requires engineered design

- Load limits strictly controlled

Weather Impact on Scaffold Load Capacity

Environmental conditions can reduce safe load limits.

Wind Effects

- Wind pressure adds lateral load

- Can destabilize scaffold

Control

- Reduce loads during high winds

- Secure materials

Rain and Water Accumulation

- Increases platform weight

- Makes surfaces slippery

Control

- Ensure proper drainage

- Suspend work during heavy rain

Snow or Ice

- Adds significant dead load

- Increases slip risk

Control

- Clear platforms before use

- Reassess load capacity

Inspection Checklist Related to Load Safety

Safety officers should verify:

- Load rating signage present

- No excessive materials

- Even load distribution

- No sagging or bending

- Scaffold ties intact

Role of Safety Officers in Load Control

Safety officers must:

- Verify scaffold design

- Educate workers

- Monitor material storage

- Stop work if overloading is observed

Their proactive role prevents serious incidents.

Integration with Permit to Work System

For heavy-duty or high-risk scaffolds:

- Load limits must be referenced in the Permit to Work

- Permit should specify material limits

- Supervisor must verify compliance

Common Myths About Scaffold Load Limits

- “It looks strong, so it’s safe”

- “A little extra load won’t matter”

- “Scaffold hasn’t collapsed before”

These assumptions have caused many accidents.

Best Practices for Maintaining Safe Load Limits

- Plan material delivery schedules

- Use lifting equipment to move materials

- Enforce housekeeping rules

- Inspect platforms daily

- Never exceed design limits

Conclusion

Maintaining safe load limits for scaffolding platforms is a fundamental requirement for work at height safety. Overloading scaffolds is a silent hazard that can lead to sudden and catastrophic failures. By understanding load types, respecting load ratings, managing materials effectively, and enforcing strict inspection and supervision, organizations can prevent scaffold collapses and protect workers’ lives.

Always remember — a scaffold is only as safe as the load it carries.

For checklist and templates visit The HSE Tools.

Common Scaffolding Hazards and Control Measures

Daily Scaffold Inspection Checklist for Safety Officers

Scaffolding Erection and Dismantling Procedure

Scaffold Components and Types Explained

Roof Work Safety: Do’s and Don’ts

FAQs

1. What happens if a scaffold is overloaded?

It can collapse, fail structurally, or cause falls and injuries.

2. Who decides the safe load limit of a scaffold?

The scaffold designer, manufacturer, or engineer.

3. Can materials be stored on scaffolding platforms?

Yes, but only within approved load limits.

4. Should load limits be displayed on scaffolds?

Yes, load rating must be clearly visible.

5. How can overloading be prevented?

Through planning, training, inspection, and supervision.