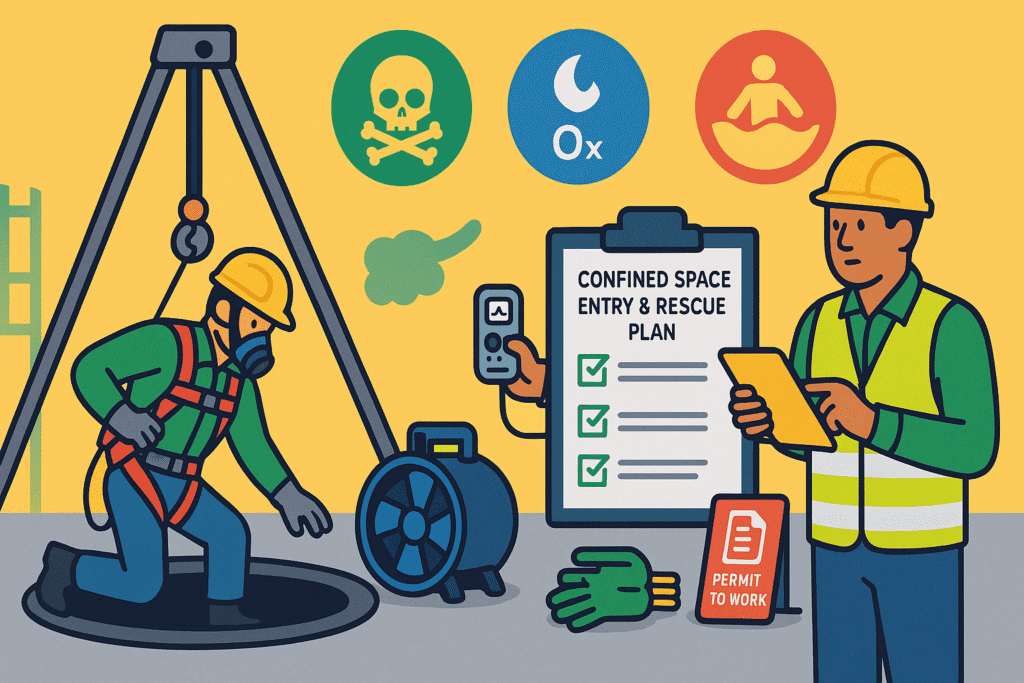

Hazards and Risks in Confined Spaces: Entry & Rescue Plans

Confined spaces are among the most dangerous workplaces. They often contain hidden hazards such as toxic gases, limited oxygen, or engulfment risks. Every year, workers lose their lives because hazards are not identified or proper rescue plans are not in place. This article explains the key hazards and risks in confined spaces, outlines safe entry procedures, and highlights the importance of rescue plans.

1. What is a Confined Space?

A confined space is any area that:

- Is large enough for a worker to enter and perform work.

- Has limited or restricted entry/exit.

- Is not designed for continuous occupancy.

Examples: Tanks, silos, sewers, manholes, pipelines, pits, and vaults.

2. Common Hazards and Risks in Confined Spaces

2.1 Atmospheric Hazards

- Oxygen deficiency (below 19.5%).

- Toxic gases (hydrogen sulfide, carbon monoxide).

- Flammable vapours.

Risks: Asphyxiation, poisoning, explosions.

2.2 Engulfment Hazards

- Loose materials like grain, sand, or sludge can engulf workers.

Risks: Suffocation or crushing injuries.

2.3 Physical Hazards

- Moving equipment, sharp edges, slippery surfaces, or electrical hazards.

Risks: Injuries or electrocution.

2.4 Configuration Hazards

- Narrow passages, sloping floors, or converging walls can trap or injure workers.

2.5 Psychological Hazards

- Claustrophobia or panic attacks inside confined spaces.

3. Entry Procedures for Confined Spaces

3.1 Hazard Assessment

- Conduct a thorough assessment before entry.

- Identify all potential atmospheric, physical, and engulfment hazards.

3.2 Permit-to-Work System

- Use a confined space entry permit to control access.

- Ensure only authorised and trained personnel enter.

3.3 Atmospheric Testing

- Test for oxygen level, flammable gases, and toxic substances before and during entry using calibrated monitors.

3.4 Ventilation

- Provide forced or natural ventilation to maintain safe air quality.

3.5 Isolation

- Lockout/tagout energy sources to prevent accidental startup.

- Isolate pipelines and inlets.

3.6 Communication

- Maintain constant communication between entrants and attendants.

3.7 PPE

- Respiratory protection, harnesses, helmets, gloves, and lighting as required.

4. Rescue Plans for Confined Spaces

4.1 Importance of Rescue Plans

Most fatalities occur when co-workers attempt unplanned rescues. A written rescue plan is essential before entry.

4.2 Elements of a Rescue Plan

- Designated Rescue Team: Trained and equipped.

- Rescue Equipment: Tripods, winches, retrieval lines, breathing apparatus.

- Practice Drills: Regular mock drills for all personnel.

- Coordination with Emergency Services: Notify local fire or rescue teams if needed.

4.3 Types of Rescue

- Non-Entry Rescue: Using retrieval systems without sending another person in.

- Entry Rescue: Only by trained rescuers with full PPE and backup support.

5. Training and Documentation

- Train workers in hazard recognition, permit procedures, and emergency response.

- Maintain records of atmospheric tests, permits, training, and rescue drills.

- Review and update procedures regularly.

For detailed guidance, visit OSHA’s Confined Space Standards.

Exam-Oriented Questions with Detailed Answers

Short Answer Questions

Q1. Define a confined space and give two examples.

Answer: A confined space is an area with limited entry/exit not designed for continuous occupancy. Examples: tanks and sewers.

Q2. List three common atmospheric hazards in confined spaces.

Answer: Oxygen deficiency, toxic gases, and flammable vapours.

Q3. Why is a rescue plan necessary before confined space entry?

Answer: To ensure safe, coordinated rescue and prevent additional fatalities from unplanned rescues.

Long Answer Questions

Q1. Describe the main hazards associated with confined spaces.

Answer: Hazards include atmospheric risks (oxygen deficiency, toxic gases), engulfment (loose materials), physical hazards (moving parts, electricity), configuration hazards (narrow spaces), and psychological stress. Each hazard can cause injury or death without controls.

Q2. Explain the step-by-step procedure for safe confined space entry.

Answer: Conduct hazard assessment, issue a permit, test the atmosphere, ventilate, isolate energy sources, maintain communication, and provide appropriate PPE. These steps protect workers from asphyxiation, poisoning, or injury.

Q3. Discuss the key components of a confined space rescue plan.

Answer: A rescue plan should designate trained rescuers, provide appropriate equipment (tripods, winches, breathing apparatus), include practice drills, and coordinate with emergency services. Non-entry rescue should be prioritised, with entry rescue as a last resort.

Scenario-Based Questions

Q1. Workers enter a tank without testing the atmosphere and collapse. What went wrong?

Answer: They failed to perform atmospheric testing and hazard assessment. Controls should include pre-entry testing, ventilation, permits, and standby attendants with rescue equipment.

Q2. A confined space entry permit expires during work. What should be done?

Answer: Stop work, evacuate the space, re-assess hazards, re-test atmosphere, and issue a new permit if safe.

Q3. A co-worker collapses in a confined space. How should rescuers respond?

Answer: Do not enter without a plan. Call emergency services, attempt non-entry rescue using retrieval systems, and only trained personnel with proper PPE should enter if absolutely necessary.

Frequently Asked Questions (FAQs)

1. What defines a confined space under OSHA?

Answer: An area large enough for entry, with limited entry/exit, not designed for continuous occupancy, and containing potential hazards.

2. How often should confined space air monitoring be performed?

Answer: Before entry and continuously during occupancy.

3. Who can issue a confined space entry permit?

Answer: An authorised and competent person trained in confined space procedures.

4. What is the difference between non-entry and entry rescue?

Answer: Non-entry uses retrieval systems without sending rescuers in; entry requires trained rescuers entering the space with full PPE.

5. Are rescue drills mandatory?

Answer: Yes. Regular drills ensure teams are prepared and equipment works correctly.

6. What’s the role of a confined space attendant?

Answer: To monitor conditions, maintain communication, and initiate rescue procedures if necessary.

6. Conclusion

Confined spaces present unique and deadly hazards. Identifying risks, implementing strict entry procedures, and having a well-rehearsed rescue plan are vital to saving lives. Safety professionals must ensure training, documentation, and continuous monitoring to keep workers safe in these high-risk environments.

Identifying and Controlling Hazards in Manufacturing Plants

Common Hazards in Construction Sites and How to Control Them

Engineering Controls vs Administrative Controls vs PPE

Task Based Risk Assessment (TBRA): A Step-by-Step Guide

How to Conduct a Job Safety Analysis (JSA) to Identify Hazards

Sir jo app nay you tube par vedio dalay hay safety say Related Kiya unka PDF mil sakta hay