5 Levels of Risk Control (Hierarchy of Controls) Explained

The Hierarchy of Controls is one of the most important principles in occupational health and safety. It provides a structured way to control hazards by prioritizing the most effective measures.

Understanding and applying these five levels helps organizations minimize workplace risks and protect employees from injury or illness. This article explains each level in detail, with examples, applications, and practical guidance.

What is the Hierarchy of Controls?

The Hierarchy of Controls is a step-by-step approach to reducing workplace hazards, ranking control methods from most effective to least effective.

It is widely used in safety management systems, including ISO 45001, OSHA, and NEBOSH, to ensure that risks are controlled in the most reliable way.

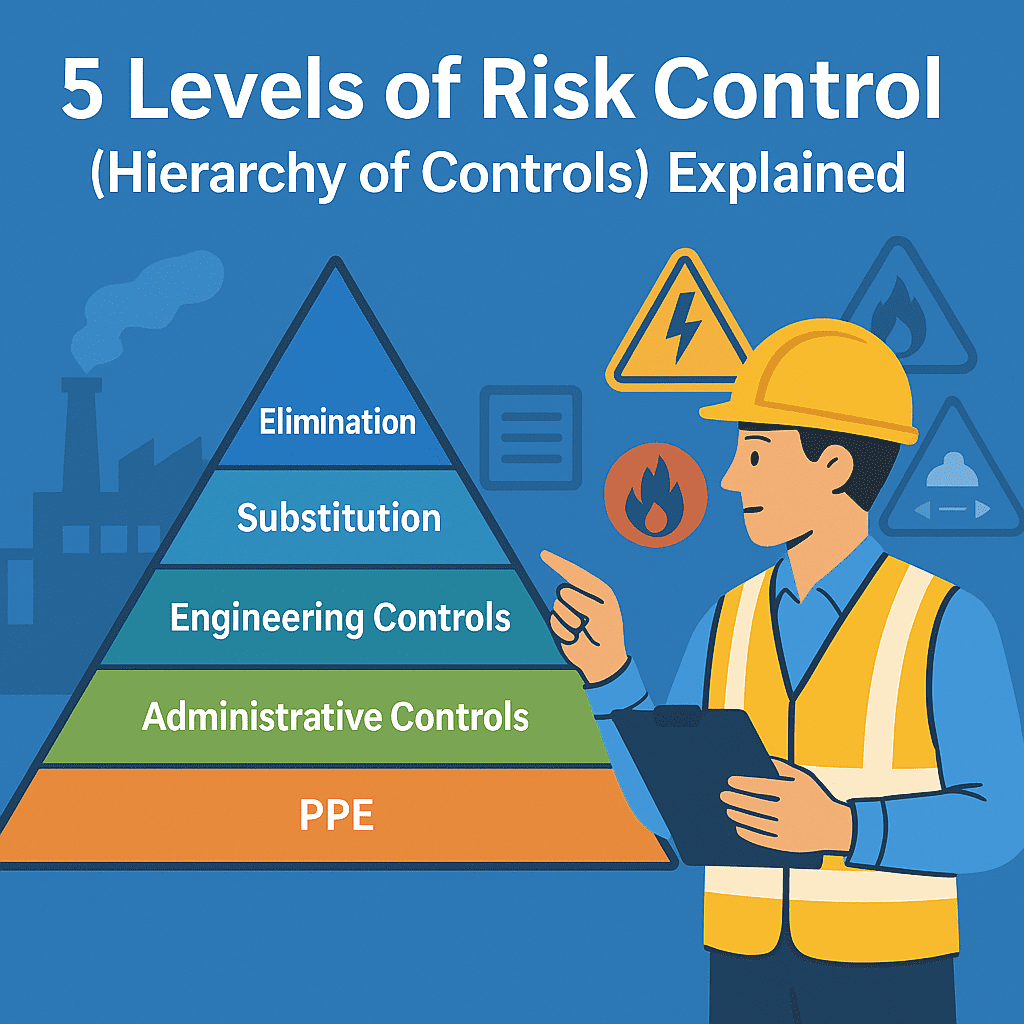

The five levels of risk control are:

- Elimination

- Substitution

- Engineering Controls

- Administrative Controls

- Personal Protective Equipment (PPE)

The goal is always to start from the top of the hierarchy (Elimination) before considering lower levels like PPE, which should be the last line of defense.

Why the Hierarchy of Controls Matters

- Helps safety professionals choose the most effective control measures.

- Reduces dependence on human behavior (which can fail).

- Promotes a proactive safety culture.

- Meets international compliance standards.

- Reduces incident rates and compensation costs.

The Five Levels of Risk Control Explained

Let’s explore each level in detail.

1. Elimination – Remove the Hazard Completely

Definition:

Elimination means physically removing the hazard so that there is no longer any risk associated with it. It is the most effective method of control.

Example:

- Replacing manual lifting of heavy materials with automated conveyors.

- Stopping the use of a toxic chemical entirely.

- Designing out a fall hazard by installing equipment at ground level.

Benefits:

- Completely removes exposure to the hazard.

- No ongoing maintenance or PPE required.

Limitations:

- Not always practical, especially in existing processes.

- May involve redesigning equipment or work areas.

2. Substitution – Replace the Hazard

Definition:

Substitution involves replacing a hazardous material, process, or activity with one that is less dangerous.

Example:

- Using a water-based paint instead of a solvent-based one.

- Replacing diesel-powered tools with battery-operated ones to reduce fumes.

- Substituting a manual welding process with robotic welding.

Benefits:

- Significantly reduces risk while maintaining productivity.

- Often inexpensive compared to engineering redesigns.

Limitations:

- The substitute must not introduce new risks.

- Requires thorough evaluation before implementation.

3. Engineering Controls – Isolate People from the Hazard

Definition:

Engineering controls are physical modifications to equipment, workstations, or the environment that reduce exposure to hazards.

Example:

- Installing machine guards to prevent contact with moving parts.

- Using local exhaust ventilation to remove fumes.

- Designing soundproof enclosures around noisy machines.

Benefits:

- Controls the hazard at its source.

- Reduces dependency on worker behavior.

Limitations:

- Can be expensive to install.

- Requires ongoing maintenance to remain effective.

4. Administrative Controls – Change the Way People Work

Definition:

Administrative controls involve implementing policies, procedures, and training to reduce exposure to hazards.

Example:

- Rotating employees to reduce repetitive strain.

- Scheduling noisy work during shifts with fewer workers present.

- Displaying warning signs and safety instructions.

- Implementing standard operating procedures (SOPs).

Benefits:

- Inexpensive and quick to implement.

- Reinforces a strong safety culture.

Limitations:

- Depends heavily on worker compliance.

- Does not remove the hazard, only limits exposure.

5. Personal Protective Equipment (PPE) – Protect the Worker

Definition:

PPE is equipment worn by workers to protect them from residual hazards that cannot be eliminated through other means.

Examples:

- Helmets, gloves, goggles, face shields, earplugs, and safety boots.

- Respirators when working with dust, fumes, or vapors.

- Fall arrest systems when working at height.

Benefits:

- Provides immediate protection.

- Essential for emergency or temporary situations.

Limitations:

- Least effective control measure.

- Relies on correct use, maintenance, and worker behavior.

- Does not reduce or remove the hazard itself.

Hierarchy of Controls Diagram (Suggested Graphic)

To help visualize the hierarchy, imagine a pyramid with the most effective methods at the top:

- Elimination – Most Effective

- Substitution

- Engineering Controls

- Administrative Controls

- PPE – Least Effective

The higher the control, the more reliable and permanent it is.

Practical Example: Applying the Hierarchy of Controls

Scenario: Controlling exposure to welding fumes.

| Control Level | Example Control Measure |

|---|---|

| Elimination | Outsource welding to a facility with automated systems. |

| Substitution | Use low-fume or flux-cored welding rods. |

| Engineering Control | Install local exhaust ventilation and fume extraction systems. |

| Administrative Control | Limit exposure time and provide welding training. |

| PPE | Supply approved respirators and face shields. |

By applying the hierarchy, the risk is reduced at multiple levels, starting from elimination down to PPE.

How to Choose the Right Control

When selecting a control measure, always consider the following:

- Can the hazard be completely removed?

- If not, can it be substituted or isolated?

- What engineering options are available?

- What procedures and training are needed?

- What PPE will protect against residual risk?

Always document your decision process in the risk assessment report to show due diligence.

Common Mistakes to Avoid

- Relying solely on PPE instead of higher-order controls.

- Failing to evaluate new risks introduced by substitution.

- Ignoring worker feedback on control effectiveness.

- Not maintaining engineering controls regularly.

- Treating administrative measures as permanent solutions.

Benefits of Applying the Hierarchy of Controls

- Reduces accident frequency and severity.

- Improves compliance with OSHA and ISO standards.

- Enhances safety culture and employee confidence.

- Lowers insurance and compensation costs.

- Increases operational efficiency and productivity.

Conclusion

The Hierarchy of Controls is a cornerstone of occupational safety. By applying it systematically, safety professionals can effectively reduce or eliminate hazards in the workplace.

Always begin at the top of the hierarchy—aim for elimination or substitution first—and move down only when higher controls are not feasible.

Remember, PPE is the last line of defense, not the first. A proactive, layered approach to hazard control ensures a safer, healthier, and more productive workplace for everyone.

How to Conduct a Workplace Risk Assessment (Step-by-Step Guide)

Permit to Work System vs Risk Assessment

JSA vs JHA: Job Safety Analysis vs Job Hazard Analysis

Learning from Major Accidents: Bhopal, Piper Alpha, and Rana Plaza

Fire and Explosion Hazards in Chemical Industries

For checklist & templates visit The HSE Tools.