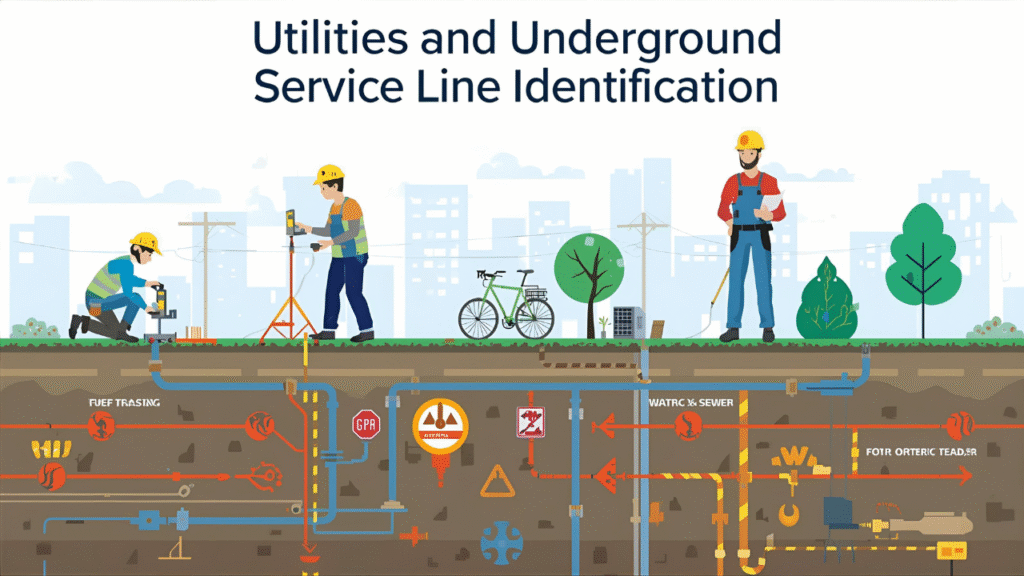

Utilities and Underground Service Line Identification

Excavation activities often intersect with underground utilities including gas pipelines, electrical cables, water networks, sewage lines, communication tunnels, and fiber optic systems. Striking any of these utilities can result in catastrophic consequences ranging from electrocution, gas explosions, and major service outages to severe environmental contamination.

Identifying and locating underground service lines prior to excavation is not just a best practice — it is a mandatory safety requirement in most jurisdictions. This article explains the types of underground utilities, methods for detection, mapping techniques, regulatory responsibilities, and on-site precautions for safe excavation.

Types of Underground Service Lines

Understanding what lies beneath the soil is the first step in planning safe digging.

Common Utility Systems Found Underground

- Electrical power lines

- Gas pipelines (natural gas, LPG)

- Water supply lines

- Sewer and drainage pipelines

- Telecommunications & fiber optic cables

- Oil pipelines

- Irrigation lines

- Steam pipelines

- District heating systems

- Traffic light & signal control cables

Different utilities have different risk levels and detection priority.

Risks Associated with Striking Underground Utilities

Potential Hazards

- Electrocution

- Gas explosion or fire

- Flooding from water mains

- Communication outages

- Chemical leaks

- Environmental contamination

- Financial losses

- Service disruption to communities

Sometimes the excavator operator is injured — but often the consequences extend far beyond the site.

Pre-Excavation Research and Utility Records

Before digging, groundwork must be done using:

Utility Records & Drawings

- Site utility maps

- Municipal utility archives

- Utility company diagrams

- GIS (Geographic Information Systems)

- Engineering drawings

- As-built drawings

- Survey data from previous construction

However, records can be incomplete or inaccurate, so further site verification is required.

Utility Marking & Color-Coding Standards

Many countries follow standardized utility marking systems.

Common Utility Marking Colors

- Red — electricity

- Yellow — gas, oil, petroleum

- Blue — potable water

- Green — sewage and drainage

- Orange — telecommunications / fiber optics

- Purple — reclaimed water / irrigation

- White — proposed excavation

These markings ensure visual clarity and reduce risk.

On-Site Utility Location Methods

1. Surface Marking and Flagging

Uses spray paint or flags.

2. Electronic Cable Locators

Handheld devices using:

- Electromagnetic induction

- Radio detection

Can trace conductive utilities such as electrical lines and metal pipes.

3. Ground Penetrating Radar (GPR)

- Detects non-metallic objects

- Can identify plastic, ceramic, and PVC pipes

- Generates sub-surface imaging

4. Acoustic / Pressure Testing for Pipes

Used to detect:

- Water leaks

- Flow patterns

- Cavitation in pipes

5. Trial Hole / Manual Test Pits

Physical verification using small controlled hand digging.

6. Vacuum Excavation / Hydro-Vac Methods

Sucks soil using pressurized air or water:

- Minimizes risk

- Used near sensitive utilities

Permit-to-Dig Requirements

Before breaking ground, a dedicated Permit-to-Dig must be issued.

Permit-to-Dig Includes:

- Utility map review

- On-site scanning confirmation

- Responsible persons identified

- Digging method approved

- Monitoring plan defined

- Emergency response defined

No permit = no excavation.

Roles and Responsibilities

Utility Owner / Authority

- Provides accurate records

- Assists in marking utilities

Excavation Supervisor

- Ensures records are followed

- Oversees detection procedures

Competent Person

- Verifies conditions daily

- Approves excavation entry

Excavation Crew

- Follows safe digging procedures

- Reports abnormal findings

Everyone plays a part in preventing underground strikes.

Safe Digging Techniques Near Utilities

Mandatory Practices

- Never use heavy machinery near identified utilities

- Use manual digging methods

- Allow safe clearance distances

- Avoid aggressive soil removal

- Probe soil carefully

- Do not use metal bars near electrical lines

Proper technique prevents damage.

Clearance Distances for Utility Lines

Typical Safety Distance:

- Electrical cables — 0.5 m minimum

- Gas pipelines — 1.0 m minimum

- Fiber optics — 0.5 m

When closer digging is required — hand tools only.

Temporary Utility Protection Measures

Physical Protection Methods

- Covering utilities with protective boards

- Installing trench plates

- Reinforcing utilities with shielding

- Re-routing cables if necessary

Daily Utility Monitoring and Inspection

Supervisory Checks

- Utility maps reviewed daily

- Changes in marking checked

- Signs of pipe leakage monitored

- Sounds, smells, vibrations observed

Example:

A faint gas odor must trigger immediate shutdown.

Emergency Procedures for Utility Strikes

If a gas line ruptures:

- Stop work

- Evacuate area

- Avoid ignition sources

- Notify gas provider immediately

If an electrical line is struck:

- Stay inside excavator

- Avoid touching ground

- Call utility company

- Only leave machine if on fire — jumping clear with both feet together

Safety knowledge here is critical for survival.

Documentation and Record Keeping

Must retain:

- Utility drawings

- Scanning reports

- GPR images

- Permit-to-Dig forms

- Daily inspection logs

- Incident records

- Worker training records

Documentation supports compliance and legal defense.

Post-Excavation Reporting

After excavation:

- Utilities must be re-evaluated

- Update maps if new findings arise

- Report unknown utilities encountered

- Submit updated records to authorities

Construction contributes to improving utility databases.

Conclusion

Excavation safety depends heavily on knowing exactly what is beneath the surface. Underground utilities pose hidden dangers that can result in severe injuries, catastrophic accidents, and widespread service disruption. With proper identification, scanning, documentation, marking, verification, and adherence to safe digging procedures, excavation work can proceed with far lower risk and much higher confidence.

Safe excavation begins with smart detection.

For checklist and templates visit The HSE Tools.

Daily Excavation Safety Checklist for Supervisors

Permit to Work System in Excavation Activities

Shoring, Sloping and Benching: Protective Systems Explained

Soil Classification and Testing for Excavation Safety

Excavation Hazards and Their Control Measures

FAQs

1. Who is responsible for marking underground utilities?

Typically utility service providers and site engineers coordinate marking.

2. Which tool detects non-metallic pipes?

Ground penetrating radar (GPR).

3. How close can heavy machinery operate to utilities?

Depending on utility type — but typically not closer than 0.5–1 meter.

4. Are utility maps always accurate?

No — that’s why physical verification is essential.

5. What is the safest way to dig near utilities?

Manual digging or vacuum excavation while maintaining clearance.