Confined Space Entry HIRA – Top 10 Deadly Hazards and the Ultimate Safety Guide

📘 Introduction

Working in a confined space is one of the most dangerous activities in industrial and construction environments. A confined space is not just small—it’s potentially lethal. Oxygen deficiency, toxic gases, engulfment, and entrapment make these jobs high-risk and tightly regulated.

This Confined Space Entry HIRA (Hazard Identification and Risk Assessment) serves as a practical guide to identifying, evaluating, and mitigating risks in tanks, silos, tunnels, sewers, and enclosed process vessels.

⚠️ According to OSHA 29 CFR 1910.146, proper implementation of a Confined Space Entry HIRA can reduce fatalities and injuries by over 60%.

🎯 Objective of the HIRA

The goal of this Confined Space Entry HIRA is to identify and control hazards associated with confined space tasks such as cleaning tanks, entering sewers, or inspecting underground vaults. It ensures safety through engineering controls, administrative procedures, and personal protective equipment.

📌 Definition: What is a Confined Space?

A confined space, by OSHA definition, is any space that:

- Is not designed for continuous occupancy,

- Has restricted entry or exit,

- Is large enough for a worker to enter and perform tasks.

Examples: tanks, pits, manholes, boilers, pipelines, silos.

These spaces require a Confined Space Entry HIRA tailored to the exact conditions of each location.

📊 Activity Description

Workers are required to enter confined spaces for cleaning, maintenance, welding, inspection, or repairs. This involves opening the space, testing the atmosphere, ventilating, using PPE, and assigning a standby person.

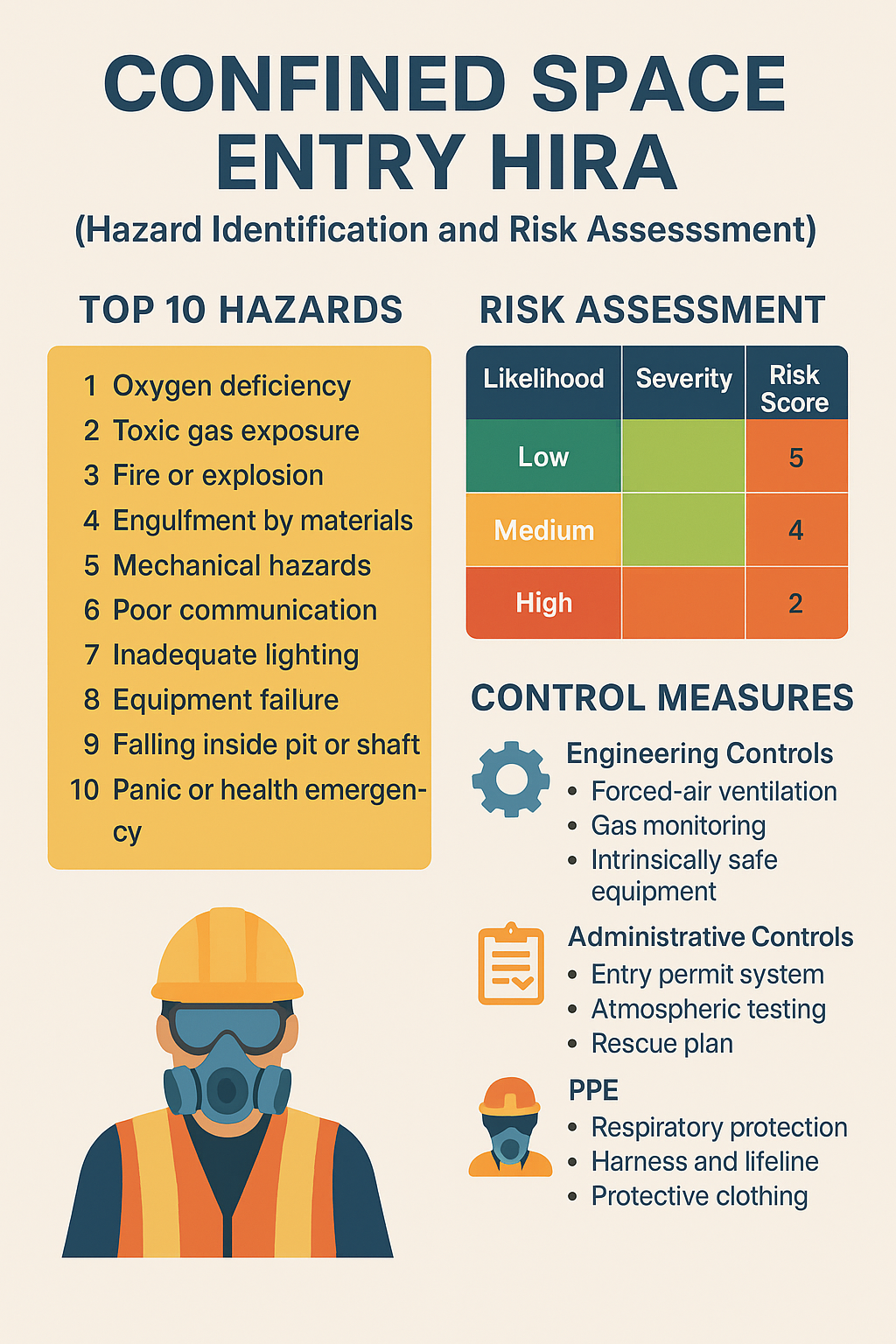

⚠️ Top 10 Hazards in Confined Space Entry

| Hazard | Potential Consequences | Risk Rating | Who’s at Risk |

|---|---|---|---|

| 1. Oxygen deficiency | Asphyxiation, death | Critical | Entrant |

| 2. Toxic gas exposure | Poisoning, death | Critical | Entrant, rescuer |

| 3. Fire or explosion | Burns, fatalities | High | Entire crew |

| 4. Engulfment by materials | Suffocation, trauma | High | Worker inside |

| 5. Mechanical hazards | Crushing, lacerations | High | Entrant |

| 6. Poor communication | Delayed rescue | High | Standby, entrant |

| 7. Inadequate lighting | Trips, missteps | Medium | Entrant |

| 8. Equipment failure (blower, gas detector) | Atmosphere risk | High | All |

| 9. Falling inside pit or shaft | Serious injury | High | Entrant |

| 10. Panic or health emergency | Delayed evacuation | High | Entrant |

Each hazard in the above table must be addressed in your specific Confined Space Entry HIRA.

🔎 Risk Assessment Matrix (Likelihood × Severity)

| Hazard | Likelihood (L) | Severity (S) | Risk Score | Risk Level |

|---|---|---|---|---|

| Oxygen deficiency | 3 | 5 | 15 | High |

| Toxic gas | 4 | 5 | 20 | Critical |

| Engulfment | 3 | 4 | 12 | High |

| Fire hazard | 2 | 5 | 10 | High |

| Mechanical injury | 3 | 3 | 9 | Medium |

Always use this matrix as part of your Confined Space Entry HIRA to prioritize hazards based on their risk levels.

🛠️ Control Measures

🔹 Engineering Controls

- Install forced-air ventilation with continuous monitoring.

- Use intrinsically safe lighting and tools to prevent sparks.

- Equip spaces with oxygen/gas detectors calibrated daily.

- Lockout/Tagout (LOTO) of all energized equipment.

- Provide tripods, retrieval systems, and winches for vertical entries.

🔸 Administrative Controls

- Issue Confined Space Entry Permits for each entry.

- Assign competent roles: entrant, attendant (standby), entry supervisor.

- Develop a rescue plan with practice drills.

- Conduct pre-entry and continuous atmospheric testing.

- Ensure entry authorization and permit sign-off from the supervisor.

- Display entry signage and barricades to restrict access.

👷 PPE Requirements

- SCBA or airline respirators where oxygen is <19.5%

- Full body harness with lifeline

- Flame-resistant coveralls

- Gloves suitable for chemical/mechanical hazards

- Hard hat, goggles, and hearing protection

📋 Safe Work Procedure (SWP)

✅ Before Entry

- Conduct atmospheric testing for O₂, CO, H₂S, and LEL levels.

- Complete a pre-entry checklist and obtain an entry permit.

- Lock out all mechanical or electrical energy sources.

- Assign and brief team roles with emergency protocols.

- Set up communication tools (wired intercom or radio).

- Secure ventilation and lighting equipment.

✅ During Entry

- Continuously monitor atmosphere and PPE status.

- Maintain verbal or radio contact with the entrant.

- Stop work immediately if alarms trigger or communication is lost.

- Prohibit use of electrical or heat-producing devices without hot work permits.

✅ After Exit

- Confirm safe exit and account for all tools and workers.

- Close the permit and debrief the crew.

- Inspect equipment and record entry logs.

👥 Roles and Responsibilities

| Role | Responsibility |

|---|---|

| Entry Supervisor | Authorize permit, ensure controls |

| Attendant | Remain outside, monitor entrant, raise alarm |

| Entrant | Follow instructions, use PPE, stay alert |

| Rescue Team | Respond to emergencies, conduct practice |

| Safety Officer | Audit procedures, review risk assessments |

🆘 Emergency Preparedness

- Keep a rescue tripod and retrieval system on standby.

- Train rescue teams in non-entry and entry rescue techniques.

- Provide CPR-certified first aiders nearby.

- Keep emergency contact numbers visible at the site.

- Store backup SCBA and gas monitors at the entry point.

🧯 Note: Over 60% of confined space fatalities occur among untrained would-be rescuers. Never enter without full protection and a rescue plan.

📊 Monitoring and Audit

- Daily calibration of gas detectors.

- Inspection of harnesses, retrieval gear, and PPE.

- Monthly mock rescue drills.

- Supervisor audit of entry permits.

- Annual confined space safety training certification.

✅ Conclusion

Confined space entry is a high-risk operation where there is no room for error. Without a proper Confined Space Entry HIRA, even a routine inspection can turn fatal. Implementing strict hazard control measures, rescue readiness, and competency training will save lives.

Whether it’s a tank, manhole, or vault, always remember: Test – Ventilate – Protect – Monitor – Rescue.

Top 10 Critical Hazards in Lifting and Rigging Operations HIRA – Ultimate Safety Guide

Equipment Installation and Commissioning HIRA (Hazard Identification and Risk Assessment)

Shuttering and De-shuttering Work HIRA (Hazard Identification and Risk Assessment)

Road Cutting and Paving HIRA (Hazard Identification and Risk Assessment)

Site Housekeeping Activities HIRA (Hazard Identification and Risk Assessment)