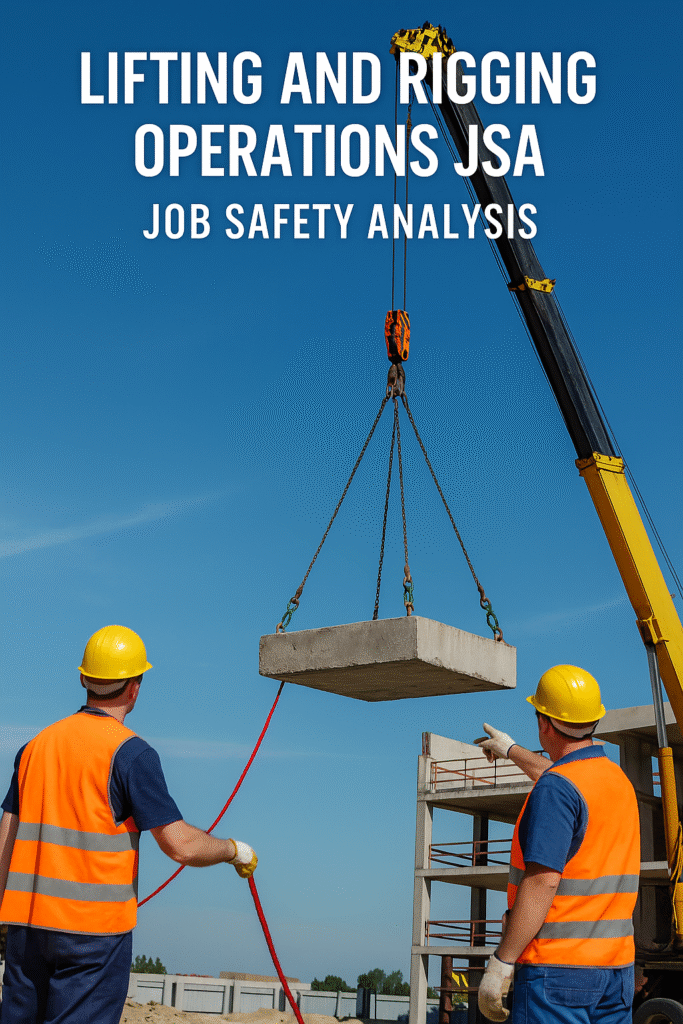

Lifting and Rigging Operations JSA – Job Safety Analysis

1. Introduction

Lifting and rigging operations involve the use of cranes, hoists, forklifts, chain blocks, slings, and rigging hardware to move heavy loads. These tasks are routine in construction, manufacturing, shipping yards, oil & gas, and power plants.

However, lifting and rigging are classified as high-risk activities due to hazards such as:

- Dropped loads

- Overloading equipment

- Rigging failure

- Crane collapse

- Struck-by incidents

- Pinch points and entanglement

- Electrocution from overhead power lines

Improper lifting operations have caused major accidents worldwide. Conducting a Job Safety Analysis (JSA) ensures hazards are identified, risks evaluated, and controls established to prevent accidents.

2. Purpose of This JSA

The objectives are to:

- Prevent accidents during lifting and rigging.

- Ensure all lifting activities are conducted safely and efficiently.

- Protect workers, equipment, and materials.

- Comply with OSHA, ISO, and ASME lifting safety standards.

- Standardize procedures for rigging inspections and lifting operations.

3. Applicable Standards & References

- OSHA 29 CFR 1926.753 – Hoisting and Rigging

- OSHA 29 CFR 1910.184 – Slings

- ASME B30 series – Safety Standards for Cranes, Hoists, Slings, and Rigging

- ISO 12480 – Cranes – Safe Use

- LOLER (UK Regulations) – Lifting Operations and Lifting Equipment Regulations

- Company Lifting Safety Procedure

4. Scope of Work

This JSA applies to:

- Mobile crane operations

- Tower crane lifting

- Forklift and Hydra operations

- Hoist and chain block use

- Rigging with slings, shackles, hooks, spreader beams

- Load movement and placement

- Lifting in confined areas

5. Step-by-Step JSA Process

Step 1: Job Breakdown

- Pre-job planning and risk assessment.

- Obtaining lifting permit and load chart.

- Inspection of lifting equipment and rigging gear.

- Establishing exclusion zones and barricades.

- Attaching slings and securing load.

- Conducting test lift.

- Executing lifting operation (hoisting, slewing, traveling).

- Placing and securing load.

- Post-lift inspection and demobilization.

Step 2: Hazard Identification

- Falling loads – from sling failure or improper rigging.

- Crane overturning – due to overloading or unstable ground.

- Struck-by incidents – workers hit by swinging loads.

- Pinch points – hands/fingers caught during rigging.

- Electrocution – crane boom contacting overhead lines.

- Poor communication – misinterpreted signals causing unsafe movements.

- Mechanical failure – of hooks, shackles, or slings.

Step 3: Risk Assessment Table

| Task | Hazard | Consequence | Risk Rating | Control Measures |

|---|---|---|---|---|

| Pre-job planning | No lifting plan | Collapse, injury | High | Prepare lifting plan, toolbox talk |

| Equipment inspection | Faulty slings, hooks | Load drop | High | Visual & certification check |

| Load rigging | Pinch points | Finger crush | Medium | Use tag lines, gloves |

| Test lift | Overload | Crane tip-over | High | Verify load chart & SWL |

| Hoisting load | Swinging load | Struck-by | High | Exclusion zone, tag lines |

| Slewing load | Overhead power lines | Electrocution | High | Maintain clearance (10 ft min) |

| Load placement | Instability | Collapse, injury | High | Level ground, slow lowering |

6. Control Measures

A. Engineering Controls

- Use cranes and rigging certified for load capacity.

- Install load indicators and limit switches.

- Place outriggers and mats for stability.

- Use spreader beams for long or heavy loads.

B. Administrative Controls

- Implement a Permit-to-Lift System.

- Assign a competent lifting supervisor.

- Conduct a pre-lift meeting/toolbox talk.

- Establish hand signal and radio communication protocols.

- Set up barricades and exclusion zones.

C. PPE Requirements

- Hard hat with chin strap.

- High-visibility vest.

- Steel-toe boots.

- Cut-resistant gloves.

- Safety goggles.

- Fall protection harness (if working at height).

7. Roles & Responsibilities

- Site Manager: Approves lifting plan, provides resources.

- Lifting Supervisor: Manages operations, ensures compliance.

- Rigger: Secures load with slings and hardware.

- Signalman: Guides crane operator with standard signals.

- Crane Operator: Operates equipment safely per instructions.

- Safety Officer: Audits compliance, ensures exclusion zones.

8. Emergency Preparedness

- Rescue plan in case of load collapse or entrapment.

- First aid kits and trained personnel on site.

- Emergency contact numbers displayed.

- Fire extinguishers nearby (for hydraulic/electrical fires).

- Clear evacuation routes.

9. Best Practices for Lifting and Rigging Safety

- Always check Safe Working Load (SWL) and never exceed it.

- Inspect slings, hooks, and shackles before use.

- Keep workers clear of suspended loads.

- Use tag lines to control load swing.

- Never stand under suspended loads.

- Maintain minimum clearance of 10 feet from power lines.

- Stop lifting during high winds or poor visibility.

- Store rigging equipment properly after use.

10. Sample JSA Form – Lifting & Rigging Operations

Job Title: Lifting and Rigging Operations

Location: ____________________

Date: ____________________

Supervisor: ____________________

| Task Step | Hazard | Control Measure | PPE Required | Responsible Person |

|---|---|---|---|---|

| Pre-lift planning | Lack of lifting plan | Permit-to-lift system | Helmet, vest | Supervisor |

| Equipment inspection | Faulty rigging gear | Visual & certification checks | Gloves, boots | Rigger |

| Attaching load | Pinch points | Tag lines, gloves | Gloves | Rigger |

| Test lift | Overload | SWL check | Helmet | Operator |

| Hoisting | Swinging load | Exclusion zone, signaler | Vest, helmet | Operator |

| Load placement | Collapse | Level ground | Gloves, boots | Supervisor |

11. Conclusion

Lifting and rigging operations are high-risk but essential for construction and industrial work. The success of safe lifting depends on proper planning, certified equipment, skilled personnel, clear communication, and strict adherence to procedures.

✅ Final Safety Reminder:

“Every lift has a risk — plan it, control it, and execute it safely.”

Hot Work JSA – Job Safety Analysis

Rebar Cutting and Bending JSA – Job Safety Analysis

Concrete Pouring and Formwork JSA – Job Safety Analysis

Excavation and Trenching Safety JSA – Job Safety Analysis

Scaffold Erection and Dismantling JSA – Job Safety Analysis