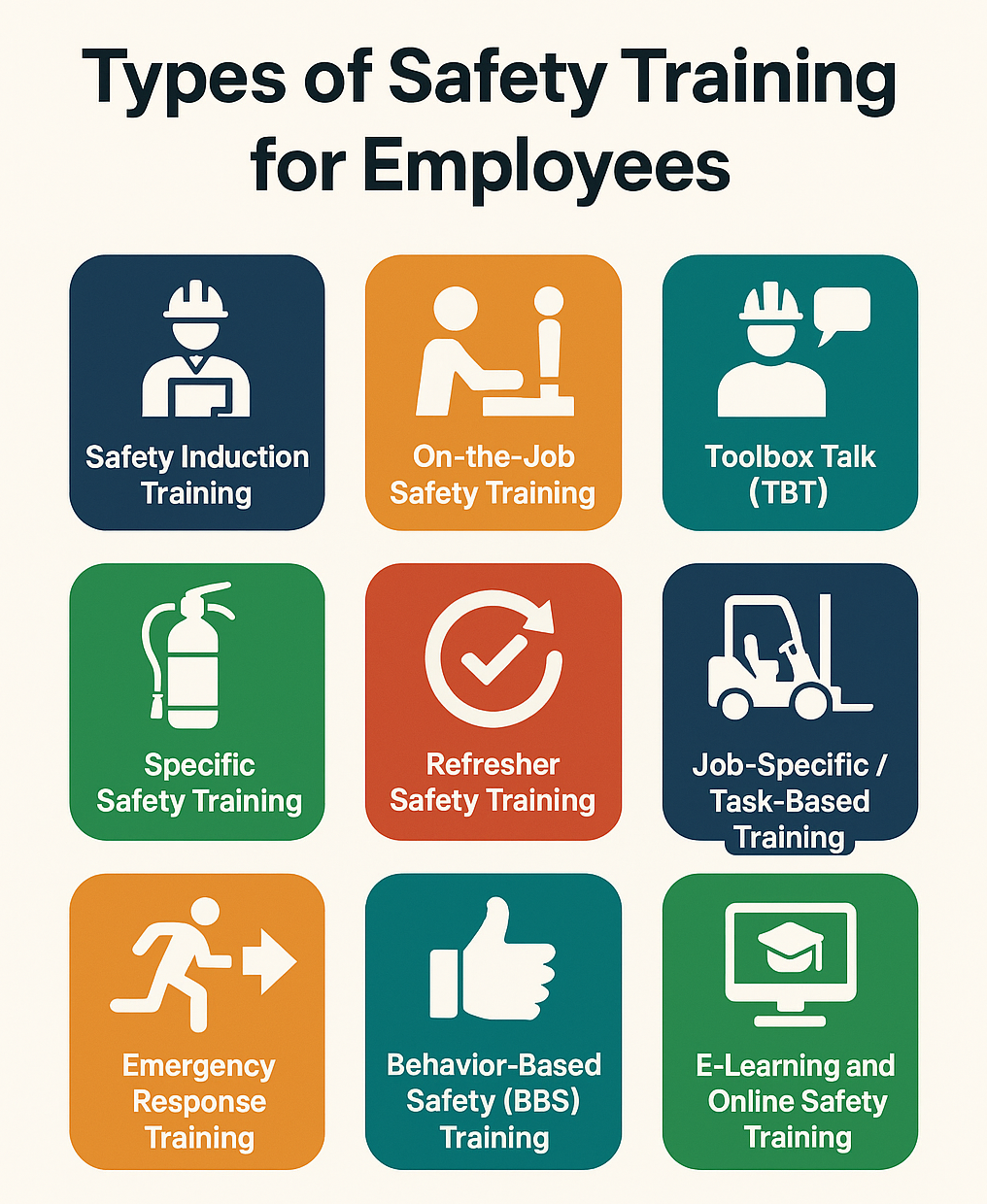

Types of Safety Training for Employees

Every workplace—whether it’s a construction site, an oil refinery, a factory, or even a corporate office—comes with its share of risks. The best way to manage these risks isn’t just through equipment or policies but by preparing employees with effective safety training. Training ensures that workers are not only aware of potential hazards but also equipped with the skills to avoid, control, or respond to them.

In this article, we’ll explore the different types of safety training for employees—from induction sessions to task-specific programs—and explain how each contributes to a safer and more productive workplace.

1. Safety Induction Training

Safety induction is the first stage of safety awareness for new employees, contractors, or visitors entering a workplace.

- Purpose: To introduce company rules, emergency procedures, and site-specific hazards.

- Topics Covered: PPE requirements, reporting accidents, evacuation routes, first aid stations, restricted areas.

- Example: A new hire at a manufacturing plant attends a one-day induction where they learn about machinery zones, chemical storage rules, and fire exits.

👉 Without induction training, new workers often feel lost and are more prone to mistakes that could lead to accidents.

2. On-the-Job Safety Training

This training happens while employees are performing their actual tasks. It’s hands-on, practical, and guided by supervisors or senior workers.

- Benefits:

- Immediate application of safety knowledge.

- Builds confidence with real equipment.

- Encourages peer-to-peer learning.

- Example: A welder learns proper fire watch procedures while doing supervised welding, or a forklift driver practices safe reversing under guidance.

On-the-job training is one of the most effective methods because it merges theory with practice.

3. Toolbox Talk (TBT) Training

Toolbox Talks (TBTs) are short, focused discussions on safety topics, usually held at the start of the workday.

- Duration: 5–15 minutes.

- Common Topics:

- Excavation hazards

- Work at height safety

- Electrical shock prevention

- Housekeeping on site

- Benefits:

- Keeps safety “fresh” in workers’ minds.

- Provides an opportunity to address current site risks.

- Encourages interaction and feedback.

Example: Before beginning scaffold erection, a supervisor gives a TBT on harness use, fall arrest systems, and wind conditions.

Think of TBTs as “daily safety reminders” that sharpen worker awareness before tasks.

4. Specific Safety Training

Certain jobs and industries demand specialized training programs because the risks are higher.

- Fire Safety Training – how to use extinguishers, fire drills, and evacuation steps.

- First Aid Training – CPR, bleeding control, fracture support.

- Chemical Handling Training – reading Safety Data Sheets (SDS), spill control, and PPE.

- Working at Height Training – scaffolding, ladders, and lifeline systems.

- Confined Space Entry Training – entry permits, air monitoring, and emergency rescue plans.

👉 Example: In the oil and gas industry, workers receive Hydrogen Sulfide (H₂S) Training to recognize gas leaks and use self-rescue respirators.

5. Refresher Safety Training

Safety knowledge fades over time, so refresher courses are vital to keep employees updated.

- Frequency: Usually conducted annually or biannually.

- Focus Areas: Lessons learned from recent incidents, updated legal requirements, and reminders of best practices.

- Example: A company organizes a refresher session on emergency evacuation after a mock drill reveals weaknesses in employee response.

Regular refreshers help employees avoid complacency.

6. Job-Specific / Task-Based Training

These are highly focused training sessions for employees performing specialized roles.

- Forklift Training – safe driving, load handling, pedestrian safety.

- Crane and Rigging Training – load stability, lifting signals, exclusion zones.

- Hot Work Training – fire watch duties, spark containment, PPE.

Example: A refinery requires welders to undergo hot work permit training before being authorized to weld inside hazardous zones.

7. Emergency Response Training

Emergencies strike without warning. Employees must know how to react quickly and calmly.

- Mock Drills: fire evacuation, chemical spill containment, earthquake drills.

- Rescue Plans: confined space rescues, man-down procedures.

- Mutual Aid Groups (MARGs): industries collaborating with local authorities during major accidents.

Case Example: A pharmaceutical company conducts a mock drill for chemical spills, teaching employees how to neutralize the spill, evacuate safely, and inform emergency teams.

8. Behavior-Based Safety (BBS) Training

BBS training focuses on human behavior and decision-making.

- Encourages safe behavior through observation and feedback.

- Identifies and corrects unsafe habits.

- Promotes a culture of accountability.

Example: A construction company tracks near-miss reports and uses them in BBS training to coach workers on safer behaviors.

9. E-Learning and Online Safety Training

Modern workplaces are adopting digital learning platforms.

- Advantages: accessible anytime, cost-effective, consistent delivery.

- Examples: interactive modules, VR simulations, safety quizzes.

- Limitation: cannot fully replace hands-on demonstrations.

For office employees, online training works well for topics like cybersecurity, ergonomics, and fire awareness.

10. Contractor Safety Training

Contractors and temporary workers face equal or greater risks compared to permanent staff.

- Why it’s important: contractors may be unfamiliar with site rules.

- Covers: site-specific induction, permit-to-work systems, restricted zones.

- Example: Before entering a chemical plant, contractors must complete safety orientation and PPE training.

11. Supervisor and Manager Safety Training

Safety leadership starts at the top. Managers and supervisors require additional training on:

- Conducting risk assessments.

- Leading incident investigations.

- Motivating teams to follow safety protocols.

Example: A site manager undergoes training in Root Cause Analysis (RCA) to handle workplace accidents effectively.

12. Continuous Safety Awareness Programs

Safety isn’t a one-time lesson. Companies keep awareness alive with:

- Safety Weeks and campaigns.

- Posters and digital reminders.

- Competitions and reward systems for safe practices.

These programs complement formal training and create a “safety-first mindset.”

Comparison of Different Types of Safety Training for Employees

| Type of Training | When It’s Conducted | Purpose | Key Features | Examples |

|---|---|---|---|---|

| Safety Induction Training | At the time of joining (first day or week) | Introduce employees to workplace hazards, policies, and emergency procedures | Covers company rules, PPE use, site orientation, reporting procedures | New hire orientation at a construction site |

| On-the-Job Safety Training | During actual job tasks under supervision | Teach safe work methods in real conditions | Practical, hands-on, task-specific | Welder trained in safe cutting techniques; forklift operator under supervision |

| Toolbox Talk (TBT) | Daily or weekly, usually before work begins | Provide short, focused reminders about specific hazards | 5–15 min sessions, interactive, hazard-based | TBT on fall protection before scaffold work |

| Specific Safety Training | As required, depending on job risk | Provide in-depth knowledge of high-risk activities | Specialized (fire, first aid, chemical handling, confined space) | Fire extinguisher use, confined space entry permit training |

| Refresher Training | Annually or biannually | Reinforce knowledge and update employees on new risks | Reviews incidents, regulations, and procedures | Yearly evacuation drill or PPE refresher |

| Job-Specific / Task-Based Training | Before taking up specialized roles | Ensure workers are competent for specific jobs | Focus on equipment or task safety | Forklift license training, crane operator training |

| Emergency Response Training | Periodically (mock drills, quarterly or yearly) | Prepare employees for crisis situations | Evacuation drills, rescue techniques, mutual aid | Fire drill, chemical spill response |

| Contractor Safety Training | Before contractors start work | Ensure contractors follow site rules | Induction, permit-to-work, restricted zones | Contractors briefed before entering chemical plant |

| Supervisor/Manager Training | When promoted or hired into leadership | Equip leaders with safety leadership skills | Risk assessment, RCA, leadership in safety | Manager trained in incident investigation |

13. Best Practices for Conducting Safety Training

- Keep sessions interactive (videos, role plays, Q&A).

- Use real accident case studies to reinforce learning.

- Provide training in local languages for better understanding.

- Regularly evaluate training effectiveness through audits and mock drills.

Conclusion

Safety training is not just about compliance—it’s about saving lives, preventing injuries, and creating a confident, productive workforce. From induction sessions for new employees to specialized training for high-risk jobs, every type plays a role in protecting workers. The best workplaces don’t treat safety as a checkbox—they build it as a culture.

When employees are well-trained, they don’t just follow safety—they live it.

Types of Safety Training for Employees

Safety Induction Training for Employees

50 Workplace Safety Topics for Meetings

How to Conduct a Safety Induction for New Workers (With Script)

FAQs

1. What is the most important type of safety training?

Safety induction is crucial because it lays the foundation for all future training.

2. How often should refresher training be done?

At least once a year, though high-risk industries may require quarterly sessions.

3. Why are Toolbox Talks important?

They provide quick, daily reminders that keep safety top-of-mind.

4. Do contractors need the same training as employees?

Yes, contractors must receive site-specific training before starting work.

5. Can online training replace in-person training?

No, online training is excellent for theory but must be combined with practical demonstrations.