Crane, Lifting & Rigging Safety Training

Cranes, lifting equipment, and rigging systems are essential for modern industry. From construction and oil refineries to shipyards and power plants, lifting heavy loads safely is critical. But with this power comes serious risks—falls, dropped loads, crane collapses, and rigging failures often lead to fatal accidents.

Proper Crane, Lifting & Rigging Safety Training ensures that operators, riggers, and supervisors understand hazards, legal requirements, safe practices, and emergency responses. This guide explores step-by-step safety procedures, OSHA standards, and best practices to protect workers and equipment.

Hazards in Crane, Lifting & Rigging Operations

1. Crane Hazards

- Overturning due to improper ground conditions

- Boom collapse from overloading

- Contact with overhead power lines

- Poor visibility during lifting

2. Rigging Hazards

- Wrong sling selection

- Damaged ropes, chains, or hooks

- Improper angle of slings

- Shock loading causing equipment failure

3. Load Handling Hazards

- Dropped loads hitting workers below

- Swinging or rotating loads

- Load shifting due to improper balance

💡 Example: In 2022, a tower crane collapse in India killed multiple workers. Investigation revealed lack of proper inspection and overloaded lifting as root causes.

OSHA & International Standards

- OSHA 29 CFR 1926 Subpart CC – Cranes & Derricks in Construction

- OSHA 29 CFR 1910.184 – Slings

- ANSI/ASME B30 – Crane & Rigging Safety Standards

- ISO 9927 – Crane Inspections

- ILO Safety Conventions – Worker safety in lifting operations

👉 Employers must ensure certified crane operators and trained riggers are on site.

Types of Cranes & Rigging Equipment

Types of Cranes

- Tower cranes

- Mobile cranes (hydraulic, rough terrain)

- Overhead bridge cranes

- Gantry cranes

Rigging Equipment

- Wire rope slings

- Chain slings

- Synthetic web slings

- Shackles, hooks, and turnbuckles

- Spreaders and lifting beams

Key Elements of Crane, Lifting & Rigging Safety Training

1. Pre-Lift Planning

- Risk assessment & JSA

- Weight calculation and load charts

- Crane selection and ground stability checks

2. Permit-to-Work System

- Work permits for critical lifts

- Hot work permits if lifting near flammable zones

3. Inspections

- Daily crane operator checklist

- Rigging gear inspection before use

- Third-party periodic certification

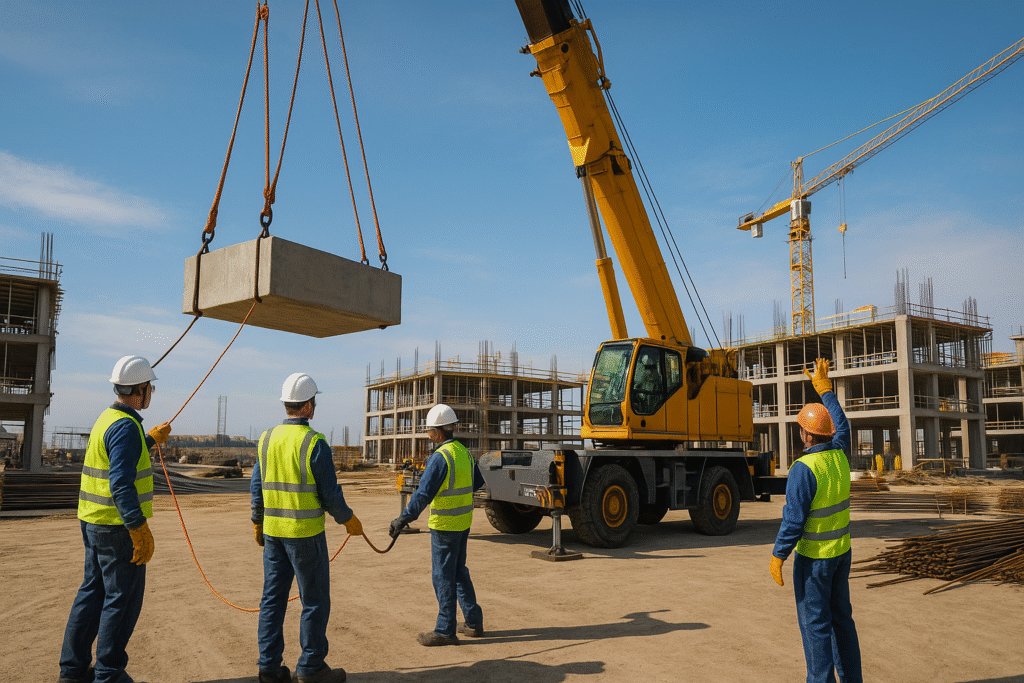

4. Safe Rigging Practices

- Use proper sling angles (avoid sharp bends)

- Never exceed Working Load Limit (WLL)

- Protect slings from sharp edges with padding

- Tagline use to control swinging loads

5. Load Handling

- Lift slowly to avoid shock loading

- Never pass load over workers

- Maintain clear communication signals

- Keep unauthorized persons out of lifting zone

6. PPE Requirements

- Hard hats, gloves, steel-toe boots

- High-visibility vests

- Fall protection when working at heights

Roles & Responsibilities

- Crane Operator: Only certified operators, follow load charts, perform pre-use checks

- Rigger: Selects rigging gear, attaches loads, gives signals

- Signal Person: Maintains clear communication with operator

- Supervisor: Approves critical lifts, ensures safety procedures

- Safety Officer: Conducts inspections, enforces safety rules

Step-by-Step Safe Lifting Procedure

- Plan the Lift – Calculate load, select equipment, and check weather

- Inspect Equipment – Crane, rigging gear, and lifting accessories

- Set Up Crane – Level ground, outriggers deployed

- Rig the Load – Choose correct slings, secure with shackles/hooks

- Pre-Lift Meeting – Roles, communication signals, and emergency plan

- Test Lift – Slowly raise load a few inches to confirm stability

- Execute Lift – Lift steadily, maintain control, avoid sudden movements

- Lower Safely – Place load gently, remove rigging gear carefully

- Close Permit – Supervisor signs off after completion

Emergency Situations & Response

- Crane Collapse: Evacuate area, shut off power, contact emergency services

- Dropped Load: Secure zone, first aid for injured workers

- Power Line Contact: Operator remains inside cab until power is cut

- Rigging Failure: Stop work, quarantine defective equipment

Real-World Case Studies

- New York Crane Collapse (2008): 7 workers killed due to faulty rigging.

- Dubai Mobile Crane Accident (2019): Crane toppled due to improper outriggers.

- Indian Port Accident (2020): Gantry crane collapse killed 11 workers during testing.

👉 All highlight the importance of training, inspection, and supervision.

Best Practices in Crane, Lifting & Rigging Safety

- Use taglines to guide loads

- Conduct mock lift drills for critical lifts

- Apply color coding for slings and shackles

- Use load indicators and anti-two-block devices

- Maintain lifting operation logbooks

Training Program Structure

Module 1: Introduction to Crane Safety

Module 2: Crane Types & Capabilities

Module 3: Rigging Equipment & Inspections

Module 4: Load Calculations & Charts

Module 5: Communication & Signals

Module 6: Safe Operating Practices

Module 7: Emergency Response Procedures

Module 8: Case Studies & Lessons Learned

👉 Duration: 3–5 days (theory + hands-on)

Training Checklists & Templates

Crane Daily Checklist:

- Tires/tracks condition

- Brakes, steering, controls

- Wire ropes, hooks, safety latches

- Outriggers deployed

Rigging Gear Checklist:

- No frayed wires or chains

- Hooks with safety latch

- Identification tags intact

- WLL visible

FAQs – Crane, Lifting & Rigging Safety

Q1. Who can operate a crane?

👉 Only trained, certified, and authorized operators.

Q2. What is a critical lift?

👉 Any lift that exceeds 75% of crane capacity or involves unusual risk.

Q3. How often should rigging gear be inspected?

👉 Before each use and periodically by a competent person.

Conclusion

Crane, lifting, and rigging operations require absolute precision and strict safety protocols. Proper training ensures that workers understand hazards, equipment limitations, rigging practices, and emergency response.

When operators, riggers, and supervisors follow standard procedures and continuous training, industries can prevent costly accidents and save lives.

Remember: Every lift is critical—treat it with respect.

Confined Space Entry Procedures Safety Training

Safety Training Topics for Construction Workers

15 EHS Training Topics for a Safer Workplace

Monthly Safety Training Topics