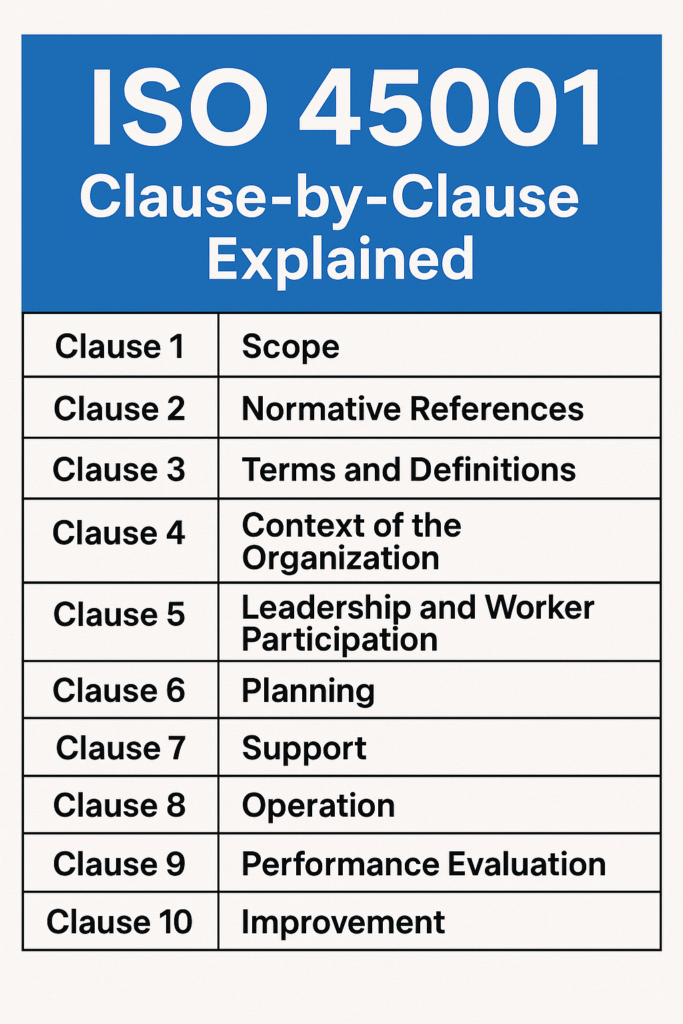

ISO 45001 Clauses Explained: Complete Guide

Introduction

Occupational health and safety (OHS) is a major challenge across industries. According to the International Labour Organization (ILO), millions of workplace accidents occur annually, leading to human suffering and huge economic losses. Organizations need a structured and internationally recognized approach to ensure worker protection.

ISO 45001:2018 is the world’s first global standard for Occupational Health and Safety Management Systems (OHSMS). It was developed to replace OHSAS 18001 and align with the Annex SL framework used in other ISO standards (like ISO 9001 and ISO 14001).

This article will explain all ISO 45001 clauses (1–10) in detail so you understand exactly what the standard requires.

📌 ISO 45001 Clauses (1–10)

Clause 1: Scope

The standard’s scope defines what ISO 45001 covers.

- It applies to any organization, regardless of size, type, or industry.

- The main purpose is to prevent work-related injuries, illnesses, and fatalities.

- It also aims to improve OHS performance continually.

- The standard is applicable to all activities, whether routine or non-routine, permanent or temporary, on-site or off-site.

💡 Example: A construction company, a hospital, and a small office—all can apply ISO 45001.

Clause 2: Normative References

ISO 45001 does not rely on other specific standards as normative references.

- This means it is self-contained.

- Organizations don’t need to purchase additional documents to implement it.

Clause 3: Terms and Definitions

This clause provides clear definitions to avoid misinterpretation. Some key terms include:

- Worker – Anyone performing work under the control of the organization (employees, contractors, interns).

- Hazard – Source or situation with the potential to cause injury or ill health.

- Risk – Combination of likelihood and severity of harm.

- Incident – Occurrence arising out of or in connection with work, which could have caused harm (includes near misses).

- Continual Improvement – Ongoing efforts to enhance OHSMS performance.

💡 Example: If a worker slips on a wet floor but isn’t injured, it’s still an incident (near miss).

Clause 4: Context of the Organization

Organizations must understand their environment and stakeholders before implementing OHSMS.

Requirements:

- Identify internal issues – workforce skills, culture, resources.

- Identify external issues – regulations, clients, unions, industry trends.

- Understand needs/expectations of stakeholders – workers, regulators, customers, suppliers.

- Define scope of OHSMS – Decide which sites, activities, or processes are included.

💡 Example: A chemical factory considers both internal risks (chemical handling) and external risks (legal requirements, community expectations).

Clause 5: Leadership and Worker Participation

Top management plays a critical role in ensuring success.

Requirements:

- OHS Policy – Establish and communicate a clear safety policy.

- Roles & Responsibilities – Assign authority and accountability.

- Leadership Commitment – Provide resources, lead by example.

- Worker Participation – Engage workers in risk assessments, incident reporting, audits.

- Consultation – Encourage open communication without fear of reprisal.

💡 Example: A company introduces “safety suggestion boxes” and rewards employees for reporting hazards.

Clause 6: Planning

Planning ensures risks are identified and managed proactively.

Requirements:

- Hazard Identification – Systematically find hazards (physical, chemical, ergonomic, psychosocial).

- Risk Assessment – Analyze risks using tools like a 5×5 risk matrix.

- Opportunities – Identify ways to improve safety culture and performance.

- Legal & Regulatory Compliance – List applicable laws (e.g., OSHA, HSE).

- Objectives & Programs – Define measurable goals (e.g., reduce LTIFR by 20% in 12 months).

💡 Example: A warehouse identifies hazards like forklift collisions, poor lighting, and noise.

Clause 7: Support

An OHSMS can only succeed with adequate resources and support systems.

Requirements:

- Resources – Provide funding, PPE, safety officers, and technology.

- Competence – Train workers and verify their skills.

- Awareness – Ensure workers know hazards and procedures.

- Communication – Internal (toolbox talks, posters) and external (clients, regulators).

- Documented Information – Policies, manuals, SOPs, risk registers.

💡 Example: A hospital trains staff on handling infectious diseases and documents all protocols.

Clause 8: Operation

This clause focuses on executing safety practices.

Requirements:

- Operational Control – Establish SOPs for high-risk activities.

- Hierarchy of Controls – Eliminate → Substitute → Engineer → Administrative → PPE.

- Management of Change – Assess risks before introducing new processes.

- Procurement – Ensure suppliers and contractors follow safety standards.

- Emergency Preparedness & Response – Fire drills, evacuation plans, first-aid systems.

💡 Example: A refinery conducts mock fire drills every quarter and trains workers on spill response.

Clause 9: Performance Evaluation

Organizations must measure and evaluate safety performance.

Requirements:

- Monitoring & Measurement – Track leading (training hours, inspections) and lagging indicators (accidents, lost days).

- Internal Audit – Conduct audits to verify OHSMS effectiveness.

- Management Review – Top management reviews OHS performance periodically.

💡 Example: A logistics company monitors near-miss reports and accident frequency rate monthly.

Clause 10: Improvement

Continuous improvement ensures long-term effectiveness.

Requirements:

- Incident Investigation – Identify root causes and take action.

- Corrective Action – Eliminate nonconformities to prevent recurrence.

- Continual Improvement – Constantly seek safer processes, better equipment, and improved training.

💡 Example: After a scaffolding accident, a construction firm updates training and invests in safer scaffolding systems.

Key Benefits of ISO 45001

- ✅ Reduces workplace accidents and illnesses.

- ✅ Ensures compliance with laws and standards.

- ✅ Improves employee morale and retention.

- ✅ Enhances brand reputation and trust.

- ✅ Provides competitive advantage in contracts.

- ✅ Saves costs through reduced downtime and claims.

Implementation Roadmap

- Conduct gap analysis.

- Develop OHS policy & objectives.

- Train employees and managers.

- Identify hazards & assess risks.

- Document procedures & emergency plans.

- Conduct internal audits.

- Undergo certification audit.

External Link: 👉 ISO 45001 – Occupational Health and Safety Management Systems (International Organization for Standardization)

ISO 31000—Risk Management Basics

ISO 45001 vs OHSAS 18001: What’s the Difference?

ISO 45001:2018 Explained: Key Principles and Core Objectives

ISO 45001:2023 Changes You Should Be Aware Of

FAQs

Q1: Is ISO 45001 mandatory?

No, but many industries require it contractually.

Q2: How long does certification take?

6–12 months depending on organization size.

Q3: Who certifies ISO 45001?

Accredited certification bodies like BSI, TÜV, SGS, DNV.

Q4: Can ISO 45001 integrate with other ISO standards?

Yes, it aligns with ISO 9001 (Quality) and ISO 14001 (Environment).