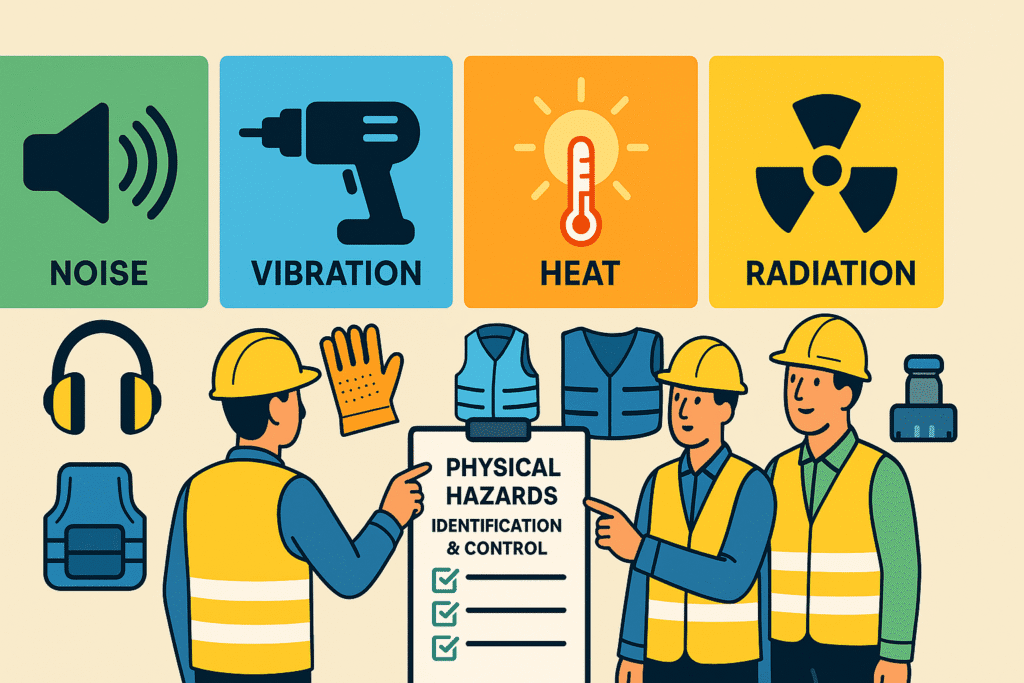

Physical Hazards at Work (Noise, Vibration, Heat, Radiation): Identification & Control

Physical hazards are some of the most common risks faced by workers across industries. Unlike chemical or biological hazards, physical hazards relate to environmental conditions or physical forces that can harm the body. This guide explains the major types of physical hazards — noise, vibration, heat, and radiation — and shows how to identify and control them effectively.

1. What Are Physical Hazards?

Physical hazards are environmental factors or energy forms capable of causing injury or illness without necessarily touching a worker. They include noise, vibration, heat, cold, pressure, and radiation. Exposure may be acute (immediate injury) or chronic (long-term illness).

Examples:

- Loud machinery in manufacturing.

- Hand-arm vibration from power tools.

- High ambient temperatures in foundries.

- Ionizing radiation in medical imaging.

2. Noise Hazards

2.1 Definition

Noise is unwanted sound that can damage hearing, interfere with communication, and increase stress levels.

2.2 Health Effects

- Temporary or permanent hearing loss.

- Tinnitus (ringing in the ears).

- Increased fatigue and reduced concentration.

2.3 Identification

- Conduct workplace noise surveys using a sound level meter.

- Identify tasks and areas exceeding permissible exposure limits (e.g., 85 dB(A) for 8 hours per OSHA).

2.4 Control Measures

- Elimination/Substitution: Use quieter processes or machines.

- Engineering Controls: Install acoustic enclosures, barriers, and dampers.

- Administrative Controls: Rotate staff, schedule noisy tasks when fewer workers are present.

- PPE: Provide properly fitted hearing protectors (earplugs/earmuffs).

- Monitoring: Conduct baseline and periodic audiometric testing.

3. Vibration Hazards

3.1 Definition

Vibration hazards arise from exposure to oscillating mechanical motion transmitted to the hands/arms (HAV) or the whole body (WBV).

3.2 Health Effects

- Hand-Arm Vibration Syndrome (HAVS).

- Carpal tunnel syndrome.

- Lower back pain and spinal issues (from WBV).

3.3 Identification

- Measure vibration magnitude using vibration meters.

- Identify tools and vehicles with high vibration exposure.

- Assess exposure duration and frequency.

3.4 Control Measures

- Engineering Controls: Maintain and balance equipment, use vibration dampening handles.

- Substitution: Select low-vibration tools and vehicles.

- Administrative Controls: Limit exposure time, implement job rotation.

- PPE: Use anti-vibration gloves as supplementary protection.

- Training: Educate workers on correct tool use and posture.

4. Heat Hazards

4.1 Definition

Heat hazards occur when workers are exposed to high temperatures, radiant heat, or high humidity, leading to heat stress.

4.2 Health Effects

- Heat rash, cramps, exhaustion, or stroke.

- Dehydration and reduced cognitive performance.

4.3 Identification

- Conduct a heat stress assessment using Wet Bulb Globe Temperature (WBGT) index.

- Identify high-risk areas (boilers, foundries, outdoor summer work).

4.4 Control Measures

- Engineering Controls: Provide ventilation, air conditioning, reflective shields.

- Administrative Controls: Schedule heavy work during cooler hours, implement rest breaks.

- Hydration: Supply cool drinking water and electrolyte replacements.

- PPE: Use cooling vests or reflective clothing.

- Training: Teach early recognition of heat stress symptoms.

5. Radiation Hazards

5.1 Definition

Radiation hazards include ionizing (X-rays, gamma rays) and non-ionizing (UV, infrared, microwave) radiation sources.

5.2 Health Effects

- Ionizing: Cellular damage, cancer risk, acute radiation sickness.

- Non-ionizing: Skin burns, eye damage (UV), tissue heating.

5.3 Identification

- Survey workplaces for radiation sources (medical imaging, industrial radiography, welding arcs, UV curing).

- Use dosimeters or radiation meters to measure exposure.

5.4 Control Measures

- Elimination/Substitution: Use alternative processes not requiring radiation.

- Engineering Controls: Shielding (lead walls, UV filters), interlocks, remote handling.

- Administrative Controls: Limit exposure time, restrict access, rotate staff.

- PPE: Lead aprons, gloves, face shields, UV-blocking goggles.

- Monitoring: Maintain personal dosimetry records and comply with dose limits.

6. Integrating Physical Hazard Control Into Safety Management

- Include noise, vibration, heat, and radiation assessments in routine risk assessments.

- Involve workers in hazard reporting and control selection.

- Maintain equipment and engineering controls.

- Provide regular training and health surveillance.

Learn more from OSHA’s Physical Agents page, which provides standards and exposure limits for noise, vibration, heat, and radiation.

Exam-Oriented Questions with Detailed Answers

Short Answer Questions

Q1. Name four common physical hazards at work.

Answer: Noise, vibration, heat, and radiation.

Q2. What is the permissible noise exposure limit for an 8-hour shift according to OSHA?

Answer: 85 dB(A) (action level).

Q3. List two health effects of exposure to vibration.

Answer: Hand-Arm Vibration Syndrome (HAVS) and lower back pain from whole-body vibration.

Long Answer Questions

Q1. Describe the process of identifying noise hazards in a workplace.

Answer: Conduct a noise survey using sound level meters or dosimeters. Identify areas and tasks exceeding permissible exposure limits. Record duration of exposure for workers. Use results to develop a noise control plan, including engineering, administrative, and PPE measures.

Q2. Explain how heat stress can be prevented using engineering, administrative, and personal controls.

Answer: Engineering controls include installing ventilation, air conditioning, and reflective shields. Administrative controls include scheduling heavy work during cooler times, rotating staff, and providing rest breaks. Personal controls include hydration, cooling vests, and training workers to recognise heat stress symptoms early.

Q3. Discuss the difference between ionizing and non-ionizing radiation hazards and how to control them.

Answer: Ionizing radiation (X-rays, gamma rays) penetrates tissue and can damage cells, requiring shielding (lead, barriers) and dosimetry. Non-ionizing radiation (UV, infrared) causes surface burns and eye damage, controlled by filters, shields, and UV-blocking PPE. Both require limiting exposure time and restricting access.

Scenario-Based Questions

Q1. Workers in a foundry are experiencing heat stress symptoms. Apply a control plan.

Answer: Install ventilation and cooling systems (engineering), schedule heavy work for early morning (administrative), supply cool water and electrolyte drinks, provide light reflective PPE, and train staff to spot heat stress symptoms.

Q2. An employee regularly uses a high-vibration power tool and reports tingling in fingers. What steps should you take?

Answer: Measure tool vibration levels, maintain and replace worn tools, rotate tasks to limit exposure, supply anti-vibration gloves, and arrange medical assessment for Hand-Arm Vibration Syndrome.

Q3. A hospital imaging room uses X-ray machines. How do you protect staff?

Answer: Shield the room with lead walls, provide lead aprons and thyroid shields, restrict access during imaging, rotate staff to reduce exposure, and maintain dosimetry records.

Frequently Asked Questions (FAQs)

1. What are physical hazards in the workplace?

Answer: Environmental factors such as noise, vibration, heat, and radiation that can harm workers without direct contact.

2. How can noise hazards be controlled?

Answer: Through elimination or substitution of noisy processes, installing acoustic enclosures, rotating staff, and providing hearing protection.

3. What is the difference between hand-arm and whole-body vibration?

Answer: Hand-arm vibration is transmitted through the hands and arms from tools, causing HAVS, while whole-body vibration is transmitted through seats or floors, leading to back problems.

4. How is heat stress assessed?

Answer: Using the Wet Bulb Globe Temperature (WBGT) index, which considers temperature, humidity, air movement, and radiant heat.

5. What’s the main control for radiation hazards?

Answer: Shielding combined with limiting exposure time and maintaining safe distances. PPE such as lead aprons supplements these controls.

6. Why is health surveillance important for physical hazards?

Answer: It detects early signs of harm (hearing loss, HAVS, heat exhaustion, radiation dose exceedances) so controls can be improved before serious illness occurs.

7. Conclusion

Physical hazards like noise, vibration, heat, and radiation are present in many workplaces. Identifying them, assessing their risks, and applying controls according to the hierarchy protects workers and ensures compliance. This guide, complete with examples, exam questions, answers, and FAQs, provides a practical resource for safety professionals to manage these hazards effectively.

Hazard Identification, Risk Assessment, and Risk Control (HIRARC)

The Hierarchy of Controls Explained: How to Manage Hazards Effectively

Difference Between Hazard and Risk: A Practical Guide for Safety Professionals