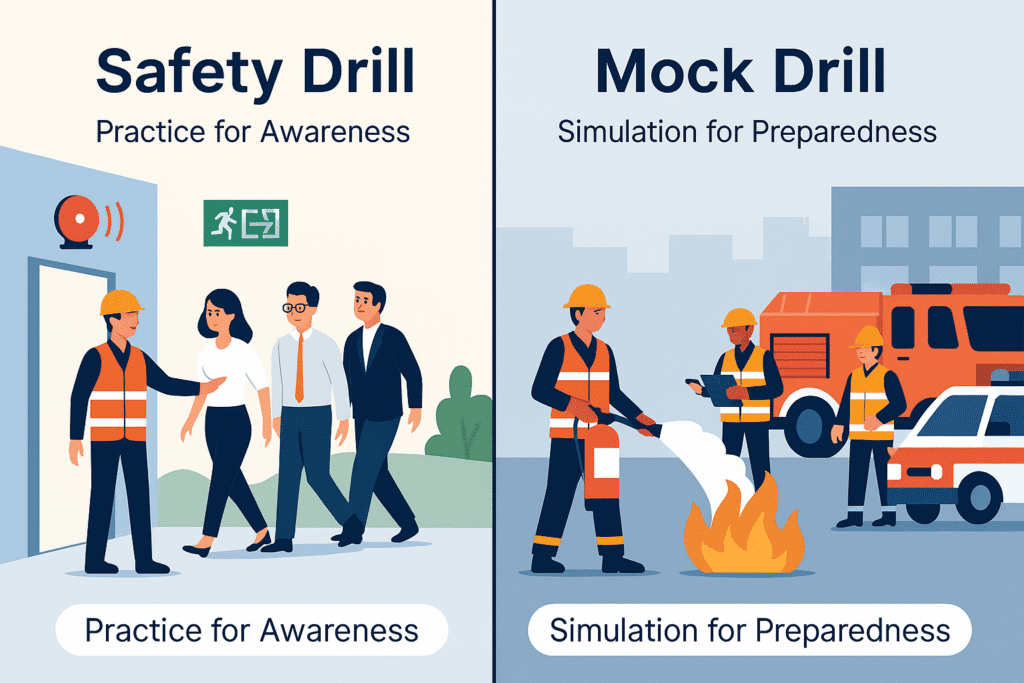

Safety Drill vs Mock Drill

Have you ever wondered what the real difference is between a safety drill and a mock drill?

They sound similar — and both involve practicing emergency procedures — but their purpose, scope, and outcomes are quite different.

In this guide, we’ll break down what each one means, how they’re conducted, and why both are essential for an organization’s emergency preparedness and compliance.

What is a Safety Drill?

Definition

A safety drill is a planned exercise designed to train employees and test how they respond to specific emergency situations such as fire, earthquake, or chemical spills.

Its goal is to educate and prepare individuals to act correctly and calmly when an actual emergency occurs.

Purpose

- To familiarize workers with emergency exits and evacuation routes.

- To ensure everyone knows assembly points and alarm procedures.

- To assess whether safety equipment (fire extinguishers, alarms, PPE) works properly.

- To reinforce the importance of quick, safe responses.

Examples

- Fire evacuation drills.

- Earthquake or flood drills.

- Electrical shock response drills.

- First aid or CPR training drills.

Duration and Frequency

Usually short — 10 to 20 minutes — and conducted monthly or quarterly depending on legal requirements or risk category.

What is a Mock Drill?

Definition

A mock drill is a realistic simulation of an emergency situation designed to test the organization’s entire emergency response system — including coordination, communication, and resource deployment.

It’s like a dress rehearsal for real emergencies, involving multiple departments, external agencies, and emergency responders.

Purpose

- To test the effectiveness of the Emergency Response Plan (ERP).

- To evaluate the speed and coordination between various response teams.

- To identify gaps in emergency procedures, manpower, and communication.

- To improve preparedness for actual disasters.

Examples

- Chemical leak mock drill.

- Fire and explosion scenario.

- Gas leak in refinery or industrial plant.

- Structural collapse in a construction site.

- Multi-casualty rescue simulation with ambulance and fire services.

Duration and Frequency

Mock drills are more elaborate — often lasting 30–60 minutes and conducted semi-annually or annually under legal compliance (as per Factories Act, National Disaster Management Authority, etc.).

Key Differences Between Safety Drill and Mock Drill

| Aspect | Safety Drill | Mock Drill |

|---|---|---|

| Purpose | To educate employees and practice response procedures | To test the organization’s full emergency preparedness system |

| Focus | Individual readiness and evacuation process | Organizational coordination and resource mobilization |

| Complexity | Simple and controlled | Realistic and detailed simulation |

| Duration | 10–20 minutes | 30–60 minutes or more |

| Participants | Employees and safety staff | Employees, safety team, external agencies (fire, ambulance, police) |

| Objective | Awareness and practice | Evaluation and improvement of ERP |

| Frequency | Monthly or quarterly | Annually or bi-annually |

| Documentation | Attendance and brief report | Full report with observations, recommendations, and corrective actions |

Why Both Drills Are Important

You might think, “If we do mock drills, do we still need safety drills?”

The answer is absolutely yes!

Safety drills build awareness and help employees act instinctively during emergencies, while mock drills test the entire emergency response system under realistic pressure.

When combined, they create a comprehensive emergency preparedness strategy.

Components of a Safety Drill

- Announcement or alarm activation

- Evacuation of the building or area

- Assembly at designated safe zones

- Headcount and roll call

- Evaluation by the safety officer

- Feedback and corrective suggestions

Example: Fire Safety Drill

- The fire alarm is triggered.

- Employees evacuate immediately via the nearest exit.

- Everyone gathers at the assembly area.

- Fire wardens verify attendance.

- Observers record evacuation time and note improvements.

Components of a Mock Drill

- Scenario creation — a simulated incident (e.g., chemical leak).

- Alarm and activation — emergency alarms and response teams activated.

- Response actions — first responders control the situation using equipment.

- Evacuation and communication — site-wide coordination, emergency team response.

- External coordination — informing authorities, fire brigade, and ambulance services.

- Post-drill debrief — lessons learned and corrective actions implemented.

Example: Chemical Spill Mock Drill

- A simulated spill occurs in a storage area.

- Emergency siren activates, and workers evacuate.

- Response team dons chemical PPE and stops the leak.

- Fire brigade and ambulance arrive for support.

- Post-drill meeting highlights communication delays and equipment gaps.

Legal and Regulatory Requirements

In India and many other countries, mock drills are legally mandated under various laws:

- Factories Act, 1948

- NDMA Guidelines (India)

- OSHA (Occupational Safety and Health Administration) in the US

- ISO 45001:2018 – Clause 8.2 on emergency preparedness and response

Organizations must document every drill — date, scenario, participants, observations, and corrective actions — as part of their safety audit trail.

How to Conduct an Effective Safety Drill

- Plan the drill — identify the type (fire, earthquake, etc.).

- Inform employees — optional (for awareness) or surprise (for real reaction).

- Assign roles — fire wardens, floor marshals, first-aiders.

- Execute and observe — note evacuation time and any confusion.

- Review and report — discuss findings in safety meetings.

Pro Tip: Use a stopwatch to record evacuation time. Aim for under 3 minutes for small buildings.

How to Conduct an Effective Mock Drill

- Define objectives and scope — e.g., test ERP for chemical leaks.

- Develop a realistic scenario — but avoid panic.

- Coordinate with external agencies — fire, police, ambulance, hospital.

- Assign observers — to monitor each team’s performance.

- Execute the drill — activate alarms, simulate rescue, control hazards.

- Post-drill analysis — document findings and improvement actions.

Pro Tip: Always hold a pre-drill briefing to avoid confusion and ensure safety during simulation.

Common Mistakes to Avoid

- Treating drills as formality rather than serious learning.

- Not involving top management in mock drills.

- Failing to review or document the outcomes.

- Choosing unrealistic or overcomplicated scenarios.

- Ignoring corrective actions after the drill.

A drill without feedback is just a performance — not a preparedness tool.

How to Measure Drill Effectiveness

To ensure both safety and mock drills serve their purpose, measure:

- Evacuation time (goal: continuous improvement)

- Response time for each emergency team

- Communication clarity during alarms

- Participation rate of employees

- Implementation rate of corrective actions

Integration into Emergency Preparedness Plan

Both safety and mock drills must align with the Emergency Preparedness and Response Plan (EPRP) of the organization.

This ensures:

- Proper coordination between internal and external responders.

- Compliance with ISO 45001 and NDMA guidelines.

- Continuous improvement through regular reviews.

Summary Table: Safety Drill vs Mock Drill

| Category | Safety Drill | Mock Drill |

|---|---|---|

| Goal | Practice safety behavior | Test emergency response system |

| Complexity | Basic | Advanced |

| Participants | Employees | Employees + external agencies |

| Documentation | Basic log | Detailed report |

| Outcome | Awareness | Performance improvement |

| Frequency | Frequent (Monthly/Quarterly) | Occasional (Annual/Semi-annual) |

Conclusion

To sum up, safety drills focus on educating employees and reinforcing correct safety behavior, while mock drills go a step further — testing the entire system under simulated stress.

Both are essential for achieving total emergency readiness.

In simple terms:

“A safety drill teaches what to do; a mock drill tests if it can actually be done.”

By combining both, organizations ensure that their workforce not only knows the procedures but can execute them efficiently in real life.

For checklist and templates visit The HSE Tools.

Behavior Based Safety (BBS) Training – Free Download

Contractor Safety Management Training Free Download

Excavation Safety Training Free Download

Machine Guarding Safety Training Free Download

First Aid Training Free Download

FAQs

Q1: What is the main purpose of a safety drill?

To train employees on how to react quickly and safely during an emergency.

Q2: How is a mock drill different from a safety drill?

A mock drill is a realistic simulation testing the full emergency system, while a safety drill focuses on awareness and practice.

Q3: How often should mock drills be conducted?

At least once every six months, depending on the risk and local regulations.

Q4: Who participates in mock drills?

Employees, safety officers, emergency response teams, and external agencies like fire or medical services.

Q5: Are records of drills mandatory?

Yes, documentation of all drills (including reports and observations) is required for audits and legal compliance.