How to Write a Weekly Safety Report – A Complete Guide for Safety Officers

Writing a Weekly Safety Report is one of the most important responsibilities of a Safety Officer. This report not only reflects the site’s safety performance but also shows your proactive efforts in monitoring hazards, mitigating risks, and ensuring compliance.

A poorly written report can give the impression that safety is not being taken seriously. But a well-structured, data-driven, and concise safety report? That shows leadership, accountability, and professionalism.

In this article, you’ll learn step-by-step how to write a Weekly Safety Report, what to include, best practices, and even receive pro tips to make your reports stand out.

What is a Weekly Safety Report?

A Weekly Safety Report is a written summary of all safety-related activities, inspections, incidents, and recommendations for improvement that occurred within a specific week on a job site or facility.

Why is a Weekly Safety Report Important?

- Tracks ongoing hazards and trends

- Helps in reviewing safety compliance

- Provides transparency to management and clients

- Assists in audits and investigations

- Encourages continuous safety improvement

Before You Start Writing: Data Collection

Before writing, gather the following:

- Daily safety reports

- Inspection checklists

- Incident/near-miss logs

- Toolbox talk registers

- PPE compliance records

- Training attendance

- Photos and evidence

- Permit to Work (PTW) records

Keep all this information ready for accurate and complete reporting.

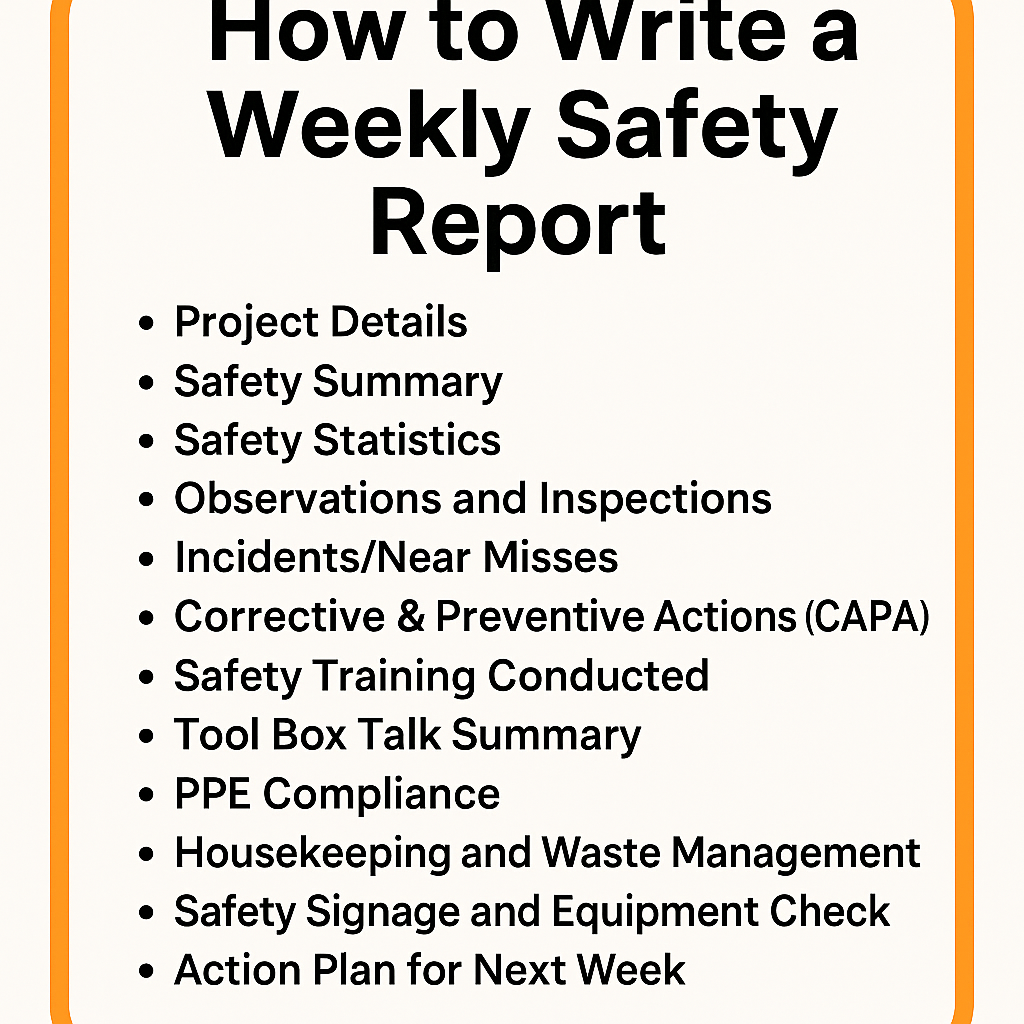

Structure of a Weekly Safety Report

Below is the ideal structure for a comprehensive report:

1. Project Details

- Project Name

- Location

- Reporting Period (Week)

- Prepared By

- Date of Submission

2. Safety Summary

A short paragraph summarizing:

- Overall site safety performance

- Any significant incidents or improvements

- Major findings or updates

3. Safety Statistics

Include:

- Total man-hours worked

- Number of workers

- Number of inspections conducted

- Toolbox talks conducted

- Safety training sessions

- Incidents, near misses, first aid cases, and lost-time injuries (LTIs)

4. Observations and Inspections

Highlight:

- Number of safety observations recorded

- Positive safety behaviors

- Unsafe acts or conditions

- Findings from site walk-throughs

Use bullet points for clarity.

5. Incidents/Near Misses

Detail:

- Any incidents reported

- Nature and cause

- Immediate actions taken

- Status of investigation

- Corrective actions initiated

Include photos or diagrams if necessary.

6. Corrective & Preventive Actions (CAPA)

Mention:

- Issues identified in previous week

- Corrective measures completed

- Outstanding actions with deadlines

Track CAPA status weekly to ensure closure.

7. Safety Training Conducted

Mention:

- Topics covered

- Dates and durations

- Number of participants

- Departments or subcontractors involved

Attach attendance sheets if applicable.

8. Tool Box Talk Summary

- Topics discussed

- Daily focus areas

- Attendance percentage

- Common worker feedback or concerns

9. PPE Compliance

- General compliance level

- Deficiencies noted

- Actions taken (e.g., warning letters, new PPE issued)

10. Housekeeping and Waste Management

- Cleanliness of the site

- Waste disposal compliance

- Chemical storage

- Fire exit clearance

- Spillage control

11. Safety Signage and Equipment Check

- Condition of safety signs and barricades

- Fire extinguisher inspections

- First aid kit updates

- Emergency lights and alarms

12. Action Plan for Next Week

- Focus areas for improvement

- Targeted safety topics

- Planned training or inspections

- Responsible persons and due dates

Step-by-Step: How to Write the Report

- Start with a header – Include your company logo, report title, project name, and reporting week.

- Write the executive summary – Mention the general safety status and any highlights.

- Input statistics – Use tables for incidents, near misses, and other data.

- Detail observations – Be objective and include both good and bad findings.

- Add photos and evidence – Visuals improve clarity and credibility.

- Summarize training and toolbox sessions – Include participant numbers.

- Review previous week’s action items – Note progress and pending items.

- Write a forward-looking action plan – Propose improvements or focus areas.

- Proofread and review – Check spelling, grammar, and accuracy of data.

- Submit on time – Send it to the Safety Manager, Project Manager, or Client.

Pro Tips to Make Your Safety Report Effective

- Be honest – Never hide incidents or violations.

- Be specific – “Poor housekeeping in welding bay” is better than “bad condition”.

- Use numbers – They speak louder than words.

- Be visual – Add charts, graphs, and photos.

- Avoid jargon – Use simple, clear language.

- Review and reflect – Mention lessons learned and areas of improvement.

Sample Template Overview

WEEKLY SAFETY REPORT

Project: ABC Tower Construction

Reporting Week: 17–23 June 2025

Prepared By: Mahendra Lanjewar

Designation: Safety Officer

1. Weekly Summary

2. Statistics Table

3. Observations & Findings

4. Incident Summary

5. Toolbox Talks Summary

6. Training Conducted

7. PPE Compliance Report

8. Housekeeping Review

9. Equipment Inspection Summary

10. Action Plan for Next Week

Attachments:

- Site photos

- Attendance sheets

- Inspection checklist

- Incident report

Conclusion

Writing a Weekly Safety Report isn’t just about filling a template—it’s about capturing the true safety performance of your site. When done correctly, it can improve communication, reduce risks, and build a culture of accountability. As a Safety Officer, treat this report as your weekly signature on site safety.

It’s not just paperwork—it’s proof of your commitment to protecting lives.

Monthly Safety Report: What Should a Safety Officer Do on a Monthly Basis

Weekly Safety Report: What Should a Safety Officer Do on a Weekly Basis

Daily Safety Report: What Should You Do on a Daily Basis as a Safety Officer

Onsite Emergency Plan under Factories Act, 1948

Off-Site Emergency Plan | Free Download

FAQs

Q1: Who should the weekly safety report be submitted to?

Typically, it’s submitted to the Safety Manager, Project Manager, or Client Representative.

Q2: How long should the report be?

2–4 pages is ideal. Be concise but comprehensive.

Q3: Can the same report format be used every week?

Yes, but the content must be updated accurately with real-time data.

Q4: Is it necessary to include photos?

Yes. Photos enhance report quality and help visualize issues or improvements.

Q5: What if nothing significant happened during the week?

Still write the report. Highlight safety compliance, good practices, and inspections done.