Job Safety Analysis vs Job Hazard Analysis: JSA vs JHA

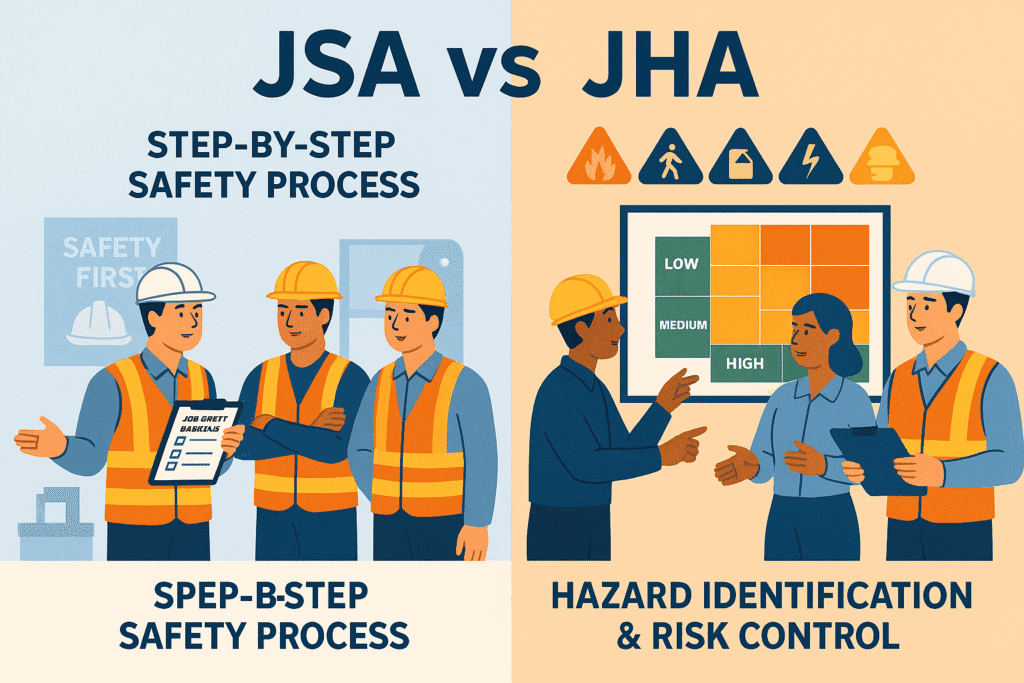

In workplace safety, few terms are as commonly used — and as frequently confused — as Job Safety Analysis (JSA) and Job Hazard Analysis (JHA).

Both are essential tools for identifying, assessing, and controlling risks before work begins. But are they the same thing?

The short answer: they’re very similar, but not entirely identical.

This article breaks down the difference between JSA and JHA, explains their steps, and shows how both help create a safer work environment.

What is Job Safety Analysis (JSA)?

Definition

A Job Safety Analysis (JSA) is a step-by-step study of a job or task to identify hazards and determine safe work procedures.

It focuses on how to perform a job safely and minimize risks through proper controls.

Purpose

- Identify hazards before starting work.

- Define safe job procedures.

- Ensure workers understand and follow correct methods.

- Improve compliance with safety standards (like OSHA, ISO 45001).

Key Focus

The JSA looks at the “job” as a process, breaking it down into individual steps — then analyzing each step for potential hazards and controls.

Example

Task: Operating a grinder

- Step 1: Inspect the tool

- Hazard: Damaged wheel may explode.

- Control: Check wheel condition, guards, and speed rating.

- Step 2: Start grinding

- Hazard: Sparks causing burns or fire.

- Control: Wear PPE, ensure no flammable materials nearby.

What is Job Hazard Analysis (JHA)?

Definition

A Job Hazard Analysis (JHA) is a technique used to identify and evaluate hazards associated with specific job tasks and determine the best methods to control or eliminate them.

Purpose

- Assess risk levels of each identified hazard.

- Determine preventive or corrective measures.

- Prioritize jobs with higher potential for injury.

Key Focus

While JSA focuses on the steps of the job, the JHA focuses more on the hazards themselves — their likelihood and severity — using a more analytical approach (risk rating, hazard type, etc.).

Example

Task: Welding on-site

- Hazard: Fire due to sparks.

- Risk Rating: Likelihood – High, Severity – Major.

- Control: Fire blanket, fire watch, permit to work, and extinguisher nearby.

So, while JSA tells you how to work safely, JHA tells you what hazards to focus on and how severe they are.

Key Differences Between JSA and JHA

| Aspect | Job Safety Analysis (JSA) | Job Hazard Analysis (JHA) |

|---|---|---|

| Purpose | To break down a job into steps and find safe methods | To identify, assess, and control hazards in each step |

| Focus | The job process | The hazards and their risk levels |

| Approach | Task-oriented | Risk-oriented |

| Outcome | Safe work procedures (SWPs) | Hazard control measures (engineering/admin/PPE) |

| Used By | Supervisors, safety officers, team leaders | Risk assessors, safety engineers |

| Output Document | Job-specific safety instruction | Hazard register or risk assessment sheet |

| Example | How to perform scaffolding safely | Hazards involved in scaffolding (falls, collapse, electrocution) |

Are JSA and JHA the Same Thing?

Technically, JSA and JHA refer to the same concept — identifying hazards in job tasks and controlling them before work starts.

However, their use varies depending on:

- Region: In the U.S., OSHA commonly uses “Job Hazard Analysis (JHA).”

- Industry: Many industrial and construction companies use “Job Safety Analysis (JSA).”

- Focus: Some organizations use both terms interchangeably, while others treat JHA as the broader process and JSA as the document or tool used.

In simple terms: Every JSA includes a JHA, but not every JHA document is a JSA.

Steps to Conduct a Job Safety Analysis (JSA)

- Select the job or task — prioritize high-risk or frequently performed ones.

- Break the job into steps — list each action in the sequence.

- Identify potential hazards — physical, chemical, mechanical, ergonomic, etc.

- Determine control measures — elimination, substitution, engineering, admin, PPE.

- Document and communicate — share the JSA with the workers.

- Review regularly — after incidents, changes, or new equipment.

Example Table Format

| Job Step | Potential Hazard | Consequence | Control Measure |

|---|---|---|---|

| Lifting material | Strain or back injury | Minor to serious injury | Use mechanical aid, correct posture |

Steps to Conduct a Job Hazard Analysis (JHA)

- Choose a job with high risk potential.

- List all hazards associated with each task step.

- Assess risk severity and likelihood.

- Apply risk rating or matrix (Low/Medium/High).

- Recommend and implement controls.

- Reassess effectiveness of controls.

Example Risk Assessment Format

| Hazard | Likelihood | Severity | Risk Level | Control Measure |

|---|---|---|---|---|

| Falling objects | Likely | Major | High | Use safety helmet, barricade area |

Example Comparison: Confined Space Entry

| Aspect | JSA Approach | JHA Approach |

|---|---|---|

| Step | Enter confined space safely | Identify confined space hazards |

| Focus | Safe sequence of entry and work | Evaluate hazards like oxygen deficiency, toxic gas |

| Control | Permit, gas test, ventilation, standby person | Risk rating (High) → Engineering + PPE controls |

Both complement each other — JSA helps define safe steps, while JHA quantifies risk and prioritizes control.

Why Both Are Important

1. Enhances Worker Awareness

Employees understand both the hazards and the safe methods to perform their jobs.

2. Supports Compliance

JSA/JHA documentation demonstrates compliance with:

- OSHA 29 CFR 1910.132(d) (Hazard Assessment)

- ISO 45001:2018 (Occupational Health and Safety Management)

3. Reduces Accidents

Both tools proactively prevent incidents by identifying risks before work starts.

4. Builds a Safety Culture

Encourages workers to think about safety daily and take ownership of their tasks.

When to Use JSA and When to Use JHA

| Situation | Recommended Tool | Reason |

|---|---|---|

| Routine, repetitive jobs | JSA | Clear step-by-step safety process |

| New or non-routine tasks | JHA | Detailed hazard evaluation |

| Permit-required jobs | Both | Combined control and documentation |

| Risk review for audits | JHA | Risk ranking and mitigation evidence |

Integration: JSA + JHA in One System

Many organizations now combine both into a single form called JSA/JHA Form, which includes:

- Job steps

- Hazards identified

- Risk rating

- Controls

- Responsible person

- Verification and review

This hybrid approach saves time and strengthens both safety planning and hazard control.

Common Mistakes in JSA/JHA Implementation

- Copy-paste approach — not job-specific.

- Conducting the analysis without involving the workers who perform the job.

- Overlooking minor hazards that can lead to major incidents.

- Failing to update after changes in equipment or procedure.

- Treating it as paperwork, not a living document.

Best Practices for Effective JSA/JHA

- Involve frontline workers. They know the job best.

- Keep it simple. Avoid overly technical jargon.

- Use photos or sketches. Visuals help in hazard identification.

- Train all staff. Ensure understanding, not just signatures.

- Review regularly. Update after incidents or process changes.

Summary Table: JSA vs JHA

| Category | JSA | JHA |

|---|---|---|

| Meaning | Study of job steps to ensure safety | Analysis of hazards to control risks |

| Approach | Step-by-step task analysis | Risk evaluation-based analysis |

| Purpose | Develop safe work procedures | Prioritize and control job hazards |

| Output | Safe Job Procedure (SJP) | Risk Assessment Report |

| Focus Area | Task sequence | Hazard risk level |

| Used In | Daily task planning | Risk management systems |

Conclusion

In summary, Job Safety Analysis (JSA) and Job Hazard Analysis (JHA) are two sides of the same safety coin.

JSA focuses on how to do the job safely, while JHA focuses on what could go wrong and how severe it could be.

When used together, they form a powerful safety management tool — helping organizations move from reactive safety to proactive prevention.

Remember: “JSA keeps you safe today; JHA keeps you safe tomorrow.”

For more checklist and templates visit The HSE Tools.

Learning from Major Accidents: Bhopal, Piper Alpha, and Rana Plaza

Fire and Explosion Hazards in Chemical Industries

Hazards and Risks in Confined Spaces: Entry & Rescue Plans

Identifying and Controlling Hazards in Manufacturing Plants

Common Hazards in Construction Sites and How to Control Them

FAQs

Q1. Are JSA and JHA interchangeable?

Yes, many organizations use the terms interchangeably, but some differentiate based on focus and structure.

Q2. Who prepares a JSA or JHA?

Usually prepared by supervisors, safety officers, or trained team members familiar with the job.

Q3. How often should JSA/JHA be reviewed?

At least annually, or after any incident, job change, or equipment modification.

Q4. What tools are used for JHA risk rating?

A standard risk matrix evaluating likelihood vs severity.

Q5. Why is JSA/JHA important for audits?

They serve as proof of hazard identification and control, fulfilling legal and ISO compliance requirements.