Layers of Protection Analysis (LOPA): A Complete Guide to Modern Risk Management

In industries such as oil & gas, chemicals, power plants, and pharmaceuticals, even a small error or equipment failure can escalate into a catastrophic accident. To prevent such outcomes, companies use structured risk assessment techniques. One of the most effective among them is Layers of Protection Analysis (LOPA).

LOPA is a semi-quantitative tool that helps safety professionals determine whether enough safeguards are in place to reduce risk to an acceptable level. It sits between purely qualitative methods (like HAZOP studies) and detailed quantitative risk assessments (QRA).

This article provides a comprehensive guide to LOPA, including methodology, key concepts, examples, case studies, advantages, limitations, and real-world applications. By the end, you’ll understand why LOPA is considered a cornerstone of process safety and occupational health management.

What is Layers of Protection Analysis (LOPA)?

Definition:

Layers of Protection Analysis (LOPA) is a semi-quantitative risk assessment technique used to evaluate accident scenarios, estimate event frequencies, and verify whether existing protective measures (called Independent Protection Layers or IPLs) are sufficient to reduce risk to tolerable levels.

👉 In simple terms:

LOPA answers the question – “Do we have enough protection layers to prevent a disaster?”

History and Evolution of LOPA

LOPA emerged in the 1990s as a bridge between HAZOP (Hazard and Operability Studies) and Quantitative Risk Assessment (QRA). The Center for Chemical Process Safety (CCPS) played a major role in developing guidelines.

- Before LOPA: Risk assessments were either too general (qualitative) or too complex (quantitative).

- With LOPA: Industries gained a practical middle ground — rigorous, yet understandable.

LOPA is now embedded in global safety standards such as:

- IEC 61508 – Functional Safety of Electrical/Electronic/Programmable Systems

- IEC 61511 – Safety Instrumented Systems (SIS) for Process Industry Sector

- OSHA PSM (Process Safety Management) in the U.S.

Purpose of LOPA

The main goals of LOPA are:

- Bridge the gap between qualitative and quantitative analysis.

- Determine adequacy of safeguards against defined risk tolerances.

- Support Safety Integrity Level (SIL) determination for safety instrumented functions.

- Improve decision-making in process design and operations.

- Enhance compliance with international safety regulations.

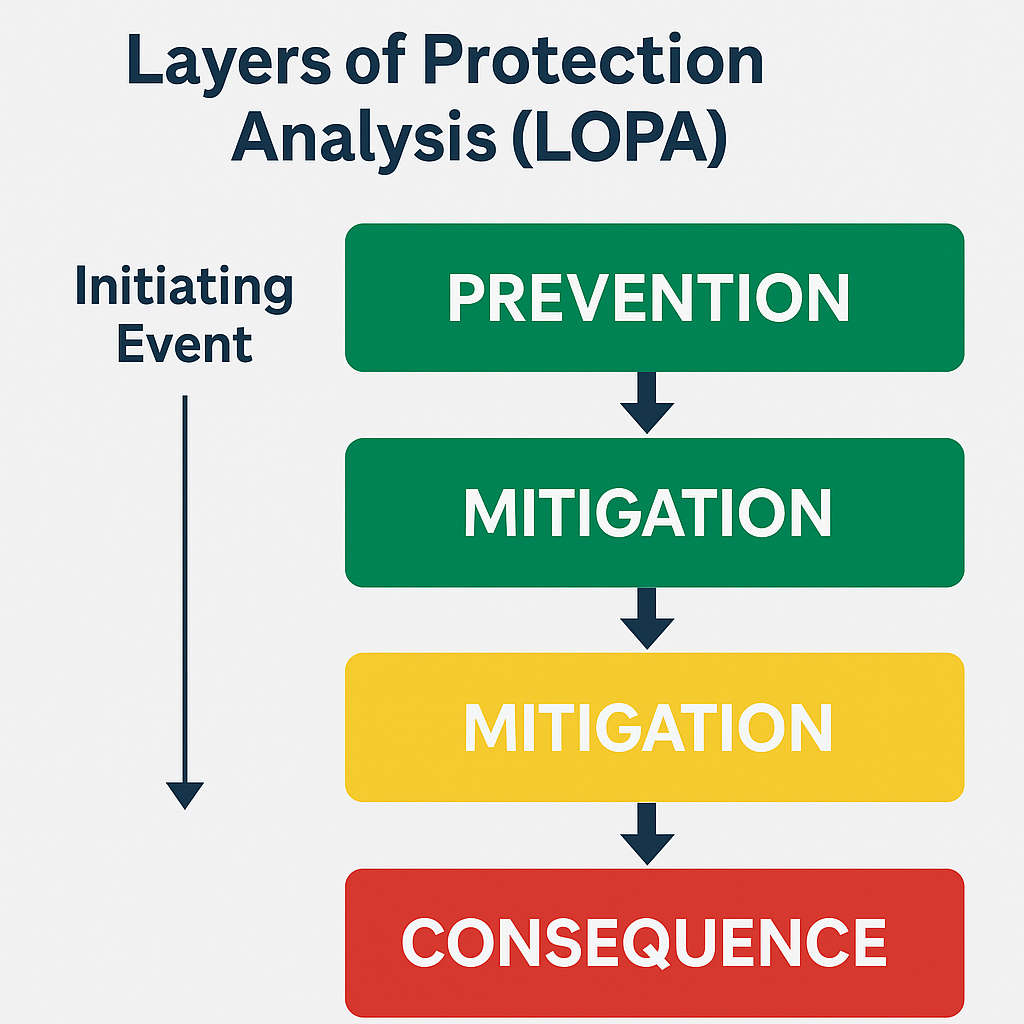

Key Concepts in LOPA

To fully understand LOPA, it’s important to clarify key terms:

- Initiating Event: The trigger that could lead to a hazardous scenario (e.g., pump seal failure).

- Consequence: The final impact if the hazard occurs (e.g., toxic release, explosion, fatality).

- Independent Protection Layer (IPL): A safeguard that reduces the likelihood of the consequence.

- Probability of Failure on Demand (PFD): The probability that an IPL fails when needed.

- Target Risk Criteria: Organizational or regulatory threshold defining acceptable risk.

Step-by-Step Methodology of LOPA

LOPA follows a structured eight-step process:

1. Select Hazard Scenario

Identify a credible scenario from HAZOP or risk review (e.g., gas leak in a compressor).

2. Identify Initiating Event

Estimate how often the initiating event may occur (e.g., 1 in 1,000 years).

3. Determine Consequence Severity

Assess potential harm: minor injury, major accident, multiple fatalities, environmental disaster.

4. Identify IPLs

List safeguards in place (alarms, relief valves, shutdown systems, dikes).

5. Assign Probability of Failure on Demand (PFD)

Each IPL is given a reliability value. Example:

- Operator response to alarm → 0.1

- Safety Instrumented System (SIS) → 0.01

- Pressure relief valve → 0.01

6. Calculate Mitigated Event Frequency

Combine initiating event frequency with IPL PFDs to get mitigated frequency.

7. Compare with Risk Tolerance Criteria

Check if final risk is within acceptable organizational or regulatory limits.

8. Decide on Additional Safeguards

If risk is still too high, add new IPLs (e.g., gas detectors, secondary containment).

Independent Protection Layers (IPLs) Explained

Not every safeguard qualifies as an IPL. To be valid, an IPL must be:

- Independent of other layers

- Specific to the hazard scenario

- Reliable with measurable PFD values

- Auditable and documented

Examples of IPLs:

- Physical Devices: Pressure relief valves, containment dikes

- Safety Instrumented Systems (SIS): Emergency shutdown systems

- Alarms with Operator Response: High-level alarms triggering manual shutdown

- Passive Safeguards: Fireproofing, blast walls

- Procedural Controls: Lockout/Tagout, evacuation protocols

Probability of Failure on Demand (PFD)

PFD values reflect the likelihood of an IPL failing when needed.

Typical PFD Values

| IPL Type | PFD Value |

|---|---|

| Basic alarm with operator response | 0.1 |

| Pressure relief valve | 0.01 |

| Safety instrumented system (SIS) | 0.01 – 0.001 |

| Dike or containment wall | 0.1 – 0.01 |

👉 Example: If an SIS has a PFD of 0.01, it means it fails once in 100 demands.

Example of LOPA Calculation

Scenario: Gas leak could lead to explosion causing multiple fatalities.

- Initiating Event Frequency = 0.1 per year

- IPLs Identified:

- Gas detection with operator action (PFD = 0.1)

- Emergency shutdown system (PFD = 0.01)

- Mitigated Event Frequency = 0.1 × 0.1 × 0.01 = 0.0001/year

👉 This means the scenario is expected once every 10,000 years, which may be acceptable depending on company criteria.

LOPA vs. Other Risk Assessment Tools

| Feature | LOPA | HAZOP | ETA | FTA |

|---|---|---|---|---|

| Approach | Semi-quantitative | Qualitative | Forward (event outcomes) | Backward (root causes) |

| Focus | IPL adequacy | Hazard identification | Accident sequences | Failure logic |

| Complexity | Medium | Low | Medium | High |

| Outcome | Risk frequency estimate | Hazard list | Probabilistic outcomes | Root cause failures |

Advantages of LOPA

- Provides structured and quantitative insight.

- Helps determine SIL requirements.

- Easier to understand than full QRA.

- Encourages team-based decision-making.

- Ensures compliance with IEC 61511.

Limitations of LOPA

- Relies on accurate frequency and PFD data.

- Can oversimplify complex interdependencies.

- Requires skilled facilitators.

- May not account for human factors adequately.

Applications of LOPA in Industries

- Oil & Gas: Preventing blowouts, refinery fires.

- Chemical Plants: Toxic gas release analysis.

- Pharmaceuticals: Reactor runaway scenarios.

- Power Generation: Boiler explosions, turbine overspeed.

- Mining & Construction: Dust explosions, crane failures.

LOPA and Safety Integrity Level (SIL)

LOPA is widely used to determine Safety Integrity Levels (SILs) for safety instrumented functions (SIFs).

SIL Categories

| SIL Level | PFD Range | Risk Reduction Factor |

|---|---|---|

| SIL 1 | 0.1 – 0.01 | 10 – 100 |

| SIL 2 | 0.01 – 0.001 | 100 – 1,000 |

| SIL 3 | 0.001 – 0.0001 | 1,000 – 10,000 |

| SIL 4 | 0.0001 – 0.00001 | 10,000 – 100,000 |

👉 Higher SIL = greater reliability required.

Tools and Software for LOPA

- exSILentia® (SIL and LOPA tool)

- PHAST (consequence modeling)

- RiskSpectrum® (probabilistic safety analysis)

- BowTieXP (bow-tie diagrams with LOPA integration)

Best Practices for LOPA

- Form a multidisciplinary team.

- Use credible data sources for PFDs.

- Document assumptions clearly.

- Review regularly (every 3–5 years or after incidents).

- Integrate with HAZOP and SIL studies.

Case Study 1: Refinery Fire

- Initiating Event: Pump seal failure → hydrocarbon leak

- IPLs: Gas detectors, ESD system, fireproofing

- Result: Frequency reduced from 1 in 100 years to 1 in 10,000 years

Case Study 2: Reactor Runaway in Pharma Plant

- Initiating Event: Cooling system failure

- IPLs: High-temperature alarm, SIS shutdown, relief valve

- Result: Safe mitigation achieved, SIL 2 system required

FAQs on LOPA

Q1: Is LOPA mandatory?

Not always, but it’s often required for high-hazard industries under regulatory standards.

Q2: Who conducts LOPA?

A multidisciplinary team including process engineers, safety experts, and operators.

Q3: How often should LOPA be updated?

Typically every 3–5 years or after major changes/accidents.

External References

FMEA (Failure Modes & Effects Analysis)

Hierarchy of Controls in Risk Assessment

Designing a 3×3 vs 5×5 Risk Matrix

Conclusion

Layers of Protection Analysis (LOPA) is a powerful semi-quantitative technique that enables organizations to evaluate whether their safety measures are adequate. By systematically analyzing hazard scenarios, IPLs, and risk frequencies, LOPA ensures that risks remain as low as reasonably practicable (ALARP).

With its balance between simplicity and rigor, LOPA has become a global standard in industries where safety is critical. As digital transformation continues, LOPA will evolve further, making workplaces safer and decision-making more data-driven.

Can’t see the content

Problem Solved