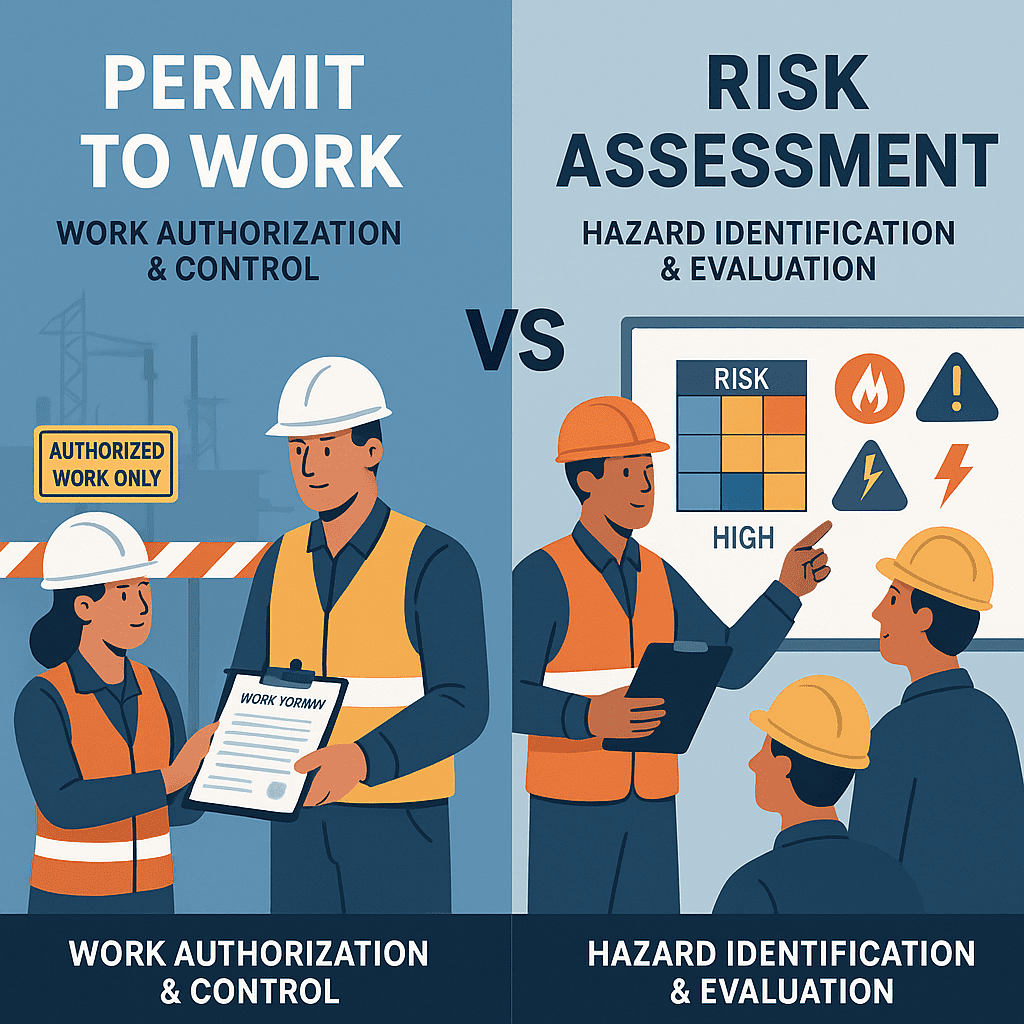

Permit to Work System vs Risk Assessment: Key Differences Explained

In the world of workplace safety, two essential systems often go hand in hand — the Permit to Work (PTW) System and the Risk Assessment (RA) process.

Many safety professionals and supervisors use both daily, but not everyone understands how they differ and how they complement each other.

This article provides a clear, detailed explanation of Permit to Work System vs Risk Assessment, their purposes, steps, interconnection, and examples from real industrial operations.

What is a Permit to Work (PTW) System?

Definition

A Permit to Work (PTW) system is a formal written authorization to perform specific high-risk work under controlled conditions.

It ensures that all necessary precautions are in place before starting the activity.

In simple terms — a PTW is the final approval to begin a task after confirming that safety measures from the risk assessment are implemented.

Purpose of PTW

- To control non-routine and hazardous activities.

- To ensure coordination between departments.

- To prevent accidents due to simultaneous operations (SIMOPS).

- To verify that risk control measures are active and effective.

- To provide traceability and accountability in safety-critical work.

Examples of Work Requiring a Permit

- Hot Work (welding, cutting, grinding)

- Confined Space Entry

- Electrical Work

- Work at Height

- Excavation

- Radiography

- Lifting operations

- Work involving isolation or energy control (LOTO)

Who Issues and Receives It

- Issuer: Authorized person (e.g., Safety Officer or Supervisor).

- Receiver: Competent person performing the work.

- Signatories: Area owner, safety department, maintenance team, and sometimes fire watch or standby person.

What is a Risk Assessment (RA)?

Definition

A Risk Assessment is a systematic process of identifying potential hazards, analyzing their risks, and determining appropriate control measures to prevent harm.

In short — a Risk Assessment is the foundation for safe work, while the Permit to Work is the execution control.

Purpose of Risk Assessment

- Identify potential hazards before work starts.

- Evaluate the likelihood and severity of harm.

- Recommend effective control measures using the hierarchy of control.

- Support decision-making for safe work planning.

- Comply with legal and organizational requirements (ISO 45001, OSHA).

Types of Risk Assessment

- Baseline RA: For general workplace conditions.

- Task-Based RA: For specific jobs or activities.

- Dynamic RA: For real-time hazard assessment during changing site conditions.

- Quantitative RA: For complex operations involving data analysis.

Key Differences Between Permit to Work and Risk Assessment

| Aspect | Permit to Work (PTW) | Risk Assessment (RA) |

|---|---|---|

| Definition | A written authorization to carry out specific hazardous work | A systematic process to identify and evaluate risks |

| Objective | To control work execution safely | To identify hazards and determine control measures |

| Focus | Ensures precautions are applied before work begins | Identifies risks and proposes preventive measures |

| Stage of Use | Implemented after risk assessment | Conducted before issuing a permit |

| Nature | Administrative control document | Analytical safety process |

| Responsibility | Permit issuer and receiver | Safety officer, supervisor, and work team |

| Output | Work permit document with authorization | Risk register or assessment form |

| Duration | Valid for a specific time (e.g., 8 or 24 hours) | Valid until work or condition changes |

| Legal Requirement | Required for high-risk jobs | Required for all risk-related activities |

| Example | Hot work permit issued after RA confirms fire controls | Identifying flammable hazards and recommending fire blankets, extinguishers, etc. |

Relationship Between PTW and Risk Assessment

While they are different tools, the Permit to Work system and Risk Assessment are interconnected:

- The Risk Assessment identifies hazards and control measures.

- The Permit to Work verifies that those control measures are implemented and maintained.

- Without a proper risk assessment, a permit cannot be issued.

- Without a permit, the identified controls cannot be enforced for certain high-risk tasks.

Simple Analogy

Think of Risk Assessment as the map, and Permit to Work as the permission to travel — you can’t move safely without first knowing the risks on the route.

Example 1: Hot Work in a Chemical Plant

- Risk Assessment identifies:

- Fire, explosion, burns, fume inhalation.

- Controls: fire extinguisher, fire watch, gas testing, PPE, and fire blanket.

- Permit to Work ensures:

- All controls from the RA are in place before welding starts.

- Fire watch and gas test certificates are verified.

Result → Safe completion of hot work without incident.

Example 2: Confined Space Entry

- Risk Assessment identifies:

- Oxygen deficiency, toxic gases, engulfment, entrapment.

- Controls: atmospheric testing, ventilation, standby person, rescue plan.

- Permit to Work ensures:

- Gas test results are valid, PPE is worn, and standby rescue is present.

- Entry is approved for a limited duration only.

Result → Compliance with confined space entry regulations (e.g., OSHA 1910.146).

Steps to Conduct a Risk Assessment

- Identify hazards — physical, chemical, biological, ergonomic, etc.

- Determine who might be harmed and how.

- Evaluate risks — use a risk matrix (likelihood × severity).

- Decide on control measures.

- Implement and monitor controls.

- Review and update periodically or after any change.

Example Risk Matrix

| Likelihood | Severity | Risk Level |

|---|---|---|

| Unlikely | Minor | Low |

| Possible | Serious | Medium |

| Likely | Major | High |

Steps in the Permit to Work Process

- Work request submitted by the team.

- Risk assessment conducted for the specific task.

- Permit preparation — detailing work location, hazards, controls, validity period, and authorized personnel.

- Review and approval by responsible authorities.

- Pre-work briefing (toolbox talk) to explain controls to the crew.

- Work execution — under supervision and compliance monitoring.

- Closure — after inspection and confirmation of safe completion.

Common Mistakes in PTW and RA Implementation

- Issuing a permit without verifying control measures.

- Conducting risk assessments only on paper without worker involvement.

- Reusing old permits for similar tasks without site-specific checks.

- Not updating RA after work condition changes.

- Poor communication between permit issuer, receiver, and team.

- Lack of training on PTW and hazard identification.

Integration in a Safety Management System

Both tools are vital components of an integrated safety management system (SMS) under ISO 45001:2018.

- Risk Assessment: Forms the basis for planning (Clause 6.1 – Risk & Opportunity).

- Permit to Work: Part of operational control (Clause 8.1 – Operational Planning & Control).

When effectively combined, they ensure both preventive and operational safety at every job site.

Benefits of Using Both Systems

For Management

- Assures legal compliance.

- Provides documentation for audits and investigations.

For Supervisors

- Ensures hazards are controlled before work begins.

- Improves coordination among teams.

For Workers

- Increases awareness of task-specific risks.

- Builds confidence to work safely.

Summary Table: PTW vs RA

| Parameter | Permit to Work (PTW) | Risk Assessment (RA) |

|---|---|---|

| Purpose | Authorize and control hazardous work | Identify and assess hazards |

| Timing | After RA, before starting work | Before work planning |

| Duration | Temporary (specific task) | Ongoing until review |

| Focus | Compliance and verification | Prevention and analysis |

| Output | Permit document | Risk evaluation matrix |

| Example Use | Hot work, confined space entry | Workplace hazard assessment |

Conclusion

In summary, the Risk Assessment identifies what can go wrong and how to prevent it, while the Permit to Work System ensures those preventive measures are actually implemented before and during work.

They are not alternatives but complementary safety tools — one for planning, the other for execution control.

“A risk assessment saves you from surprises, and a permit to work saves you from consequences.”

Organizations that use both effectively create a proactive, documented, and reliable safety culture — one that prevents accidents before they even start.

For more checklist and templates visit The HSE Tools.

Learning from Major Accidents: Bhopal, Piper Alpha, and Rana Plaza

Fire and Explosion Hazards in Chemical Industries

Hazards and Risks in Confined Spaces: Entry & Rescue Plans

Identifying and Controlling Hazards in Manufacturing Plants

Common Hazards in Construction Sites and How to Control Them

FAQs

Q1. Can a permit to work be issued without a risk assessment?

No. A valid risk assessment must be completed before issuing any permit.

Q2. Who is responsible for risk assessment?

Supervisors and safety officers, with input from workers performing the job.

Q3. How long is a permit valid?

Typically for one shift (8–24 hours) or until the job or condition changes.

Q4. What is the role of a safety officer in PTW?

To verify that all controls identified in the risk assessment are in place before signing the permit.

Q5. Are PTW and RA required for routine jobs?

Risk assessments are required for all tasks. PTWs are specifically required for high-risk, non-routine jobs.