Proactive Safety vs Reactive Safety

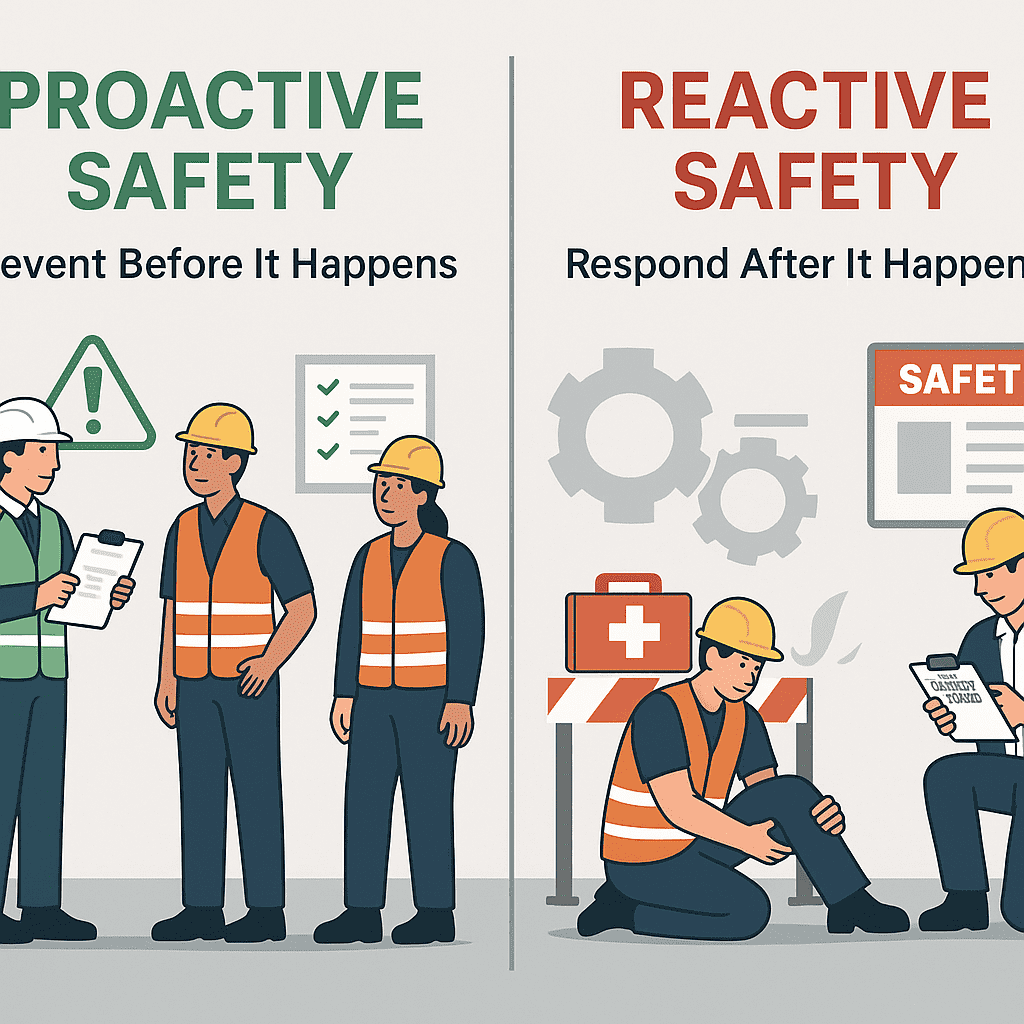

What’s better: preventing an accident before it happens, or learning from one after it occurs?

That’s the essence of Proactive Safety vs Reactive Safety — two distinct approaches that shape how organizations manage workplace risks.

In simple terms, proactive safety is about anticipation and prevention, while reactive safety is about response and correction.

Both play important roles, but proactive safety is what separates compliance-driven organizations from truly safety-driven cultures.

Let’s dive deeper into their meaning, differences, benefits, and how you can shift your organization from being reactive to proactive.

What is Proactive Safety?

Definition

Proactive safety focuses on identifying, assessing, and controlling risks before incidents occur.

It’s about anticipation, prevention, and continuous improvement — not waiting for accidents to happen before taking action.

Key Characteristics

- Based on early warning signs and leading indicators.

- Encourages employee participation in hazard identification.

- Uses data and trends to prevent incidents.

- Embeds safety into daily work culture, not just procedures.

Examples of Proactive Safety Measures

- Conducting risk assessments before starting work.

- Performing regular safety audits and inspections.

- Encouraging near miss reporting and safety observations.

- Running behavior-based safety (BBS) programs.

- Providing continuous safety training and toolbox talks.

- Tracking leading indicators like participation, observation rates, and corrective actions closed.

“Proactive safety doesn’t wait for an accident — it prevents one.”

What is Reactive Safety?

Definition

Reactive safety focuses on responding after an incident has occurred.

It’s about investigating, reporting, and taking corrective actions to avoid recurrence.

Key Characteristics

- Driven by lagging indicators like injury rates and lost-time incidents.

- Often initiated after something goes wrong.

- Focuses on damage control and compliance.

- Lacks predictive or preventive action until after incidents.

Examples of Reactive Safety Measures

- Investigating accidents and near misses.

- Implementing corrective actions after incidents.

- Updating procedures only after non-compliance is discovered.

- Conducting retraining following violations or injuries.

- Relying heavily on incident statistics (TRIR, LTIR) for safety performance.

“Reactive safety treats the symptom; proactive safety cures the cause.”

Key Differences Between Proactive and Reactive Safety

| Aspect | Proactive Safety | Reactive Safety |

|---|---|---|

| Approach | Prevention-focused | Response-focused |

| Timing | Before an incident | After an incident |

| Goal | Eliminate or reduce hazards early | Investigate and fix after harm |

| Indicators | Leading (observations, audits, training) | Lagging (injuries, incidents, downtime) |

| Data Source | Trends, near misses, employee feedback | Accident reports, investigations |

| Culture Type | Predictive and preventive | Compliance and corrective |

| Responsibility | Shared by everyone | Driven by management or safety team |

| Example | Conducting HIRA before work | Conducting an investigation after an injury |

Why Proactive Safety Is Better for Modern Workplaces

In today’s complex industries, waiting for something to go wrong is not an option.

A proactive safety approach:

- Prevents accidents before they occur.

- Builds worker confidence and participation.

- Reduces downtime and loss.

- Enhances compliance automatically.

- Creates a strong safety culture that values prevention over punishment.

Reactive safety, on the other hand, keeps organizations stuck in a loop of incident → investigation → correction → repeat.

The Role of Leading and Lagging Indicators

Leading Indicators (Proactive Metrics)

Measure what you do to prevent incidents.

Examples:

- Number of safety observations reported.

- Completion of safety training.

- Frequency of toolbox talks.

- Preventive maintenance completed on schedule.

- Corrective actions closed on time.

Lagging Indicators (Reactive Metrics)

Measure what has already happened.

Examples:

- Number of injuries or illnesses.

- Lost-time incident rate.

- Damage to property or equipment.

- Number of first-aid or medical cases.

A world-class safety system tracks both — but puts more emphasis on leading indicators, because they drive improvement.

Example Scenarios

Scenario 1: Equipment Failure

- Reactive Response: Waits until the machine fails and injures someone before fixing it.

- Proactive Response: Schedules preventive maintenance, identifies wear early, and replaces parts before failure.

Scenario 2: Fire Hazard

- Reactive Response: Installs a new fire extinguisher only after a fire breaks out.

- Proactive Response: Conducts regular inspections, ensures fire load is minimized, and provides training on fire watch.

Scenario 3: Worker Behavior

- Reactive Response: Disciplinary action after unsafe act.

- Proactive Response: Behavior-based observation and coaching to correct the act before it leads to an incident.

How to Shift from Reactive to Proactive Safety

- Encourage Near Miss and Observation Reporting

Reward employees for reporting — not hiding — unsafe acts or conditions. - Use Data and Trend Analysis

Track safety observations, training completion, and audit findings to identify patterns early. - Engage Employees in Safety Decisions

Involve workers in risk assessments, inspections, and toolbox talks. - Invest in Training and Awareness

Continuous education builds competence and confidence to act safely. - Leadership Commitment

Safety culture starts from the top — leaders must walk the talk. - Measure Leading Indicators

Focus KPIs on preventive actions rather than just incident rates. - Integrate Safety into Operations

Safety should not be an extra step — it should be part of how work is done daily.

Benefits of Proactive Safety Approach

1. Reduces Accidents and Losses

By identifying hazards before harm occurs, organizations save lives and resources.

2. Builds Stronger Safety Culture

Employees feel valued and responsible for maintaining a safe workplace.

3. Enhances Productivity

Fewer disruptions mean smoother operations and higher morale.

4. Ensures Legal and ISO Compliance

Proactive systems align naturally with ISO 45001, OSHA, and other standards.

5. Improves Reputation

Clients and regulators trust organizations that act before problems arise.

Challenges of Reactive Safety Systems

- Safety actions only after injuries.

- Limited learning from near misses.

- Focus on compliance, not culture.

- Workers hesitate to report hazards.

- Management views safety as cost, not investment.

Over time, this leads to higher incident rates and a weak safety culture.

Integration of Both Approaches

While proactive safety is ideal, a balanced system uses both approaches effectively:

- Proactive: Prevention, observation, and anticipation.

- Reactive: Investigation, correction, and learning.

The key is to reduce dependency on reactive actions while continuously expanding proactive measures.

Summary Table: Proactive vs Reactive Safety

| Category | Proactive Safety | Reactive Safety |

|---|---|---|

| Mindset | Prevention and prediction | Reaction and correction |

| Timing | Before incident | After incident |

| Focus | Identifying and eliminating risks | Investigating and fixing failures |

| Data Type | Leading indicators | Lagging indicators |

| Outcome | Fewer incidents and improved culture | Temporary fixes and repeated issues |

| Example | Conducting safety audits | Conducting accident investigation |

Conclusion

In conclusion, proactive safety is about taking control, while reactive safety is about catching up.

Organizations that focus only on reactive measures remain in a cycle of accidents and corrections, while proactive systems anticipate risks and eliminate them early.

“Reactive safety saves you after an accident. Proactive safety saves you before it happens.”

To build a world-class safety culture, start measuring what prevents accidents, not just what happens after them.

For checklist templates visit The HSE Coach.

What are the 7 Steps of Safety?

Static Electricity Hazards in the Workplace

How to Conduct a Fire Drill: Step-by-Step Safety Officer Guide

Key Definitions: Health, Safety and Welfare with Examples

FAQs

Q1. Can a safety program be 100% proactive?

Not entirely. Some level of reactivity is needed to learn from incidents, but the goal is to minimize it.

Q2. What is an example of a proactive safety metric?

Number of safety audits, near misses reported, or training hours completed.

Q3. What is an example of a reactive safety measure?

Corrective action implemented after an accident investigation.

Q4. Why do organizations remain reactive?

Because proactive systems require time, training, and cultural change, which many overlook.

Q5. What’s the best way to move from reactive to proactive safety?

Encourage open reporting, focus on leading indicators, and make safety a shared responsibility.