SWP vs SOP: Safe Work Procedure vs Standard Operating Procedure

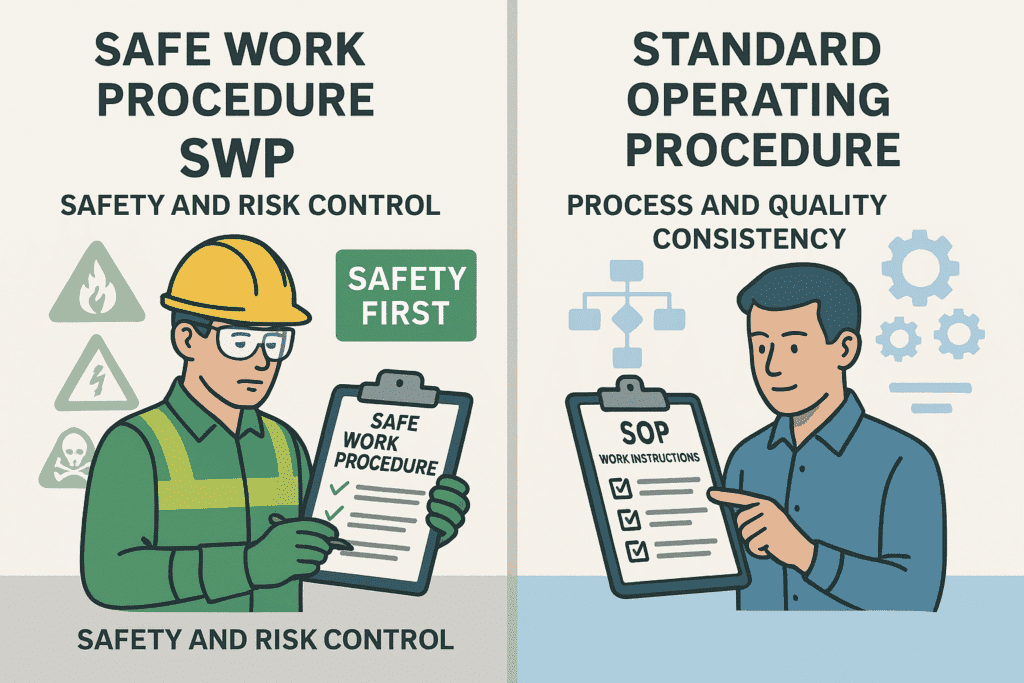

In occupational safety and operations management, two important documents — Safe Work Procedures (SWPs) and Standard Operating Procedures (SOPs) — often create confusion.

Both provide instructions on how work should be performed, but they serve different purposes.

In short:

- SOPs focus on efficiency and consistency in performing tasks.

- SWPs focus on safety and risk control while performing those tasks.

This article explains their meanings, purposes, structure, key differences, and practical examples to help you implement both effectively in your workplace.

What is a Standard Operating Procedure (SOP)?

Definition

A Standard Operating Procedure (SOP) is a detailed, step-by-step instruction document that describes how to perform a specific process or operation consistently and efficiently.

It ensures that tasks are carried out uniformly, reducing errors and maintaining quality across operations.

Purpose of SOP

- To standardize work methods.

- To ensure consistent product or service quality.

- To reduce variation and improve efficiency.

- To train new employees effectively.

- To comply with process or industry standards (e.g., ISO 9001, GMP).

Structure of an SOP

- Title and Purpose – Identifies the process and its goal.

- Scope – Defines where and when it applies.

- Responsibilities – Identifies who performs the steps.

- Definitions/References – Clarifies terms or standards.

- Procedure Steps – Lists actions in order.

- Documentation/Records – Specifies required forms or data.

- Revision History – Tracks updates.

Example of an SOP

SOP Title: Machine Startup Procedure

Purpose: To ensure safe and consistent startup of production machinery.

Steps: Check power supply and equipment readiness, Ensure guards are in place, Press the “Start” button, Observe operation for abnormalities.

What is a Safe Work Procedure (SWP)?

Definition

A Safe Work Procedure (SWP) is a step-by-step description of how to perform a job safely by identifying potential hazards and specifying control measures to prevent accidents or injuries.

It is developed based on a risk assessment and focuses primarily on hazard control and worker protection.

Purpose of SWP

- To eliminate or minimize workplace hazards.

- To ensure safe performance of high-risk tasks.

- To promote compliance with OHS regulations (e.g., OSHA, ISO 45001).

- To serve as a safety training and communication tool.

- To protect employees, contractors, and visitors.

Structure of an SWP

- Job/Task Title

- Purpose/Scope

- Hazards Identified

- Control Measures

- Required PPE

- Step-by-Step Safe Work Method

- Emergency Procedures

- References (Risk Assessment, Legislation, etc.)

- Approval and Review Date

Example of an SWP

SWP Title: Working at Height

Hazards: Falls, dropped tools, structural instability.

Controls: Full body harness, guardrails, inspection before use.

Procedure: Conduct pre-task inspection, Secure harness and lifeline, Ensure area below is barricaded, Work within designated area only.

Key Differences Between SWP and SOP

| Aspect | Standard Operating Procedure (SOP) | Safe Work Procedure (SWP) |

|---|---|---|

| Purpose | To ensure operational efficiency and consistency | To ensure safety and prevent incidents |

| Focus | Quality, productivity, process standardization | Hazard identification and risk control |

| Origin | Process or quality management systems (e.g., ISO 9001) | Safety management systems (e.g., ISO 45001, OSHA) |

| Content | Task instructions | Task instructions + hazard controls |

| Audience | Operators, technicians, managers | Workers, safety officers, supervisors |

| Development Basis | Best practice and manufacturer instructions | Risk assessment (JSA/JHA/HIRA) |

| Objective | Do the job right | Do the job safely |

| Example | How to operate a machine correctly | How to operate a machine safely |

| Regulatory Requirement | Quality and compliance standards | Occupational health and safety laws |

| Document Owner | Quality or Operations department | Health, Safety & Environment (HSE) department |

Relationship Between SWP and SOP

While they serve different purposes, SOPs and SWPs complement each other:

- SOPs provide how to do the job efficiently, while

- SWPs provide how to do it safely.

For example:

SOP: “Start the conveyor belt after checking all controls.”

SWP: “Ensure no one is standing on or near the conveyor before starting it.”

In many organizations, both are integrated into a single document — called an “Operational and Safety Procedure” — for simplicity.

Example Scenario

Task: Welding Operations

| SOP Perspective | SWP Perspective |

|---|---|

| – Ensure welding machine is functioning properly. | – Ensure hot work permit is approved. |

| – Follow welding sequence as per drawing. | – Wear welding PPE and use fire screens. |

| – Maintain proper welding current and voltage. | – Keep fire extinguisher nearby. |

| – Record welding parameters. | – Conduct post-welding area fire watch. |

Result: The SOP ensures quality welds, while the SWP ensures safe performance.

Benefits of Having Both SOPs and SWPs

For Management:

- Clear documentation for compliance and audits.

- Improved efficiency and reduced rework.

- Lower incident rates and legal risk.

For Workers:

- Clear instructions reduce confusion.

- Enhanced awareness of hazards and controls.

- Confidence in performing jobs safely and correctly.

For Organizations:

- Demonstrates compliance with safety and quality standards.

- Builds a culture of operational excellence.

- Enhances reputation and employee morale.

Integration in Safety Management Systems

| ISO 45001 Clause | Document Role |

|---|---|

| 5.2 – Policy | SWP aligns with safety commitments |

| 8.1 – Operational Planning | SOP defines processes |

| 8.2 – Hazard Identification | SWP defines controls |

| 9.1 – Performance Evaluation | Both provide measurable indicators |

Integration ensures the organization addresses both efficiency and safety within the same system.

How to Develop an SWP

- Identify the high-risk task.

- Conduct a Job Safety Analysis (JSA).

- List all potential hazards and control measures.

- Write step-by-step safe methods.

- Include PPE and emergency requirements.

- Review and approve by safety management.

- Train workers and make SWP accessible.

How to Develop an SOP

- Identify routine operational tasks.

- Consult experienced personnel.

- Document steps in clear, simple language.

- Add references, tools, and quality checks.

- Validate through trial runs.

- Train operators and review periodically.

Common Mistakes Organizations Make

- Confusing SOPs with SWPs and using them interchangeably.

- Writing lengthy, unreadable procedures.

- Not involving end-users during development.

- Failing to update documents after incidents or process changes.

- Overlooking hazard controls in SOPs.

Best Practice: Combine Safety and Operations

The most effective organizations merge SOPs and SWPs into a single document with dual focus — safe and efficient performance.

Template Example

| Step | Action (SOP) | Hazard (SWP) | Control Measure |

|---|---|---|---|

| 1 | Switch on welding machine | Electric shock | Use insulated gloves |

| 2 | Perform welding | Fire or burns | Wear PPE, fire watch standby |

| 3 | Switch off and cool equipment | Hot surface | Allow cooling time, use tools |

Summary Table: SWP vs SOP

| Parameter | Safe Work Procedure (SWP) | Standard Operating Procedure (SOP) |

|---|---|---|

| Focus | Safety | Quality & Efficiency |

| Goal | Prevent accidents | Maintain consistency |

| Developed From | Risk Assessment | Process Requirement |

| Ownership | HSE Department | Operations/Quality Department |

| Outcome | Safe Work Environment | Standardized Operations |

| Example | Safe Lifting Procedure | Lifting Operation Steps |

Conclusion

In short, Safe Work Procedures (SWPs) keep people safe, while Standard Operating Procedures (SOPs) keep processes efficient.

They are not competitors but complements — one protects workers, the other perfects performance.

“An SOP shows how to do the job right; an SWP ensures you go home safe after doing it.”

Together, they form the backbone of a safe, productive, and compliant workplace.

For checklist and templates visit The HSE Tools.

Safety Policy vs Safety Manual

Construction Safety Checklist Generator – Complete Guide for Safety Professionals

Training Attendance Sheet Generator – Complete Guide for Safety Professionals

Safety Induction Checklist Generator – Complete Guide for Safety Professionals

Toolbox Talk Generator – Complete Guide for Safety Professionals

FAQs

Q1. Can a company have both SOP and SWP for the same task?

Yes. Many high-risk jobs require both — one for process standardization, the other for hazard control.

Q2. Who prepares SWPs and SOPs?

SWPs are developed by the safety department with input from workers, while SOPs are created by operations or quality departments.

Q3. How often should they be reviewed?

At least once a year or after any change in process, equipment, or incident.

Q4. Are SWPs legally required?

Yes, for high-risk activities under OSHA, ISO 45001, and national OHS laws.

Q5. Can SWPs and SOPs be combined?

Yes, combining them into one document is common and helps simplify compliance and training.