How to Make HIRA on Work At Height?

How to Make HIRA on Work At Height : In the world of safety and risk management, HIRA (Hazard Identification and Risk Assessment) is a crucial process. It’s especially vital when it comes to work at height activities, which inherently carry a higher level of risk. In this comprehensive guide, we will delve into the process of creating a HIRA specifically tailored to work at height activities.

Introduction to Work at Height

Work at height involves any task performed above ground level, where a person could fall and potentially injure themselves. It can include activities like construction, maintenance, window cleaning, or even changing a lightbulb on a ladder. While these tasks are essential, they come with a level of risk that requires careful consideration.

Understanding HIRA

HIRA, as mentioned earlier, stands for Hazard Identification and Risk Assessment. It’s a systematic approach used to identify potential hazards and assess the associated risks. This process enables organizations to implement control measures to minimize or eliminate these risks.

Why HIRA Matters in Work at Height Activities

Work at height is inherently risky. Falls from height are a leading cause of workplace injuries and fatalities worldwide. HIRA plays a pivotal role in ensuring the safety of workers engaged in such activities. It allows organizations to proactively identify hazards and take measures to protect their employees.

The HIRA Process: Step by Step

Identifying Hazards

The first step in the HIRA process is to identify potential hazards in work at height activities. These can range from unstable surfaces to inadequate fall protection equipment. A thorough inspection and risk assessment of the work area are critical.

Assessing the Risks

Once hazards are identified, the next step is to assess the associated risks. This involves determining the likelihood and severity of potential incidents. Risks can be categorized as low, medium, or high.

Implementing Control Measures

Based on the risk assessment, control measures are implemented to reduce or eliminate hazards. This may include providing safety harnesses, guardrails, and safety training for workers.

Regular Monitoring

Work at height HIRA is an ongoing process. Regular monitoring ensures that control measures remain effective and that new hazards are promptly addressed.

Key Elements in Work at Height HIRA

To create an effective HIRA for work at height activities, consider the following key elements:

Equipment Inspection

Regular inspection of equipment, such as ladders, scaffolds, and safety harnesses, is essential to ensure they are in good working condition.

Training and Competency

Proper training and competency assessments of workers are vital to ensure they are capable of performing their tasks safely.

Emergency Response Planning

Having a well-defined emergency response plan in case of accidents or falls is crucial.

Legal Compliance

Organizations must comply with relevant safety regulations and standards when performing work at height. Non-compliance can result in legal issues and, more importantly, jeopardize worker safety.

Hierarchy of Controls

The hierarchy of controls should be applied in work at height HIRA. This includes eliminating the hazard, substituting it with something less hazardous, engineering controls, administrative controls, and, as a last resort, personal protective equipment.

Documentation and Record-Keeping

Maintaining records of HIRA and control measures is essential for accountability and continuous improvement.

Scenario: Repainting a Water Tower

Background: A small town in the countryside has a water tower that provides clean drinking water to the entire community. Over time, the tower’s paint has deteriorated, and it’s time for a fresh coat. This task involves work at height.

Step 1: Identifying Hazards

- Hazard: Falling from a significant height while working on the water tower.

- Hazard: Weather conditions, including strong winds, rain, and lightning.

- Hazard: Potential equipment malfunctions, like a malfunctioning safety harness.

Step 2: Assessing Risks

- The likelihood of a fall is low if proper safety measures are in place.

- The severity of a fall could be high, leading to severe injuries or fatalities.

- Weather conditions can vary; some days may be riskier than others.

- Regular equipment inspections can mitigate equipment-related risks.

Step 3: Implementing Control Measures

- Provide workers with appropriate fall protection equipment, such as safety harnesses and guardrails.

- Monitor weather conditions daily and postpone work during adverse weather.

- Conduct equipment inspections before each workday and provide replacements or repairs as needed.

Step 4: Regular Monitoring

- Assign a safety officer to monitor weather conditions and ensure that workers are adhering to safety protocols.

- Conduct surprise safety checks to ensure that equipment is in good condition.

Key Elements in Work at Height HIRA

- Regularly inspect the water tower structure to identify potential weaknesses.

- Train workers in the proper use of safety equipment and emergency procedures.

- Develop an emergency response plan that includes rescue procedures for anyone who may fall.

Legal Compliance

- Ensure that the work complies with local safety regulations and standards, including OSHA (Occupational Safety and Health Administration) guidelines.

Hierarchy of Controls

- Eliminate hazards by thoroughly inspecting and maintaining the water tower.

- Substitution is not feasible in this scenario.

- Use engineering controls like guardrails.

- Administrative controls include monitoring weather conditions.

- Personal protective equipment (PPE) such as safety harnesses is the last line of defense.

Documentation and Record-Keeping

- Maintain records of daily safety checks, equipment inspections, and any safety incidents or near-misses.

Conclusion By conducting a HIRA for the water tower painting project, the town ensures the safety of the workers involved in this critical maintenance task. Through hazard identification, risk assessment, and the implementation of control measures, the chances of accidents and injuries are significantly reduced.

Remember, the HIRA process is adaptable and should be applied to various work at height scenarios to ensure the safety and well-being of workers in these situations.

Case Study: A Successful Work at Height HIRA

Let’s take a look at a case study of a company that implemented a robust HIRA for their work at height activities and significantly reduced accidents and injuries.

Common Challenges and Pitfalls

Work at height HIRA can face challenges like employee resistance, insufficient resources, or lack of expertise. Identifying and addressing these challenges is critical for success.

The Role of Communication

Effective communication is vital in the HIRA process. Employees must be aware of the identified hazards, risks, and control measures.

Continuous Improvement

HIRA is not a one-time task. Regular reviews and updates are necessary to adapt to changing work conditions and emerging hazards.

Conclusion

Creating a HIRA for work at height activities is a proactive approach to ensuring the safety of workers. By identifying hazards, assessing risks, and implementing control measures, organizations can significantly reduce the likelihood of accidents and injuries.

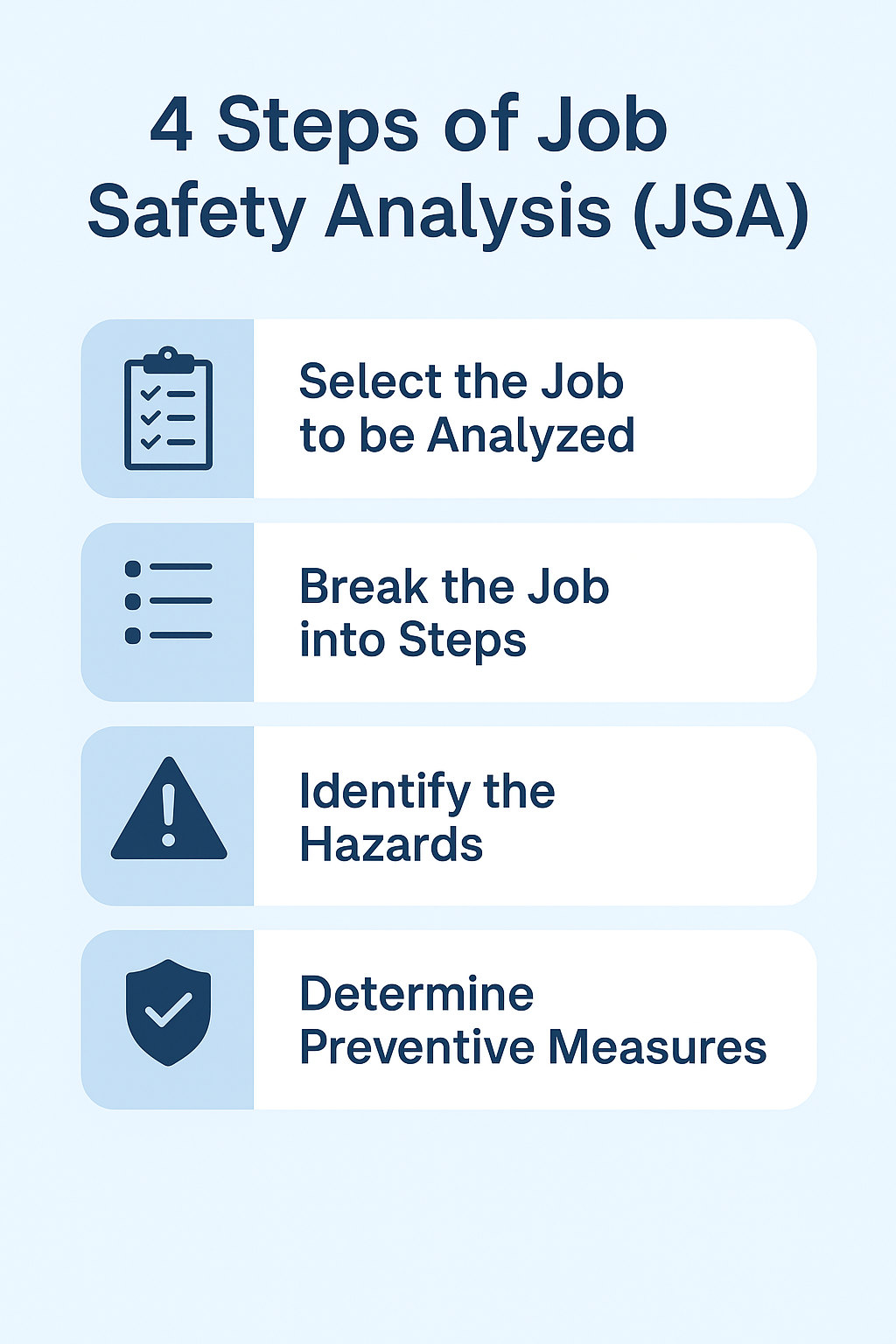

How to Conduct Risk Assessment

How to Prepare JSA (Job Safety Analysis)?

FAQs

FAQ 1: What are the primary hazards associated with work at height activities?

Work at height hazards can include falls, unstable surfaces, inadequate safety equipment, and environmental factors like wind and weather conditions.

FAQ 2: Can you provide an example of a risk assessment for a specific work at height scenario?

Certainly! Let’s consider a scenario where a worker needs to repair a rooftop HVAC unit. A risk assessment would involve identifying potential fall hazards, assessing the severity of a fall, and implementing control measures like using fall arrest systems.

FAQ 3: How often should a HIRA be reviewed and updated for work at height activities?

HIRA should be reviewed regularly, especially when there are changes in work processes, equipment, or work environments. As a general rule, at least annually.

FAQ 4: What should employees do if they identify a hazard during a work at height activity?

Employees should immediately report the hazard to their supervisor and cease work in the hazardous area until the issue is resolved.

FAQ 5: Are there specific regulations that govern work at height activities in different regions?

Yes, regulations can vary by region. It’s essential to be aware of and comply with local and national safety regulations when performing work at height activities.

This article serves as a comprehensive guide to creating a HIRA for work at height activities. By following these steps and best practices, organizations can significantly enhance the safety of their employees and reduce the risk associated with work at height.