How to Make HSE Plan

Introduction to HSE Plans

Health, Safety, and Environment (HSE) plans serve as foundational blueprints for organizations, ensuring a safe and secure work environment while preserving the environment’s integrity. These plans are crucial across industries, outlining strategies to mitigate risks, prevent accidents, and promote a culture of safety.

Understanding the Importance of HSE Plans

HSE plans are not just regulatory requirements but pivotal in safeguarding human lives, preserving assets, and upholding an organization’s reputation. They encompass strategies that prioritize the well-being of employees, the community, and the environment.

Key Components of an HSE Plan

Risk Assessment and Management

An effective HSE plan begins with a comprehensive risk assessment, identifying potential hazards and assessing their impact. It involves categorizing risks and strategizing mitigation measures.

Safety Procedures and Protocols

Implementing stringent safety procedures and protocols is fundamental. This includes guidelines for personal protective equipment (PPE), safe work practices, and emergency procedures.

Emergency Response Plans

Crafting detailed emergency response plans is critical. It involves outlining procedures for various scenarios, conducting drills, and ensuring swift responses during crises.

Training and Education

Education and training form the backbone of an HSE plan. Equipping employees with necessary skills and knowledge enhances their ability to identify risks and respond appropriately.

Creating an Effective HSE Plan

Gathering Information and Resources

Begin by collecting data on existing risks, industry standards, and legal requirements. Leverage expertise and consult professionals to gather comprehensive information.

Setting Clear Objectives

Define specific, measurable, achievable, relevant, and time-bound (SMART) objectives. Tailor objectives to address identified risks and align with organizational goals.

Engaging Stakeholders

Involving all stakeholders fosters a sense of ownership and commitment. Collaborate with employees, management, and external entities to garner support and diverse perspectives.

Drafting the Plan

Formulate a detailed plan encompassing identified risks, mitigation strategies, protocols, training schedules, and emergency response procedures.

Creating an HSE (Health, Safety, and Environment) plan involves several key steps:- Assessment and Identification: Identify potential hazards in the workplace or project site. This includes physical hazards, chemical exposure risks, environmental concerns, etc.

- Regulatory Compliance: Understand and comply with local, regional, and national safety regulations and standards applicable to your industry.

- Goal Setting: Define specific health, safety, and environmental goals for the project or workplace. These goals should be measurable and achievable within a set timeframe.

- Risk Management: Develop strategies to mitigate identified risks. This may involve implementing safety procedures, providing personal protective equipment (PPE), conducting training sessions, etc.

- Emergency Preparedness: Create a plan for responding to emergencies, including evacuation procedures, first aid kits, emergency contacts, etc.

- Training and Communication: Educate employees or team members about the HSE plan. Communication is key to ensuring everyone understands their roles and responsibilities regarding health, safety, and the environment.

- Monitoring and Evaluation: Regularly assess the effectiveness of the HSE plan. This involves conducting inspections, gathering feedback, and making necessary adjustments to improve safety measures.

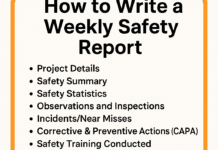

- Documentation and Reporting: Maintain accurate records of incidents, near misses, safety inspections, training sessions, and other relevant data. Reporting any incidents promptly is crucial for analysis and prevention.

Remember, an HSE plan should be a living document that evolves as the project progresses and new risks emerge. Collaboration among all stakeholders is vital to its success.Implementing and Monitoring the HSE Plan

Rolling Out the Plan

Execute the plan systematically, ensuring adequate training and communication. Implement feedback mechanisms to address challenges and adapt strategies as needed.

Regular Evaluation and Updates

Continuous monitoring and evaluation are vital. Regularly review the plan’s efficacy, update protocols based on evolving risks, and revise training programs for ongoing improvement.

Benefits of a Well-Executed HSE Plan

A meticulously executed HSE plan cultivates a culture of safety, reduces accidents, minimizes downtime, and enhances employee morale, fostering a productive work environment.

Here's a sample example illustrating the implementation of an HSE plan:Scenario: XYZ Construction Company

XYZ Construction Company, a leading player in the construction industry, implemented a robust HSE plan to ensure the safety of its workers and the surrounding environment during its large-scale infrastructure projects.

1. Risk Assessment and Management: The company conducted thorough risk assessments before commencing any project. This involved identifying potential hazards such as working at heights, heavy machinery operation, and hazardous materials.

2. Safety Procedures and Protocols: Strict safety protocols were established, including mandatory use of personal protective equipment (PPE), regular safety training, and implementing safety signage across the construction site.

3. Emergency Response Plans: Detailed emergency response plans were devised, outlining procedures for various scenarios like fire outbreaks, medical emergencies, and natural disasters. Regular drills ensured preparedness among workers.

4. Training and Education: XYZ Construction Company invested in comprehensive training programs. Workers were trained not only in safety protocols but also in hazard identification and reporting, fostering a proactive safety culture.

5. Implementation and Monitoring: The HSE plan was systematically implemented across all projects. Regular inspections, safety audits, and incident reporting mechanisms were in place to monitor the plan’s effectiveness.

Result: The implementation of the HSE plan significantly reduced the number of workplace accidents and injuries. Employee morale and confidence in safety measures increased, resulting in improved productivity and project efficiency. Moreover, the company’s reputation for adhering to high safety standards enhanced its credibility in the industry.

This exemplifies how a well-crafted and diligently executed HSE plan can positively impact both the workforce and the company's operations, ensuring a safer and more efficient working environment.Conclusion

Crafting an effective HSE plan involves a meticulous approach, integrating risk assessment, proactive measures, and continuous evaluation. It’s a cornerstone in ensuring a safe and productive work environment for all.

Emergency Planning Ideas for Effective Disaster Management

Emergency Planning and Response

Emergency Planning and Preparedness

FAQs

- What industries benefit most from HSE plans? HSE plans are invaluable across various industries like construction, manufacturing, healthcare, oil and gas, and transportation. Any industry that prioritizes safety and environmental sustainability greatly benefits from a well-implemented HSE plan.

- How frequently should an HSE plan be updated? Regular updates are crucial to keep HSE plans relevant. Aim for annual reviews at a minimum, but updates should also occur whenever there are significant changes in operations, regulations, or identified risks.

- Are there software tools available for managing HSE plans? Yes, there are numerous software solutions tailored for HSE management. These tools assist in risk assessment, incident reporting, training management, and overall plan monitoring. They streamline processes and enhance efficiency.

- How do HSE plans impact an organization’s bottom line? Effective HSE plans positively impact the bottom line by reducing costs associated with accidents, downtime, insurance premiums, and legal liabilities. Moreover, they enhance productivity, employee morale, and brand reputation.

- What role does employee participation play in HSE plan success? Employee participation is pivotal. Engaged employees contribute ideas, adhere to safety protocols, and actively identify and report potential risks. Their involvement fosters a culture of safety, crucial for the success of HSE plans.