Lockout and Tagout – LOTO 5 Minute Safety Talk

Good morning team,

Today we’re going to talk about a life-saving procedure that should never be skipped—Lockout/Tagout, or LOTO for short.

LOTO is used to make sure that machines are completely shut off and can’t be turned on again while maintenance or repairs are being done. It’s all about control of hazardous energy—electric, mechanical, hydraulic, pneumatic, chemical, and even thermal.

Skipping LOTO can lead to severe injuries, amputations, or fatalities. That’s why we follow this procedure every single time. Let’s take the next five minutes to go over the basics and make sure we all understand how LOTO protects us.

Why Lockout/Tagout Is Critical

Imagine you’re fixing a machine and someone unknowingly turns it on. That moment of miscommunication can change your life forever.

LOTO helps prevent:

- Unexpected machine startups

- Release of stored energy

- Contact with moving parts

- Exposure to hazardous fluids, gases, or electricity

According to OSHA, failure to control hazardous energy is a leading cause of workplace injuries.

Types of Hazardous Energy

- Electrical – Live wires, energized circuits

- Mechanical – Springs, flywheels, gears

- Hydraulic – Pressurized fluid systems

- Pneumatic – Compressed air or gas

- Thermal – Hot surfaces, steam

- Chemical – Stored chemicals or vapors

LOTO ensures all these energy sources are safely isolated.

What Is Lockout/Tagout?

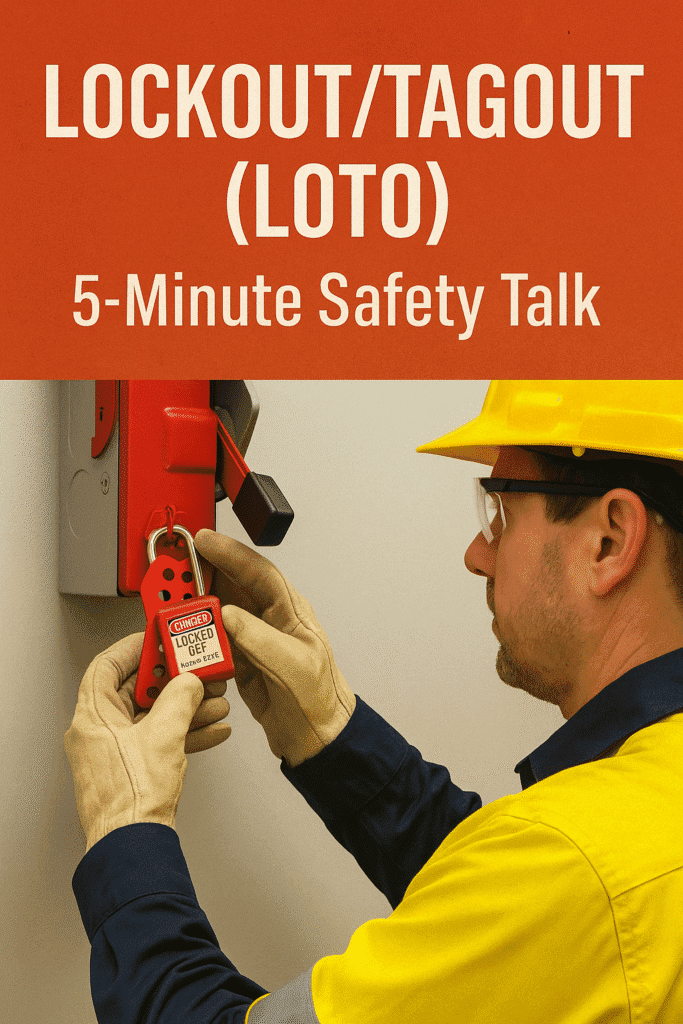

- Lockout involves placing a physical lock on the energy-isolating device (like a switch or valve) to prevent it from being turned back on.

- Tagout involves placing a warning tag with the worker’s name, date, and reason for lockout.

Together, they send a clear message: Do not operate. Someone is working.

When Should You Use LOTO?

Apply LOTO anytime:

- Performing maintenance, repairs, or cleaning

- Removing or bypassing safety devices

- Placing hands near moving parts

- Clearing jams or performing adjustments

- Working on electrical or pressurized systems

If there’s a chance of energy causing harm, use LOTO.

Basic Steps of the LOTO Procedure

- Prepare for Shutdown – Identify energy sources and procedures

- Notify Affected Employees – Let coworkers know maintenance is starting

- Shutdown Equipment – Turn off machine using normal procedure

- Isolate Energy Sources – Turn off switches, valves, breakers

- Apply Lock and Tag – Use lock and fill out tag with clear info

- Release Stored Energy – Drain lines, bleed pressure, block movement

- Verify Zero Energy – Try to start the machine to confirm it’s de-energized

Never skip verification—it could save your life.

Restoring Equipment After Maintenance

When the job is done:

- Ensure all tools are removed

- Replace guards and safety devices

- Notify coworkers

- Remove lock and tag (only by the person who applied it)

- Restore energy sources

- Start equipment safely

Never allow someone else to remove your lock—that’s your personal safety guarantee.

Common Mistakes to Avoid

- Not following all steps in the LOTO procedure

- Using tags without physical locks

- Forgetting to notify others before starting

- Leaving residual energy (like pressure or charge)

- Using someone else’s lock

- Removing locks without authorization

LOTO isn’t just paperwork—it’s personal protection.

Real-Life Example

A worker began servicing a conveyor belt without applying LOTO. Another employee turned it on from the control panel, unaware someone was inside. The result? Crushed fingers and permanent disability.

All because one step was skipped.

LOTO Safety Checklist

- Have I identified all energy sources?

- Did I shut down and isolate them properly?

- Is my lock and tag clearly placed and labeled?

- Have I verified zero energy?

- Did I notify my team?

If you can’t check “yes” to all—stop and fix it.

Your Responsibility

- Follow LOTO procedures every time

- Use your personal lock and tag—never share

- Speak up if you see LOTO being skipped or rushed

- Stay trained and updated on your site’s LOTO policy

Your lock is your life—take it seriously.

Conclusion

LOTO isn’t optional. It’s a proven system that prevents serious injuries and saves lives. Every piece of equipment, every job, every time—you need to Lock it out and Tag it out before you begin work.

So remember:

- Identify hazards

- Lock and tag every energy source

- Verify zero energy

- Stay alert

- Follow procedures

Because the one thing you can’t lock out is regret.

Chemical Handling 5 Minute Safety Talk

Hot Work Safety 5 Minute Safety Talk

Working at Height 5 Minute Safety Talk

Safe Lifting Techniques 5 Minute Safety Talk

Slips Trips and Falls 5 Minute Safety Talk

5 Unique FAQs

Q1: Can I just tag a machine instead of locking it out?

No. Tagout alone doesn’t physically prevent startup. Always lock when possible.

Q2: Can a supervisor remove someone else’s lock?

Only in emergencies and with written procedures—and never without notifying the lock owner.

Q3: Do I need LOTO if I’m only doing a quick task?

Yes. Time doesn’t reduce risk. If you’re exposed to energy, use LOTO.

Q4: What if my lock key gets lost?

Report it immediately. Follow your company’s procedure for safe lock removal and replacement.

Q5: Who needs LOTO training?

All authorized employees who perform service or maintenance must receive formal LOTO training.