Machine Safety Rules

Machine Safety Rules : To improve machine safety, it is very important for manufacturers to reduce the risks of accidents, for this it is very important to pay attention to machine safety which is very important for the safety of the workers.

However, the cost of a comprehensive security policy can outweigh these benefits. Here are 3 tips for machine safety, if followed, then the accident caused by the machine can be prevented.

1. Consider Each Machine Individually

All the machines running inside the organization, each machine needs to be considered individually. While installing a new machine the plant manager should carefully consider how to be safe while using this machine and not face ergonomics problem.

While installing the machine, the plant manager should conduct a risk assessment, which has determined whether the emissions generated by the operation of the machine are polluting the environment. If the machine is being operated inside a closed space, then special attention has to be given to it whether it is not affecting the ventilation.

Different types of machines in Plant Manager require different safety considerations. Whatever the manufacturers are, they not only have to ensure that their machines are designed on the basis of relevant standards, but they also have to see whether they are working as per their design or not.

There may be some machines or equipment that may have to operate in an explosive environment or may be operated in a place where it may come into contact with a hazardous substance.

Therefore, the regulation made for the machine has to be followed, which is very important for the employees from the point of view of convenience and safety.

2. Trained Personnel

For machine safety and operator safety, a complete understanding about the operation of the machine is very important. Operating the machine with half-incomplete information can cause injury. Therefore, there is a safety department that provides detailed training to the operator for operating the machine, which helps in operating the machine safely.

When the machine is being operated, it is mandatory for the operator to wear safety equipment (PPE) himself, because after the accident or acts as a barrier and plays an important role in avoiding injury to the operator.

It is also necessary to maintain all the machines that are operated at the workplace and a checklist is provided to ensure that the machine is in good condition or not.

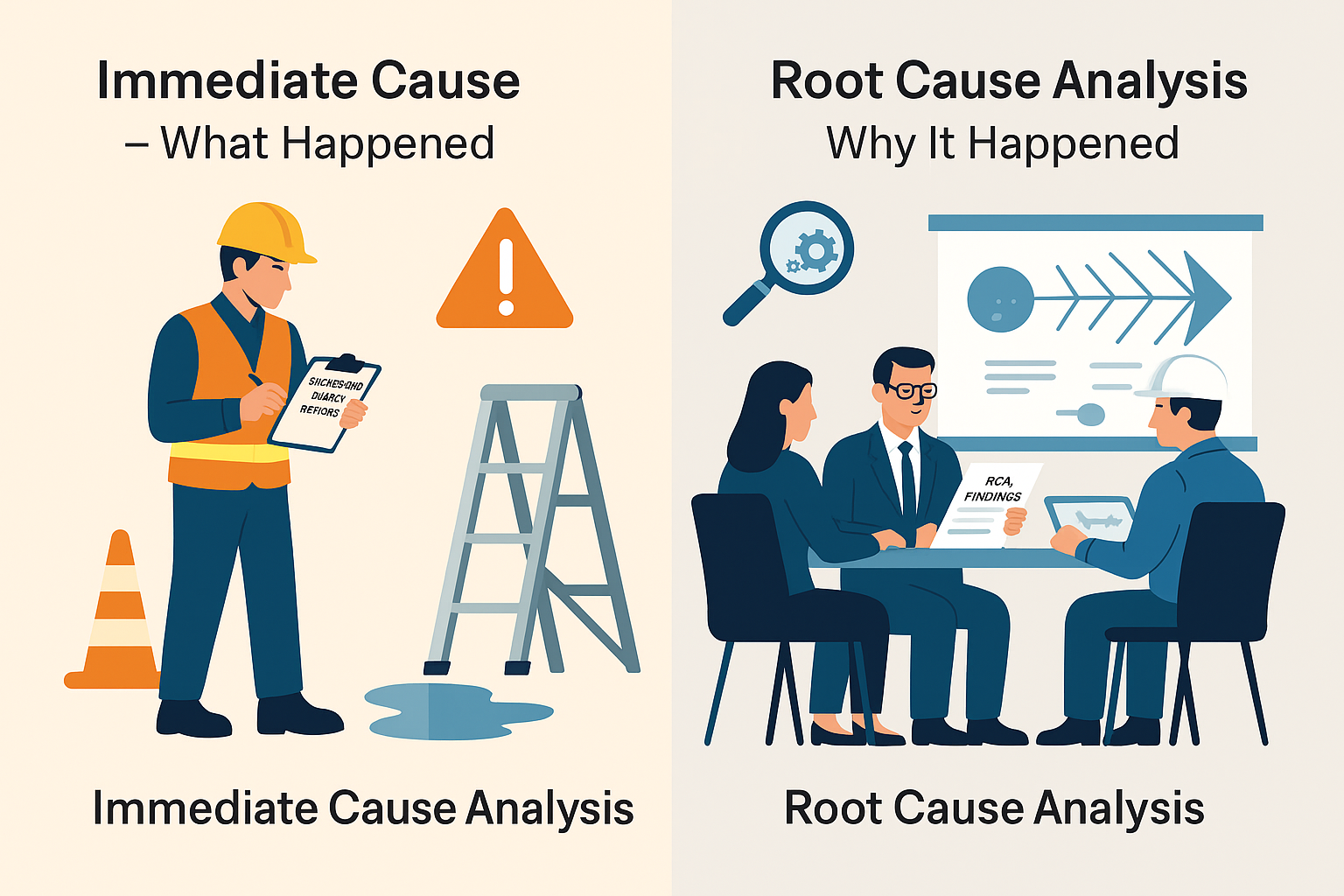

Wherever the machine is to be operated, there should be such a person that if there is any kind of confusion related to the operation or the machine, then he can be asked. It helps in removing the risk arising by human error, which also plays a very important role for machine safety.

3. Connect

Workplace safety is essential to reduce the risk of fatal and non-fatal accidents. It benefits the employees as well as the organization directly and indirectly. But adding systems to improve productivity can be an added bonus.

If we want to improve the performance of the equipment from the point of view of safety, then connecting it to the sensor is a good option to make the safety of the workplace more secure.

By using technology like Internet of Things, management can collect real information about its equipment and it can also analyze it. If it is not available at workplace then it is possible through internet of things.

Such features can not only help in preventing accidents but also can easily identify problems with the machinery, which is important for the safety of the operator.

The machines that are connected may measure the device’s measurement bar to warn of any risks of overheating, which could lead to a breakdown. And if a serious threat is found, the personnel can be evacuated from there.

If any part of the machine is broken, the manager can be forced to replace it. Because after providing a facility like IoT, the manager cannot lie that he was not aware of it.

This feature provides full support to the maintenance team in not making mistakes or can be said to warn them not to be careless.