Root Cause Analysis vs Immediate Cause Analysis: Key Differences Explained for Safety Professionals

When an accident or incident occurs, every safety professional’s goal is the same — to prevent it from happening again.

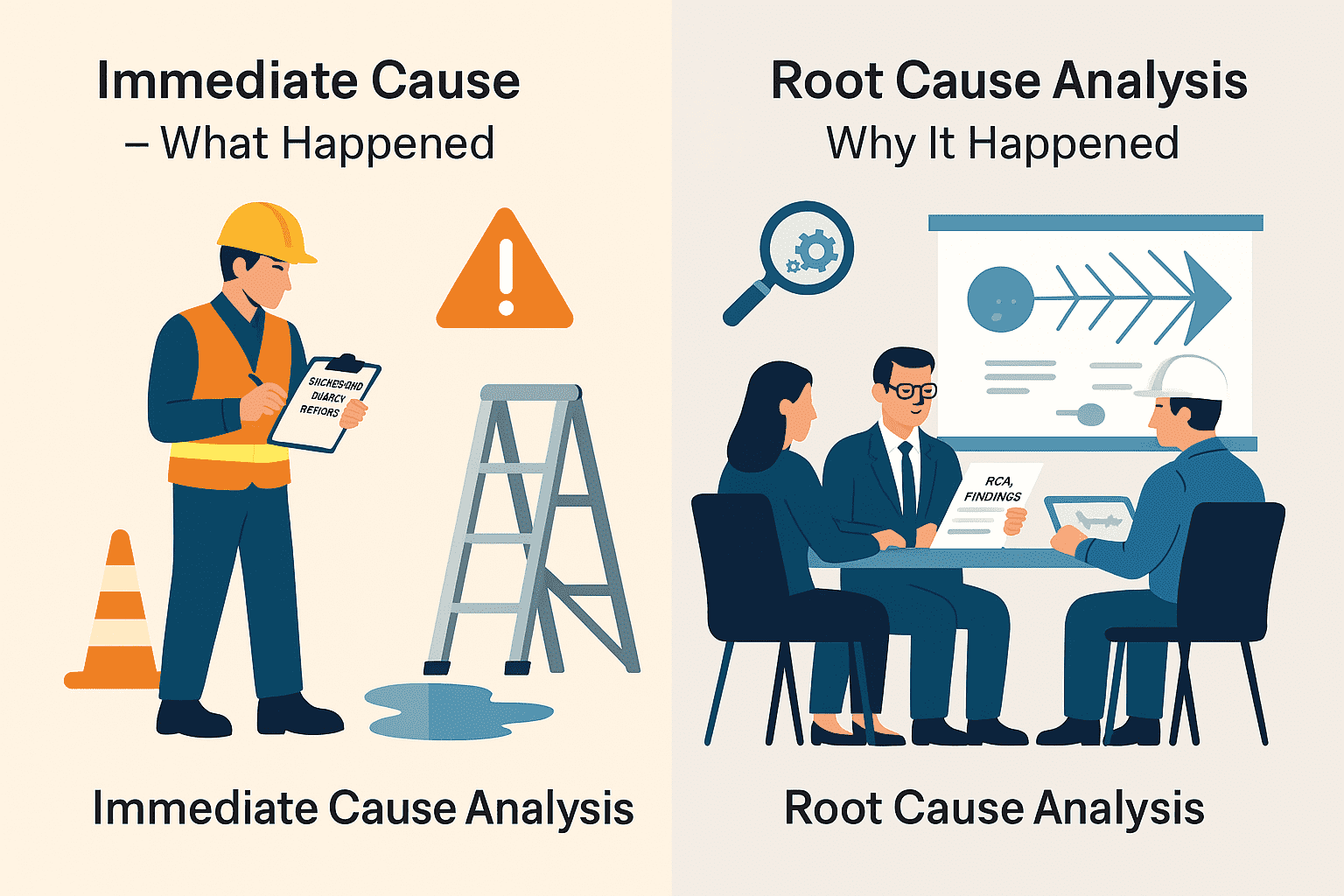

To do this, organizations perform two critical types of analysis: Immediate Cause Analysis (ICA) and Root Cause Analysis (RCA).

While both sound similar, they are not the same.

- Immediate Cause Analysis identifies what happened and why it happened right now.

- Root Cause Analysis digs deeper to uncover why the underlying system allowed it to happen in the first place.

This article explores the difference, purpose, methods, and practical examples of both analyses — helping you build a more effective safety investigation process.

What is an Immediate Cause Analysis (ICA)?

Definition

An Immediate Cause Analysis focuses on identifying the direct, visible, and surface-level factors that led to an incident or unsafe event.

It answers the question: “What unsafe act or unsafe condition caused the incident?”

These are typically human errors or environmental factors that directly contributed to the event.

Examples of Immediate Causes

- Worker failed to wear PPE.

- Machine guard was missing.

- Slippery floor due to oil spill.

- Electrical wire exposed.

- Incorrect tool used for the job.

Purpose

- Identify direct hazards or violations.

- Implement quick corrective actions.

- Prevent recurrence in the short term.

When to Use

Immediately after an incident — during initial investigation or site inspection.

What is a Root Cause Analysis (RCA)?

Definition

A Root Cause Analysis is a systematic and deeper investigation that identifies the underlying reasons behind an incident.

It focuses on the systemic failures that allowed the immediate causes to exist.

It answers the question: “Why did the unsafe act or condition occur in the first place?”

Purpose

- Discover systemic or management-level weaknesses.

- Prevent recurrence in the long term.

- Strengthen organizational safety culture.

Examples of Root Causes

- Inadequate safety training.

- Poor supervision or monitoring.

- Lack of maintenance procedures.

- Weak safety policy or enforcement.

- Ineffective communication between departments.

When to Use

After gathering facts and evidence during an investigation — typically within 24–48 hours after an incident.

Key Differences Between Immediate Cause Analysis and Root Cause Analysis

| Aspect | Immediate Cause Analysis (ICA) | Root Cause Analysis (RCA) |

|---|---|---|

| Definition | Identifies direct, surface-level reasons for an incident | Identifies deep, underlying reasons that allowed the incident |

| Focus | Unsafe acts and unsafe conditions | Systemic and organizational failures |

| Objective | Prevent recurrence in the short term | Prevent recurrence in the long term |

| Level of Investigation | Basic (operational) | Advanced (management/systemic) |

| Examples | Worker not wearing PPE, oil spill on floor | Lack of PPE training, poor maintenance policy |

| Timing | Conducted immediately after the incident | Conducted after data collection and analysis |

| Outcome | Quick corrective actions | Long-term preventive measures |

| Responsibility | Supervisor/Safety Officer | Investigation team/Management |

| Tools Used | Checklists, observation | 5 Whys, Fishbone (Ishikawa), Fault Tree Analysis |

How Immediate Cause and Root Cause Relate

Both analyses are connected stages of the same investigation process:

- Incident Occurs

↓ - Identify Immediate Causes (unsafe acts and conditions)

↓ - Conduct Root Cause Analysis to find underlying failures

↓ - Implement Corrective and Preventive Actions

↓ - Monitor and Review for effectiveness

In short: “Immediate cause analysis treats the symptoms — root cause analysis cures the disease.”

Example Scenario: Worker Falls from Height

Incident:

A worker falls from scaffolding and suffers a fracture.

| Type | Finding |

|---|---|

| Immediate Cause | The worker was not wearing a safety harness. |

| Root Cause | The supervisor failed to enforce PPE use and no safety training was provided. |

| Underlying System Failure | Weak safety culture and absence of PPE compliance policy. |

Corrective vs Preventive Actions

| Action Type | Example |

|---|---|

| Corrective (Immediate Cause) | Issue harnesses and ensure workers use them. |

| Preventive (Root Cause) | Conduct training, enforce PPE policy, include safety checks in supervision plans. |

Example Scenario: Machine Fire in Workshop

| Immediate Cause | Overheated motor due to dust clogging. |

| Root Cause | Inadequate preventive maintenance schedule. |

| Underlying Failure | Lack of asset management system and budget for maintenance. |

This example shows how addressing only the immediate cause (cleaning dust) won’t prevent future fires — fixing the system weakness (maintenance program) will.

Methods for Root Cause Analysis

1. 5 Whys Technique

A simple and effective method where you keep asking “Why?” until you find the true root cause.

Example:

Problem: Worker slipped on an oily floor.

- Why did the worker slip? → Because there was oil on the floor.

- Why was there oil on the floor? → Because a pipe was leaking.

- Why was the pipe leaking? → Because the seal was worn out.

- Why wasn’t the seal replaced? → Because there’s no preventive maintenance schedule.

- Why isn’t there a schedule? → Because maintenance policy is outdated.

Root Cause: Inadequate maintenance management.

2. Fishbone Diagram (Ishikawa)

Visually categorizes causes into areas like:

- Man (People)

- Machine (Equipment)

- Method (Procedure)

- Material

- Environment

- Management

This helps identify multiple contributing factors for complex incidents.

3. Fault Tree Analysis

Used for detailed, system-based analysis to find how combinations of failures lead to an incident.

Benefits of Immediate Cause and Root Cause Analysis

Immediate Cause Analysis

- Quick hazard identification.

- Rapid corrective action.

- Minimizes downtime.

- Improves day-to-day safety compliance.

Root Cause Analysis

- Eliminates recurrence of similar events.

- Improves safety culture and accountability.

- Strengthens systems and management.

- Supports ISO 45001 and OSHA compliance.

Integration in a Safety Management System

| ISO 45001 Clause | Relevance |

|---|---|

| 10.2 – Incident Investigation | Immediate Cause Analysis |

| 10.2 – Corrective Action | Root Cause Analysis |

| 10.3 – Continuous Improvement | Monitoring and Review |

Both analyses together create a cycle of learning and improvement that ensures safety maturity.

Common Mistakes in Cause Analysis

Stopping investigation at immediate causes only.

Blaming individuals instead of the system.

Ignoring near misses (valuable learning events).

Failing to implement or monitor corrective actions.

Lack of training in RCA tools.

“If you blame people, you fix nothing. If you fix systems, you fix everything.”

Summary Table: Root Cause Analysis vs Immediate Cause Analysis

| Parameter | Immediate Cause Analysis | Root Cause Analysis |

|---|---|---|

| Focus | What happened | Why it happened |

| Level | Surface | Deep/Systemic |

| Goal | Correct immediate issues | Prevent future recurrence |

| Timeframe | Short-term | Long-term |

| Tools | Checklists, observations | 5 Whys, Fishbone Diagram |

| Responsibility | Supervisor/Safety Officer | Investigation Team/Management |

| Example | Worker didn’t wear PPE | No PPE training or enforcement policy |

Conclusion

Both Immediate Cause Analysis and Root Cause Analysis are essential for a complete and effective incident investigation.

- Immediate Cause Analysis helps you react quickly to eliminate visible hazards.

- Root Cause Analysis ensures you prevent recurrence by fixing system-level weaknesses.

“Immediate causes show what went wrong; root causes reveal why it was allowed to go wrong.”

By combining both approaches, organizations not only fix problems but build safer, smarter, and stronger safety systems.

For checklist and templates visit The HSE Tools.

Safety Observation vs Near Miss Report

Advanced Techniques for Incident Investigation in Oil & Gas Industry

5 Construction Site Near-Miss Case Studies

Factory Accident Examples: What Went Wrong?

FAQs

Q1. Can an investigation end after finding the immediate cause?

No. Always continue to identify the root cause for long-term prevention.

Q2. Who performs root cause analysis?

Trained safety professionals or an investigation team including management and subject matter experts.

Q3. What tools are best for RCA?

5 Whys, Fishbone Diagram, Fault Tree Analysis, and Pareto Analysis.

Q4. How soon should immediate cause analysis start after an incident?

Immediately — within minutes to hours, while the site and evidence are still intact.

Q5. What’s the ultimate goal of both analyses?

To eliminate hazards, strengthen systems, and prevent similar incidents from happening again.