Web Belt Sling Working Load Limit (WLL)

Introduction

Web Belt Sling Working Load Limit (WLL) : Web belt slings are indispensable tools in various industries, providing an effective means of lifting and transporting heavy loads. However, understanding the Working Load Limit (WLL) of these slings is crucial to ensure safety and efficiency. In this article, we will explore what web belt slings are, delve into the concept of WLL, and discuss the factors that affect it. We will also highlight the importance of knowing WLL, explain how to calculate it, and provide safety guidelines for their usage.

What is a Web Belt Sling?

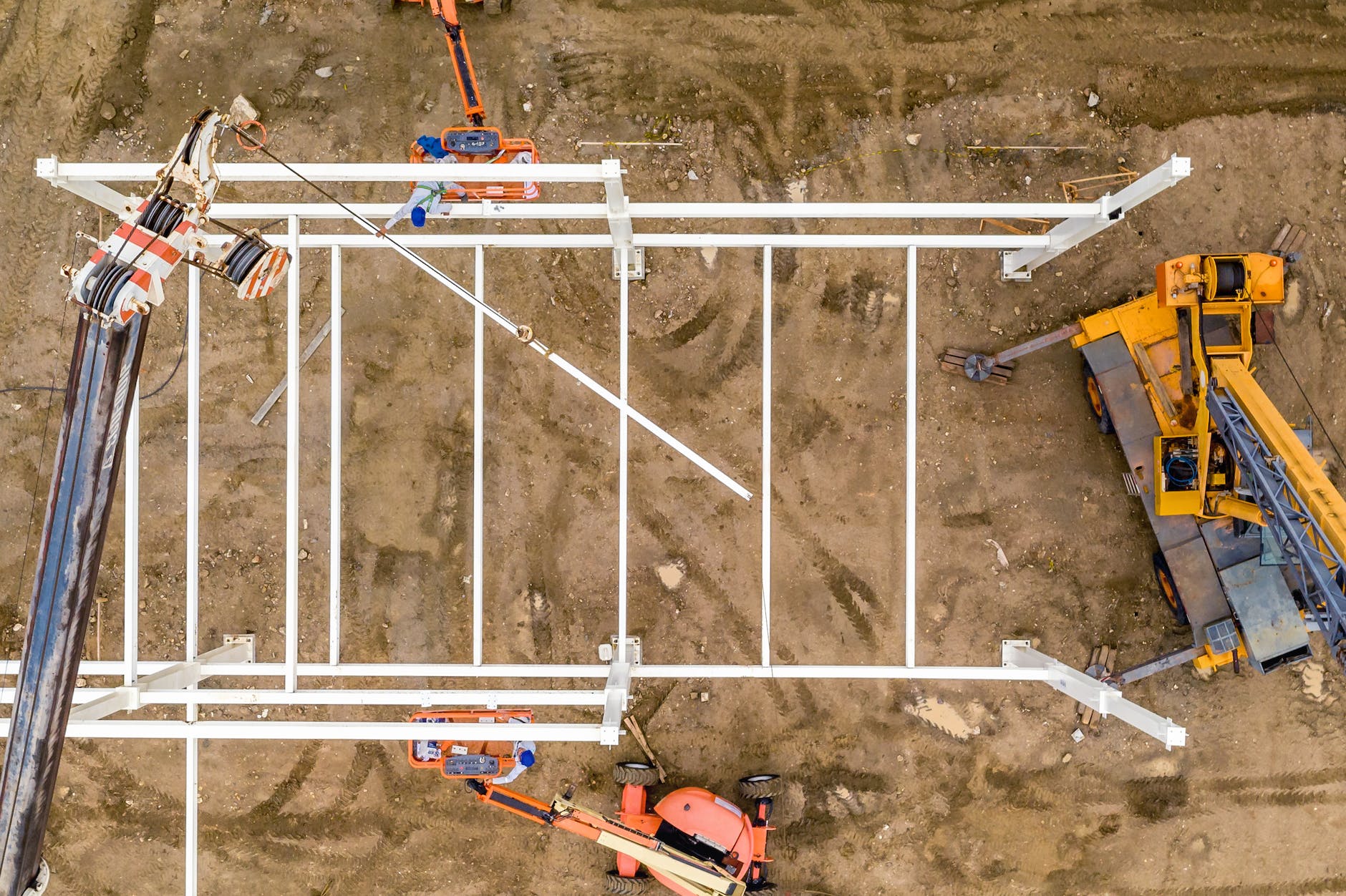

A web belt sling is a versatile piece of equipment designed for lifting, rigging, and securing heavy loads. It consists of a woven webbing made from materials like nylon, polyester, or polypropylene, which is wrapped and stitched to form a loop. These slings are used in construction, manufacturing, and various industrial settings.

Understanding Working Load Limit (WLL)

The Working Load Limit (WLL) is the maximum weight that a web belt sling can safely handle. Exceeding this limit can lead to catastrophic failures, endangering both personnel and the load being lifted. WLL is typically expressed in pounds or kilograms and is marked on the sling for easy identification.

Factors Affecting WLL

Several factors influence the WLL of a web belt sling:

- Material: The type of material used in the sling affects its strength and, consequently, its WLL.

- Configuration: How the sling is constructed, whether it’s a single or double-ply, impacts its capacity.

- Angle of Use: The angle at which the sling is used affects its load-bearing capacity. As the angle increases, the WLL decreases.

- Temperature: Extreme temperatures can weaken the material of the sling, reducing its WLL.

- Abrasion and Damage: Any damage to the sling, such as cuts or fraying, can significantly decrease its WLL.

Importance of Knowing WLL

Knowing the WLL of a web belt sling is essential for preventing accidents and ensuring the safety of personnel. Using a sling with a lower WLL than required can lead to overloading, resulting in sling failure and possible injuries.

Calculating WLL

To calculate the WLL for a specific lifting scenario, you can use the following formula:

WLL = Material Strength x Configuration Factor x Angle Factor x Temperature Factor x Safety Factor

Scenario: Lifting Concrete Blocks

John is a construction worker tasked with lifting concrete blocks onto the 5th floor of a building under construction. He wants to ensure the safety of the lifting operation by calculating the WLL for the web belt sling he will be using.

Concrete Block Specifications

John knows that the concrete blocks vary in weight and size. In this scenario, he has to lift a concrete block that weighs 3,000 pounds.

Factors for Calculating WLL

To calculate the WLL for the web belt sling, John considers the following factors:

- Material Strength: He checks the web belt sling and finds that it is made from high-strength nylon, which has a known material strength of 9,000 pounds.

- Configuration Factor: The web belt sling he is using is a double-ply sling, which has a configuration factor of 2.

- Angle of Use: John plans to use the sling at a 60-degree angle. He checks the angle factor table, which indicates that the angle factor for a 60-degree angle is 0.866.

- Temperature Factor: The construction site is at a standard temperature, so the temperature factor remains 1.

- Safety Factor: John follows the safety guidelines and selects a safety factor of 5, as it’s a critical lifting operation.

Calculating the WLL

Now, John calculates the WLL using the formula:

WLL = Material Strength x Configuration Factor x Angle Factor x Temperature Factor x Safety Factor

WLL = 9,000 pounds (Material Strength) x 2 (Configuration Factor) x 0.866 (Angle Factor) x 1 (Temperature Factor) x 5 (Safety Factor)

WLL = 9,000 x 2 x 0.866 x 1 x 5

WLL = 77,985 pounds

Conclusion

In this scenario, John calculates the Working Load Limit (WLL) for the web belt sling he will be using to lift a concrete block. The calculated WLL is 77,985 pounds, which means that he can safely lift the 3,000-pound concrete block without exceeding the sling’s capacity. By performing this calculation and adhering to safety measures, John ensures a safe and efficient lifting operation at the construction site.

Safety Measures

When using web belt slings, several safety measures should be adhered to:

- Always inspect the sling for damage or wear before each use.

- Follow the manufacturer’s guidelines for usage and maintenance.

- Ensure the load is evenly distributed across the sling.

- Use appropriate hardware, such as shackles or hooks, with the sling.

- Avoid shock loading or sudden jerks when lifting.

- Never exceed the marked WLL of the sling.

Types of Web Belt Slings

There are various types of web belt slings available, including endless slings, flat eye and eye slings, and round slings. Each type is designed for specific applications and has its unique advantages.

Inspecting and Maintaining Web Belt Slings

Regular inspection and maintenance are crucial to ensure the reliability of web belt slings. Inspect for signs of wear, cuts, and abrasions, and replace damaged slings immediately.

Proper Usage

Proper usage of web belt slings involves understanding the load’s weight, shape, and center of gravity. The correct attachment points and angles are essential for safe lifting.

Applications of Web Belt Slings

Web belt slings find applications in a wide range of industries, including construction, manufacturing, shipping, and offshore operations. They are ideal for lifting heavy machinery, steel beams, and more.

Advantages of Web Belt Slings

The advantages of using web belt slings include their flexibility, lightweight design, and ease of use. They are also less likely to cause damage to delicate loads.

Limitations of Web Belt Slings

Despite their versatility, web belt slings have limitations. They may not be suitable for extremely high-temperature environments or for lifting abrasive materials.

Regulations and Standards

Various regulations and industry standards govern the use of web belt slings. Complying with these standards is essential for safety and legal reasons.

Conclusion

In conclusion, web belt slings are invaluable tools for lifting heavy loads in diverse industries. Understanding the Working Load Limit (WLL) and adhering to safety measures are crucial for their safe and efficient usage. By following guidelines and standards, we can ensure that web belt slings continue to play a vital role in our industrial processes.

Crane Lifting Safety Toolbox Talk Meeting

Lost Time Incident Rate and How To Calculate LTI

How To Become a Lifting Supervisor

How To Become a Crane Operator

FAQs

1. What materials are commonly used in web belt slings? Web belt slings are typically made from materials like nylon, polyester, or polypropylene.

2. How do I calculate the Working Load Limit (WLL) for a specific lifting scenario? The WLL can be calculated using a formula that considers material strength, configuration, angle of use, temperature, and safety factors.

3. Are there specific guidelines for inspecting and maintaining web belt slings? Yes, manufacturers provide guidelines for inspecting and maintaining web belt slings, which should be followed closely.

4. What are the advantages of using web belt slings over other lifting equipment? Web belt slings offer advantages such as flexibility, lightweight design, and reduced risk of damaging delicate loads.

5. Are there industry standards for the use of web belt slings? Yes, there are industry standards and regulations that govern the use of web belt slings, ensuring safety and compliance.