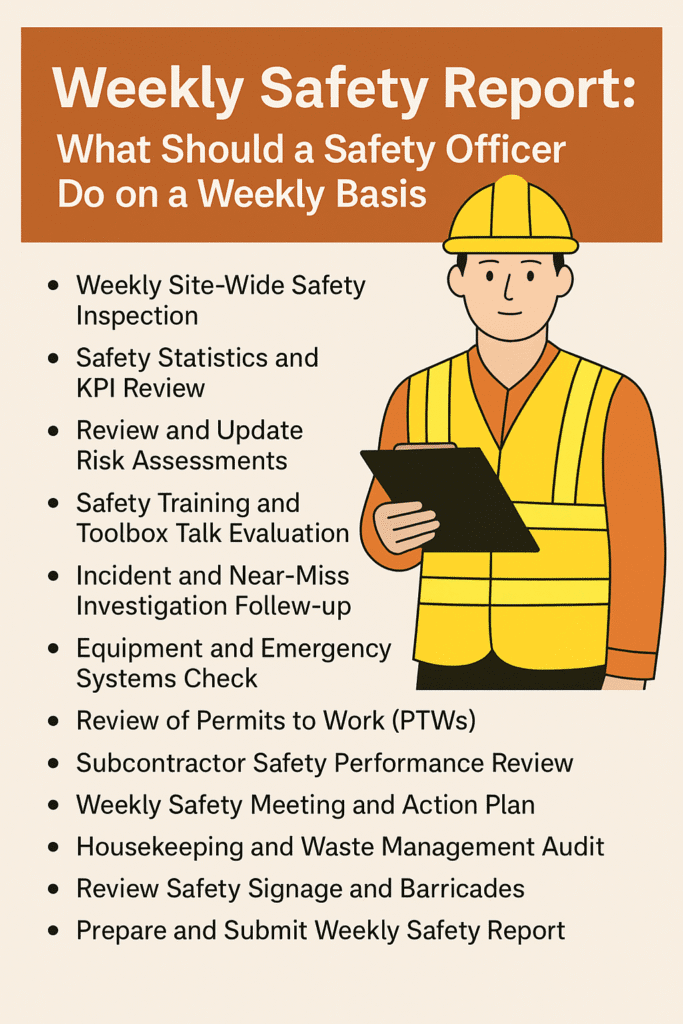

Weekly Safety Report: What Should a Safety Officer Do on a Weekly Basis

A safe workplace doesn’t happen by accident—it’s the result of continuous effort, planning, and review. While daily checks keep hazards in check, a Weekly Safety Report provides a broader view of ongoing safety performance, trends, and compliance. It’s a strategic document that ensures safety management systems are functioning effectively and that workers are protected consistently over time.

As a Safety Officer, your weekly responsibilities are just as critical as your daily tasks. This article outlines the essential activities you must perform every week to maintain workplace safety and regulatory compliance.

What is a Weekly Safety Report?

A Weekly Safety Report is a detailed summary of all safety-related activities, inspections, incidents, and improvements carried out during the week. It provides a snapshot of the safety health of the site or project and helps the management team identify areas that require intervention or improvement.

Why Weekly Safety Reviews Are Important

- Identifies recurring hazards

- Tracks safety performance KPIs

- Highlights gaps in compliance

- Enables early corrective actions

- Enhances site-wide accountability

- Ensures continued legal compliance

Key Activities for Safety Officers – Weekly Basis

To prepare an effective weekly safety report, safety officers must focus on both preventive measures and performance analysis. Here’s what to do every week:

1. Weekly Site-Wide Safety Inspection

Conduct a comprehensive walkthrough of the entire site or facility:

- Check high-risk zones

- Inspect scaffoldings, ladders, electrical panels, etc.

- Validate that controls from risk assessments are implemented

- Involve supervisors and team leads

Document findings using a standard inspection checklist.

2. Safety Statistics and KPI Review

Analyze:

- Number of safety observations

- Near-miss and incident counts

- Toolbox Talk attendance

- Safety training conducted

- PTW compliance percentage

Compare against safety targets and identify trends.

3. Review and Update Risk Assessments

- Reassess high-risk activities

- Update risk control measures if conditions have changed

- Check if new equipment, processes, or personnel require new assessments

Involve relevant team members in the review process.

4. Safety Training and Toolbox Talk Evaluation

- Review which topics were covered in daily toolbox talks

- Identify knowledge gaps or recurring unsafe behaviors

- Plan for next week’s sessions based on current site conditions

Also, schedule refresher or specialized training if needed.

5. Incident and Near-Miss Investigation Follow-up

- Review the status of any ongoing incident/near-miss investigations

- Ensure that root cause analysis is completed

- Verify that corrective and preventive actions are closed out

Record the implementation status in the weekly report.

6. Equipment and Emergency Systems Check

- Inspect fire extinguishers, spill kits, alarms, eyewash stations

- Ensure calibration of gas detectors and other instruments

- Confirm availability of emergency PPE and first aid kits

Include expiry dates and inspection history in your logs.

7. Review of Permits to Work (PTWs)

- Check permit issuance logs for the week

- Verify PTW closure and handover records

- Audit high-risk permits like hot work, confined space, and excavation

Flag any non-compliance or permit misuse.

8. Subcontractor Safety Performance Review

- Evaluate the safety performance of all subcontractors

- Review their toolbox talks, incident logs, and manpower PPE compliance

- Give feedback and require action plans if necessary

Ensure alignment with project/client safety standards.

9. Weekly Safety Meeting and Action Plan

- Hold a formal Weekly Safety Review Meeting

- Discuss:

- Incidents

- Observations

- Outstanding issues

- Corrective actions

- Upcoming hazards

- Prepare a safety action plan for the following week

Record meeting minutes with attendance logs.

10. Housekeeping and Waste Management Audit

- Check for:

- Waste accumulation

- Open chemical containers

- Poorly stored tools and equipment

- Blocked access or emergency exits

Assign housekeeping duties and deadlines.

11. Review Safety Signage and Barricades

- Replace faded, damaged, or missing signs

- Confirm barricades are placed where necessary

- Evaluate if temporary signs from earlier in the week are still relevant

This ensures visual safety communication is always current.

12. Prepare and Submit Weekly Safety Report

Your final task of the week is compiling and submitting the report. It should include:

- Overview of weekly activities

- Number of inspections

- Training and toolbox talks

- Incidents and follow-up

- Photos and evidence

- Action items and recommendations

Submit it to your HSE Manager, Site Manager, or Project Team.

Tips for a Comprehensive Weekly Safety Report

- Use graphs/charts for data clarity

- Include photo evidence

- Categorize observations by department/area

- Provide SMART action plans (Specific, Measurable, Achievable, Relevant, Time-bound)

- Add a summary at the beginning for quick reference

Conclusion

Being a safety officer is not just about reacting to incidents—it’s about planning, leading, and driving safety culture. A Weekly Safety Report helps you go beyond surface-level observations and look at the bigger picture. When done right, it transforms data into decisions and hazards into opportunities for improvement.

By consistently executing these weekly responsibilities, you not only maintain compliance—you save lives.

Onsite Emergency Plan under Factories Act, 1948

Off-Site Emergency Plan | Free Download

ON-SITE EMERGENCY PLAN | Free Download

Top 10 Essential Safety Documents Every Company Needs

FAQs

Q1. Who prepares the weekly safety report?

Usually, the Safety Officer or HSE Engineer prepares the weekly report and submits it to the Safety Manager or Project Manager.

Q2. How long should a weekly safety report be kept?

Most companies retain reports for 3–5 years for audit and legal compliance purposes.

Q3. What’s the difference between a daily and weekly safety report?

A daily report focuses on immediate observations and incidents, while a weekly report provides an overall analysis, trend tracking, and strategic planning.

Q4. Can I use software to prepare my weekly report?

Yes. Tools like MS Excel, iAuditor, Safetymint, or customized HSE dashboards can help you track, visualize, and present data more effectively.

Q5. Should I include positive observations in my report?

Absolutely. Highlighting good practices boosts morale and reinforces safe behavior.