HSE Plan for Oil and Gas Companies

Introduction to HSE Plan for Oil and Gas Companies

In the dynamic realm of the oil and gas industry, ensuring Health, Safety, and Environment (HSE) measures are paramount. An HSE plan serves as a comprehensive blueprint, safeguarding operations, personnel, and the environment. Let’s delve into the core components and significance of crafting a robust HSE plan.

Importance of HSE in the Oil and Gas Industry

Safety and environmental concerns are intrinsic to the oil and gas sector. HSE plans mitigate risks, fostering a secure working environment while aligning with environmental regulations.

Overview of HSE Plans

HSE plans encompass a spectrum of strategies, policies, and protocols designed to prevent accidents, manage risks, and promote responsible environmental practices.

Components of an HSE Plan

Risk Assessment and Management

Thorough risk assessments identify potential hazards, enabling proactive risk management strategies.

Safety Protocols and Procedures

Defined safety protocols ensure adherence to industry standards and best practices.

Emergency Response Plans

Preparedness is key. Well-defined emergency response plans mitigate the impact of unforeseen incidents.

Creating a Health, Safety, and Environment (HSE) plan for an oil and gas company involves a comprehensive strategy to ensure the well-being of workers, protect the environment, and comply with regulations. Here's a structured outline for such a plan:1. Introduction

- Brief overview of the company’s commitment to HSE.

- Importance of HSE in the oil and gas industry.

2. Policy Statement

- Clear, concise statement outlining the company’s commitment to HSE.

- Emphasis on safety, environmental protection, and health of employees and communities.

3. Organizational Structure

- HSE management team roles and responsibilities.

- Reporting lines and communication channels for HSE matters.

4. Risk Assessment

- Identification of potential hazards and risks associated with operations.

- Evaluation of risks and their potential impact on personnel, environment, and assets.

5. HSE Objectives and Targets

- Specific, measurable goals related to safety, health, and environmental protection.

- Targets for reducing incidents, injuries, and environmental impact.

6. Procedures and Processes

- Safety procedures for different operations (drilling, transportation, refining, etc.).

- Emergency response plans for various scenarios (spills, fires, accidents).

- Training programs for employees on safety protocols and environmental awareness.

7. Compliance and Regulations

- Ensure adherence to local and international HSE regulations.

- Regular audits and assessments to maintain compliance.

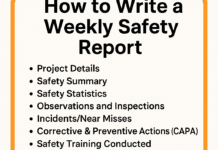

8. Monitoring and Measurement

- Implementation of systems to track HSE performance.

- Regular inspections, evaluations, and audits.

9. Incident Investigation and Reporting

- Protocols for reporting incidents, near misses, and accidents.

- Investigation procedures to identify root causes and prevent recurrence.

10. Continual Improvement

- Strategies for ongoing enhancement of HSE practices.

- Learning from incidents and implementing corrective actions.

11. Communication and Engagement

- Channels for HSE-related communication within the company.

- Engagement with stakeholders (employees, contractors, communities) on HSE matters.

12. Documentation and Record-Keeping

- Maintenance of accurate records related to HSE activities.

- Documenting improvements, audits, incidents, and compliance efforts.

13. Resources and Budget

- Allocation of resources (financial, personnel, technology) for HSE initiatives.

- Budget planning for HSE-related activities.

14. Review and Evaluation

- Scheduled reviews to assess the effectiveness of the HSE plan.

- Gathering feedback and making necessary adjustments for improvement.

Developing a robust HSE plan tailored to the oil and gas industry is crucial to ensuring the safety of personnel, protecting the environment, and maintaining operational efficiency.Implementing an HSE Plan

Employee Training and Awareness

Educating and engaging employees in HSE practices cultivates a safety-oriented culture.

Compliance with Regulations

Adherence to evolving regulations is crucial for sustained operational integrity.

Continuous Improvement Strategies

Adapting and evolving the HSE plan ensures its relevance and effectiveness over time.

Benefits of a Comprehensive HSE Plan

Reduced Accidents and Incidents

A well-executed HSE plan significantly lowers the occurrence of accidents and incidents.

Improved Reputation and Stakeholder Trust

Demonstrating commitment to HSE enhances trust among stakeholders and the community.

Cost Savings and Efficiency

Long-term cost savings result from decreased downtime and minimized resource wastage.

Challenges in Developing and Maintaining HSE Plans

Regulatory Changes

Navigating ever-evolving regulations demands continuous vigilance and adaptability.

Cultural Shifts

Instigating a culture where safety is ingrained may require substantial organizational shifts.

Resource Allocation

Allocating resources for HSE initiatives can pose challenges in budgeting and planning.

Conclusion

The HSE plan is the cornerstone of a responsible and sustainable oil and gas operation. Prioritizing the health and safety of personnel, the environment, and the community not only ensures regulatory compliance but also fosters trust and longevity in the industry.

HSE Plan for Construction Sites

Emergency Planning Ideas for Effective Disaster Management

Unique FAQs

- Why is an HSE plan crucial for oil and gas companies? An HSE plan safeguards against risks, enhances safety, ensures compliance, and promotes sustainable operations.

- How often should an HSE plan be reviewed and updated? Regular reviews, at least annually, are essential to adapt to changing regulations and industry best practices.

- Can small oil and gas companies benefit from an HSE plan? Absolutely. Regardless of size, implementing an HSE plan mitigates risks and establishes a safety-focused culture.

- What role does employee training play in an effective HSE plan? Employee training fosters awareness, engagement, and adherence to safety protocols, enhancing the plan’s effectiveness.

- Are there standard templates for HSE plans, or should they be customized? While templates exist, customizing HSE plans to fit the unique operational needs and risks of each company is crucial for maximum effectiveness.