IS 17893 Work Permit System – Code of Practice

In the ever-evolving landscape of workplace safety and regulatory compliance, the IS 17893 Work Permit System stands as a beacon of best practices for employers and employees alike. As we delve into the intricate details of this code of practice for 2023, we’ll explore its significance, key components, and how it contributes to fostering a safer and more efficient work environment.

Understanding the IS 17893 Work Permit System

What is the IS 17893 Work Permit System?

The IS 17893 Work Permit System is a comprehensive set of guidelines and procedures aimed at regulating and enhancing safety protocols in various industries. It encompasses a wide range of safety measures, covering everything from hazardous work environments to equipment operation.

Why Was It Introduced?

The introduction of the IS 17893 Work Permit System was driven by the need to standardize safety practices across different industries. It provides a framework for identifying, assessing, and mitigating risks associated with various work activities.

The Key Components of IS 17893 Work Permit System

1. Permit Types

The IS 17893 Work Permit System categorizes permits into different types based on the nature of work activities. These permit types are specifically designed to address the unique risks associated with each task. Common permit types include hot work permits, confined space entry permits, and electrical work permits. By categorizing permits, the system ensures that the appropriate safety measures are applied to each situation, reducing the likelihood of accidents.

2. Risk Assessment

A fundamental component of the IS 17893 system is the rigorous risk assessment process. Before any work activity begins, a comprehensive evaluation of potential hazards and risks is conducted. This involves identifying possible dangers, assessing their severity, and determining the likelihood of accidents. The goal is to proactively identify and mitigate risks, ensuring that all necessary precautions are in place to protect workers.

3. Training and Certification

To comply with the IS 17893 Work Permit System, employees involved in high-risk activities often need to undergo specialized training and certification. This training equips them with the knowledge and skills required to perform their tasks safely. Certification ensures that individuals are competent to operate specific equipment or perform particular tasks, reducing the chances of accidents due to incompetence.

4. Emergency Response

The IS 17893 system places significant emphasis on emergency response preparedness. It mandates that organizations have well-defined plans in place to respond effectively to unforeseen incidents. This includes having emergency contact information readily available, conducting regular drills, and ensuring that employees are aware of emergency procedures. By being prepared for emergencies, organizations can minimize the impact of accidents and injuries.

5. Permit Control and Authorization

Another crucial component of IS 17893 is the permit control and authorization process. This involves a structured workflow for requesting, approving, and issuing permits. Only authorized personnel, who have undergone the necessary training and certification, can approve and issue permits. This control ensures that work activities are only conducted when all safety requirements are met.

6. Monitoring and Auditing

Continuous monitoring and auditing are essential to ensure ongoing compliance with the IS 17893 Work Permit System. Regular inspections and audits are conducted to assess the effectiveness of safety measures and identify areas for improvement. This proactive approach helps organizations refine their safety procedures and make necessary adjustments to mitigate emerging risks.

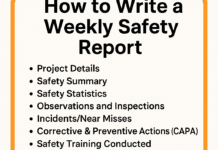

7. Documentation

Proper documentation is a cornerstone of IS 17893 compliance. Organizations are required to maintain comprehensive records of permits, risk assessments, safety training, and incident reports. This documentation serves as a trail of accountability, demonstrating that all necessary precautions were taken to ensure safety. It also helps in investigations and audits to confirm compliance.

8. Review and Continuous Improvement

The IS 17893 Work Permit System encourages a culture of continuous improvement. Organizations are expected to regularly review their safety procedures, especially after incidents or near-miss events. By learning from past experiences and adjusting safety protocols accordingly, organizations can enhance workplace safety over time.

In summary, the IS 17893 Work Permit System comprises a multi-faceted approach to workplace safety. Its key components, including permit types, risk assessment, training, emergency response, permit control, monitoring, documentation, and continuous improvement, work in tandem to create a safer work environment. By adhering to these components, organizations can mitigate risks, reduce accidents, and promote a culture of safety among their employees.

Implementing IS 17893: Best Practices

Employee Involvement

Companies that excel in implementing the IS 17893 Work Permit System actively involve their employees in safety initiatives. This creates a culture of safety where everyone is responsible for their well-being and that of their colleagues.

Regular Audits and Inspections

Regular audits and inspections are essential to ensure ongoing compliance with the code of practice. This proactive approach helps identify areas for improvement and corrective actions.

Documentation

Proper documentation of permits, risk assessments, and safety training is a fundamental aspect of IS 17893. It provides a trail of accountability and compliance.

Benefits of IS 17893 Work Permit System

Enhanced Safety

The primary benefit of the IS 17893 Work Permit System is the enhanced safety of workers. By identifying and mitigating risks, it significantly reduces the likelihood of accidents and injuries.

Regulatory Compliance

Compliance with IS 17893 is often a legal requirement in many industries. Adhering to the system ensures that companies stay on the right side of the law and avoid potential fines and penalties.

Improved Efficiency

Efficiency in the workplace is another advantage of IS 17893. With well-defined safety procedures in place, work processes can proceed smoothly without unnecessary interruptions.

Conclusion

The IS 17893 Work Permit System for 2023 is a pivotal tool in ensuring workplace safety and regulatory compliance. Its comprehensive approach to risk assessment, training, and emergency response fosters a culture of safety that benefits both employers and employees.

Implementing the system’s best practices not only enhances safety but also contributes to improved efficiency and regulatory compliance. In an ever-changing work environment, the IS 17893 Work Permit System remains a cornerstone of safety and professionalism.

The Importance of Process Hazard Analysis in Ensuring Safety

Process Safety: The Importance of Process Safety

Industrial Safety and Health Act

Excavation Safety Basic Knowledge

FAQs

- Is compliance with IS 17893 mandatory? Yes, in many industries, compliance with IS 17893 is a legal requirement to ensure the safety of employees and the workplace.

- What industries does IS 17893 apply to? IS 17893 is applicable to a wide range of industries, including manufacturing, construction, and chemical processing, among others.

- How often should risk assessments be conducted under IS 17893? Risk assessments should be conducted regularly, especially when there are changes in work processes or the introduction of new hazards.

- Are there any penalties for non-compliance with IS 17893? Yes, non-compliance can lead to fines, legal consequences, and, most importantly, endangering the safety of workers.