Safety Standard Operating Procedures Manual

Safety is paramount in any workplace environment, and ensuring employees adhere to established protocols is crucial for preventing accidents and maintaining a secure working environment. One of the foundational documents in achieving this is the Safety Standard Operating Procedures (SOP) Manual. In this comprehensive guide, we’ll delve into the intricacies of creating, implementing, and maintaining an effective safety SOP manual tailored to your organization’s needs.

Introduction to Safety Standard Operating Procedures (SOP) Manual

Importance of SOP Manuals

Safety SOP manuals serve as a roadmap for employees, outlining standardized procedures to mitigate risks and ensure workplace safety. They provide clear guidelines on handling various tasks and emergencies, promoting consistency and reducing the likelihood of accidents.

Purpose of Safety SOP Manuals

The primary purpose of safety SOP manuals is to safeguard employees and assets by establishing protocols for safe work practices. Additionally, they aid in regulatory compliance, streamline operations, and contribute to a culture of safety within the organization.

Key Components of a Safety SOP Manual

Overview of Contents

A well-structured safety SOP manual typically includes sections on regulatory compliance, risk assessment, emergency procedures, training guidelines, and documentation protocols.

Regulatory Compliance

Safety SOP manuals must adhere to industry-specific regulations and standards to ensure legal compliance and mitigate liability risks.

Risk Assessment and Management

Effective safety SOP manuals incorporate risk assessment methodologies to identify potential hazards and implement measures to mitigate risks.

Emergency Procedures

Clear and concise emergency procedures are essential for prompt and effective response to accidents, natural disasters, or other unforeseen events.

Training Guidelines

Comprehensive training guidelines ensure that employees understand and adhere to safety protocols, fostering a culture of safety throughout the organization.

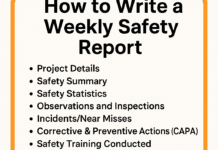

Writing a Safety SOP Manual

Research and Analysis

Developing a safety SOP manual requires thorough research and analysis to identify potential hazards, assess risks, and determine appropriate mitigation strategies.

Clear and Concise Language

Safety SOP manuals should use plain language and avoid technical jargon to ensure comprehension by all employees.

Visual Aids and Diagrams

Incorporating visual aids and diagrams can enhance understanding and retention of safety procedures, particularly for visual learners.

Review and Revision Process

Regular review and revision of the safety SOP manual are necessary to ensure it remains up-to-date and reflective of current best practices and regulatory requirements.

Implementing and Maintaining Safety SOP Manuals

Training Employees

Proper training is essential to ensure employees understand and adhere to safety SOPs. Training should be ongoing and tailored to specific job roles and tasks.

Regular Review and Updates

Safety SOP manuals should be reviewed regularly and updated as needed to reflect changes in procedures, regulations, or industry standards.

Integration with Company Culture

Integrating safety SOPs into the company culture fosters a proactive approach to safety and encourages employees to prioritize safety in their daily activities.

Tracking and Documentation

Effective tracking and documentation of safety procedures and incidents are critical for monitoring compliance, identifying areas for improvement, and demonstrating regulatory compliance.

Benefits of a Well-Designed Safety SOP Manual

Enhanced Workplace Safety

A well-designed safety SOP manual reduces the risk of accidents and injuries, creating a safer work environment for employees.

Legal Compliance

By adhering to regulatory requirements, safety SOP manuals help organizations avoid costly fines and legal liabilities associated with non-compliance.

Standardization of Procedures

Standardized procedures outlined in safety SOP manuals promote consistency and efficiency in operations, reducing the likelihood of errors and accidents.

Improved Efficiency and Productivity

Clear guidelines and procedures outlined in safety SOP manuals streamline workflows, leading to improved efficiency and productivity.

Common Mistakes to Avoid

Lack of Clarity

Complex or ambiguous language can lead to confusion and errors in executing safety procedures. Safety SOP manuals should be written in clear and concise language.

Neglecting Updates

Failing to update safety SOP manuals regularly can result in outdated procedures that do not reflect current best practices or regulatory requirements.

Failure to Train Employees

Inadequate training on safety SOPs can undermine their effectiveness. Organizations must invest in comprehensive training programs to ensure employee understanding and compliance.

Overcomplicating Procedures

Overly complex procedures can hinder employee comprehension and adherence. Safety SOP manuals should strive for simplicity without compromising effectiveness.

Conclusion

Safety SOP manuals play a vital role in promoting workplace safety, regulatory compliance, and operational efficiency. By providing clear guidelines and procedures, organizations can protect their employees and assets while fostering a culture of safety. Investing in the development, implementation, and maintenance of a well-designed safety SOP manual is essential for any organization committed to prioritizing safety.

Safety Management Plan in Coal Mines

Safety Management Plan Example

FAQs

- What is the purpose of a safety SOP manual?

- The primary purpose of a safety SOP manual is to establish standardized procedures for mitigating risks and ensuring workplace safety.

- How often should a safety SOP manual be reviewed?

- Safety SOP manuals should be reviewed regularly and updated as needed to reflect changes in procedures, regulations, or industry standards.

- Can a safety SOP manual be customized for different industries?

- Yes, safety SOP manuals can and should be customized to address the specific risks and requirements of different industries.

- Are safety SOP manuals legally required?

- While safety SOP manuals may not be legally required in all jurisdictions, they are highly recommended as a best practice for ensuring regulatory compliance and workplace safety.

- How can employees be trained effectively on safety SOPs?

- Effective training on safety SOPs involves clear communication, hands-on practice, and ongoing reinforcement to ensure understanding and compliance.