Fall Prevention in Construction: Enhancing Safety with Guardrails and Safety Nets

Introduction

Fall prevention in the construction industry is paramount to ensure the safety and well-being of workers. This article explores the crucial role of guardrails and safety nets in preventing falls from elevated surfaces, offering insights into their effectiveness, proper installation, and overall contribution to creating a safer construction environment.

Understanding the Importance of Fall Prevention

- High-Risk Environments

- Construction Sites: Elevated platforms, scaffolding, and rooftops make construction sites high-risk environments for falls.

- Severity of Injuries: Falls from heights can lead to severe injuries and fatalities, emphasizing the critical need for preventative measures.

- Regulatory Compliance

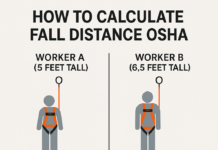

- OSHA Regulations: Occupational Safety and Health Administration (OSHA) mandates strict regulations for fall protection in construction.

- Compliance Obligations: Employers are obligated to adhere to these regulations to create a safe and compliant workplace.

Guardrails: A Crucial Line of Defense

- Primary Fall Prevention Measure

- Continuous Barriers: Guardrails act as continuous barriers along edges, providing a physical barrier against accidental falls.

- Preventing Unintentional Approaches: Guardrails deter workers from unintentionally moving close to unprotected edges.

- Key Characteristics of Effective Guardrails

- Sturdy Construction: Guardrails should be robust, capable of withstanding significant force in the event of an impact.

- Adequate Height: OSHA requires guardrails to have a height of at least 42 inches to effectively prevent falls.

- Proper Installation Guidelines

- Secure Anchoring: Guardrails must be securely anchored to the structure to ensure stability.

- Spacing Considerations: Proper spacing between vertical posts and mid-rails is essential to prevent workers from slipping through.

Safety Nets: Providing Additional Protection

- Secondary Fall Arrest System

- Below Elevated Work Areas: Safety nets are positioned beneath elevated work areas to catch workers in the event of a fall.

- Minimizing Impact Forces: Safety nets reduce the impact forces on a falling worker, lowering the risk of severe injuries.

- Effective Installation Practices

- Correct Positioning: Safety nets should be installed as close as possible under the working surface but not more than 30 feet below.

- Regular Inspections: Regular inspections ensure that safety nets are free of damage and in proper condition for effective use.

Comprehensive Fall Protection Programs

- Risk Assessment

- Site-Specific Evaluation: Conduct a thorough risk assessment to identify potential fall hazards and determine the most suitable protective measures.

- Integration of Multiple Systems: Combining guardrails, safety nets, and personal fall arrest systems creates a comprehensive fall protection strategy.

- Worker Training

- Proper Usage: Train workers on the proper usage of guardrails and safety nets, emphasizing the importance of adhering to safety protocols.

- Emergency Response: Workers should be familiar with emergency response procedures, including how to use personal fall arrest systems if needed.

Continuous Monitoring and Evaluation

- Periodic Inspections

- Structural Integrity: Regularly inspect guardrails and safety nets for signs of wear, damage, or deterioration.

- Adjustments as Needed: Make adjustments and repairs promptly to maintain the effectiveness of fall prevention measures.

- Feedback Mechanisms

- Worker Input: Encourage workers to provide feedback on the functionality of guardrails and safety nets based on their firsthand experiences.

- Continuous Improvement: Use feedback to continually improve fall prevention strategies and address emerging challenges.

Conclusion

Guardrails and safety nets play pivotal roles in preventing falls in construction, offering a dual-layered defense against the risks associated with elevated workspaces. By adhering to regulatory requirements, ensuring proper installation and usage, and integrating these measures into comprehensive fall protection programs, construction sites can significantly enhance safety standards and reduce the incidence of fall-related accidents.

Work at Height Hazards and Control Measures

OSHA Scaffold Guardrail Requirements

OSHA Stair Handrail Requirements

Frequently Asked Questions (FAQs)

- Why is fall prevention crucial in construction?

- Fall prevention is crucial in construction due to the high-risk environments created by elevated platforms, scaffolding, and rooftops. Falls from heights can lead to severe injuries and fatalities.

- What is the role of guardrails in fall prevention?

- Guardrails act as continuous barriers along edges, providing a physical deterrent against accidental falls. They are a primary fall prevention measure.

- What are the key characteristics of effective guardrails?

- Effective guardrails should be sturdy, with a height of at least 42 inches. They need secure anchoring and proper spacing between vertical posts and mid-rails.

- How do safety nets contribute to fall prevention?

- Safety nets serve as a secondary fall arrest system, positioned beneath elevated work areas to catch workers in the event of a fall, minimizing impact forces and reducing the risk of severe injuries.

- What are the components of a comprehensive fall protection program?

- A comprehensive fall protection program includes a site-specific risk assessment, worker training on proper usage and emergency response, and the integration of multiple fall prevention systems such as guardrails, safety nets, and personal fall arrest systems. Continuous monitoring and periodic inspections are also essential components.