Work at Height Hazards and Control Measures

Working at height poses significant risks to individuals involved in various industries. These hazards demand a proactive approach to ensure the safety and well-being of workers. Understanding the potential dangers, adhering to regulations, and implementing effective control measures are crucial elements in mitigating these risks.

Introduction to Work at Height

Work at height encompasses any task performed at a location where a person could fall and cause injury. It includes working on ladders, scaffolds, rooftops, and any elevated surfaces. Ensuring safety in such scenarios is imperative to prevent accidents and fatalities.

Common Hazards When Working at Height

Falls remain the most prevalent risk, accounting for a considerable number of injuries and fatalities. Additionally, the threat of falling objects and structural collapses amplifies the danger.

Understanding the Risks Involved

Statistics reveal alarming rates of accidents and fatalities related to working at height. The impact extends beyond individual workers, affecting productivity and reputation, making safety a critical concern for businesses.

Legislation and Standards

Governments and regulatory bodies have established stringent rules and standards to safeguard workers. Compliance is mandatory, and companies must adhere to these guidelines to avoid penalties and, more importantly, protect their workforce.

Identifying and Assessing Hazards

Prioritizing risk assessment allows for the identification of potential hazards. Utilizing appropriate tools and methodologies aids in preemptively addressing risks.

Control Measures for Work at Height

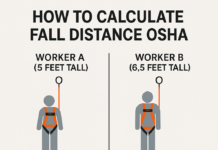

Employing suitable equipment like harnesses, guardrails, and safety nets forms a foundational aspect of mitigating risks. However, it’s not just about the tools; proper training, protocols, and adherence to safety procedures are equally vital.

Types of Protective Equipment

Various protective gear exists, tailored to different scenarios. Understanding the right equipment for specific situations significantly enhances safety.

Implementing Safety Protocols

Planning, organization, and clear communication are integral to successful safety implementations. A well-structured approach minimizes risks and ensures a safer working environment.

Role of Employers and Employees

Both employers and employees play crucial roles in maintaining safety standards. From providing adequate resources to following protocols, everyone contributes to a culture of safety.

Training and Education Programs

Continuous training and raising awareness among workers foster a safety-conscious workforce. Regular programs update knowledge and instill vigilance against potential risks.

Regular Inspection and Maintenance

Regular checks and maintenance of equipment ensure their reliability, reducing the likelihood of accidents caused by faulty gear.

Working at height poses significant risks, and implementing proper control measures is crucial to ensure safety. Some hazards include:- Falls: The most common risk, leading to severe injuries or fatalities.

- Control Measures: Use guardrails, toe boards, or safety nets. Provide fall arrest systems like harnesses and lanyards. Conduct regular inspections of equipment.

- Falling Objects: Tools, equipment, or materials dropped from height.

- Control Measures: Secure tools properly with tethers or lanyards. Use tool buckets or nets to catch falling objects. Ensure the area below is barricaded or cleared.

- Structural Stability: Unstable surfaces or structures, leading to collapse or instability.

- Control Measures: Conduct structural assessments regularly. Use appropriate access equipment like scaffolding or aerial lifts. Ensure proper training for workers.

- Lack of Training or Awareness: Inadequate knowledge of safety procedures.

- Control Measures: Provide comprehensive training on working at height hazards, equipment usage, and emergency procedures. Implement strict adherence to safety protocols.

- Weather Conditions: Wind, rain, or extreme temperatures impacting stability and visibility.

- Control Measures: Monitor weather forecasts. Halt work during adverse weather conditions. Use appropriate personal protective equipment (PPE) for weather.

- Improper Equipment Usage: Misuse or inadequate maintenance of tools and safety gear.

- Control Measures: Conduct regular inspections of equipment. Ensure proper training for equipment handling. Maintain and replace equipment as needed.

- Inadequate Rescue Plans: Lack of preparedness in case of emergencies or accidents.

- Control Measures: Develop and train teams in rescue procedures. Have emergency response plans in place and ensure all workers are familiar with them.

Following these control measures helps mitigate risks associated with working at height. It's crucial to regularly review and update safety protocols to ensure a safe working environment.Costs and Benefits of Safety Measures

Investing in safety measures might seem costly initially, but the long-term benefits outweigh the expenses, including reduced downtime and higher employee morale.

Challenges in Implementing Safety Measures

Resistance to change and practical difficulties can impede the implementation of safety protocols. Addressing these challenges requires proactive strategies and effective communication.

Conclusion

Prioritizing safety measures when working at height is non-negotiable. It’s a collective responsibility to ensure a secure environment, minimizing risks and protecting lives.

OSHA Scaffold Guardrail Requirements

OSHA Stair Handrail Requirements

OSHA Handrail and Midrail Height

FAQs

- Why is working at height so dangerous? Working at height is dangerous due to the increased risk of falls, which can lead to severe injuries or even fatalities. Factors like unstable surfaces, improper equipment usage, and human error contribute to this danger.

- What are the legal requirements for working at height? Legal requirements often include conducting risk assessments, providing proper training for workers, using appropriate safety equipment, and following specific guidelines outlined by occupational safety regulations.

- How often should safety equipment be inspected? Safety equipment should undergo regular inspections as per manufacturer guidelines and workplace safety policies. Inspections typically occur before each use and at regular intervals to ensure proper functionality.

- Are there different safety measures for specific industries? Yes, different industries may have specific safety measures tailored to their unique working environments and hazards. For instance, construction sites might have different safety protocols compared to telecommunications or window cleaning services.

- What can employees do to contribute to a safer work environment? Employees can contribute by following safety protocols, using equipment correctly, attending regular safety training, reporting hazards, and actively participating in creating a safety-conscious workplace culture.