OSHA Scaffolding Requirements

Workplace safety stands as a paramount concern for industries across the board. Among the crucial regulations and guidelines, the Occupational Safety and Health Administration (OSHA) provides comprehensive requirements for scaffolding, ensuring the protection of workers in various settings.

Importance of OSHA Regulations

OSHA regulations serve as a cornerstone for maintaining safe work environments, particularly concerning scaffolding, which plays a pivotal role in construction, maintenance, and various other industries. The stringent guidelines set by OSHA aim to prevent accidents, injuries, and fatalities associated with scaffolding use.

The Occupational Safety and Health Administration (OSHA) has specific requirements for scaffolding to ensure the safety of workers. Here are some key points:- Scaffold Design and Construction: Scaffolds must be designed by a qualified person and constructed, installed, and equipped in accordance with OSHA standards.

- Load Capacity: Scaffolds must support their own weight plus at least four times the maximum intended load without failure. They should be inspected before each work shift to ensure their stability.

- Platform Construction: Platforms must be fully planked and secured, with no gaps exceeding 1 inch between planks. They should also extend over their supports by at least 6 inches but not more than 18 inches.

- Guardrails: Guardrails, midrails, and toeboards are necessary on all open sides and ends of platforms that are more than 10 feet above the ground or floor level below.

- Access: Safe access to scaffolds must be provided and may include stair towers, ladders, ramps, or similar means.

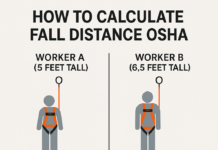

- Fall Protection: Workers must use personal fall arrest systems or guardrail systems when working on scaffolds more than 10 feet above a lower level.

- Training: Employees using scaffolds must be trained by a qualified person to recognize hazards associated with scaffolds and understand the procedures to control or minimize these hazards.

- Inspections: Scaffolds should be inspected by a competent person before each work shift and after any occurrence that could affect the scaffold’s structural integrity.

These are just some of the key requirements outlined by OSHA regarding scaffolding safety. It's essential to refer directly to OSHA's regulations (29 CFR 1926.451) and ensure compliance with all applicable standards to maintain a safe work environment.Types of Scaffolding

Supported Scaffolding

This type of scaffolding relies on rigid supports and is commonly used in construction. It offers stability and is erected from the ground upward.

Suspended Scaffolding

Suspended scaffolding hangs from the top of a building or structure. It’s commonly seen in window washing or painting activities.

Mobile Scaffolding

Portable and adaptable, mobile scaffolding provides flexibility in various job sites, allowing for easy movement and adjustment.

OSHA Standards for Scaffolding

OSHA mandates strict standards encompassing load-bearing capacities, scaffold design, and regular inspections. These standards ensure the structural integrity of scaffolds and mitigate the risk of collapses or accidents.

Training and Certification

Proper training and certification are vital for workers handling scaffolding. Ongoing education programs are necessary to keep workers updated with the latest safety protocols and procedures.

Common Violations and Risks

Instances of non-compliance with OSHA standards can lead to severe consequences, including accidents, injuries, and fatalities. Understanding and rectifying these violations are crucial to ensuring workplace safety.

Benefits of Compliance

Adhering to OSHA scaffolding requirements not only prioritizes worker safety but also helps organizations avoid penalties, fines, and legal issues arising from non-compliance.

Best Practices for Scaffolding Safety

Regular inspections, proper assembly, and the use of personal protective equipment form the core of scaffolding safety practices. These practices ensure a secure work environment.

Case Studies

Examining instances where adherence to OSHA standards resulted in enhanced safety and contrasting them with situations that lacked compliance illustrates the pivotal role of these regulations.

Challenges in Compliance

Complying with OSHA scaffolding requirements poses challenges for employers, including complexities in implementation and maintenance. Strategies must be devised to overcome these hurdles.

Future of Scaffolding Safety

Technological advancements and evolving safety standards signal a promising future for scaffolding safety, aiming to further enhance worker protection and efficiency.

Conclusion

The stringent regulations set by OSHA regarding scaffolding stand as a pillar for workplace safety, ensuring the well-being of workers across industries. Adhering to these requirements not only prioritizes safety but also avoids legal complications and fosters a culture of responsibility.

OSHA Vertical Lifeline Requirements

OSHA Fall Protection Requirements

OSHA Anchor Point Requirements

FAQs

- Why are OSHA scaffolding requirements essential?

- OSHA requirements ensure the structural integrity of scaffolds, reducing accidents.

- What are the consequences of non-compliance?

- Non-compliance can lead to accidents, injuries, fines, and legal issues.

- How often should scaffolds be inspected?

- Regular inspections are recommended before each use and after any alterations.

- Are there specific training programs for scaffold handling?

- Yes, OSHA-approved training programs exist for scaffold safety.

- What role does technology play in scaffolding safety?

- Technological advancements contribute to enhancing scaffold safety measures.