OSHA Lanyard Requirements

Workplace safety is a paramount concern for any organization. Ensuring compliance with Occupational Safety and Health Administration (OSHA) regulations, particularly regarding lanyard requirements, stands as a critical aspect of maintaining a safe work environment. Understanding and meeting these regulations not only protect employees but also mitigate potential legal and financial liabilities for businesses.

Understanding Workplace Safety Regulations

OSHA, established to enforce workplace safety standards, prescribes specific guidelines for lanyard usage in various industries. These regulations aim to prevent falls, one of the leading causes of occupational injuries and fatalities.

Specific OSHA Regulations for Lanyards

OSHA’s regulations on lanyards encompass material strength, design, and usage limitations. For instance, lanyards should have sufficient strength to sustain anticipated forces and must be selected based on the specific tasks and conditions in the workplace.

Occupational Safety and Health Administration (OSHA) has specific regulations regarding the use of lanyards in workplaces to ensure worker safety, especially in industries involving working at heights or in potentially hazardous environments.Here are some general requirements for lanyards according to OSHA:

- Material Strength: Lanyards must be made of durable materials that can support the weight they are intended to bear. They should be able to withstand certain forces without breaking or tearing.

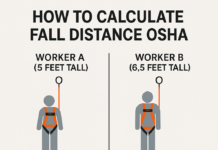

- Length: The length of a lanyard should be appropriate for the specific job and should be neither too long nor too short to prevent a fall.

- Shock Absorption: In certain situations, shock-absorbing lanyards might be required to reduce the impact force on the body in case of a fall.

- Connectors: The connectors used with lanyards (such as hooks or snaps) should be strong and properly designed to prevent accidental disengagement.

- Inspection: Regular inspection of lanyards for wear, tear, or damage is crucial. Damaged or worn-out lanyards should be replaced immediately.

- Training: Workers should be trained in the proper use, care, and limitations of lanyards. Proper usage and techniques for attaching and securing lanyards are essential.

It's important to note that specific industries or situations may have additional requirements or nuances regarding the use of lanyards. Employers should ensure they understand and comply with all relevant OSHA regulations to maintain a safe working environment.Always refer to OSHA guidelines and standards for the most accurate and up-to-date information regarding lanyard requirements in the workplace.Types of Lanyards That Meet OSHA Standards

Different types of lanyards, such as energy-absorbing, positioning, and restraint lanyards, comply with OSHA standards. The choice depends on the nature of the work and potential hazards present.

Selecting the Right Lanyard

Choosing the appropriate lanyard involves considering factors like the work environment, potential fall distances, and anchorage points. Conducting a thorough assessment helps in identifying the most suitable lanyard for the job.

Inspection and Maintenance

Regular inspection and proper maintenance of lanyards are imperative. Any signs of wear or damage should prompt immediate replacement to ensure continued safety.

Training and Education

Employee training regarding proper lanyard use is vital. It fosters a culture of safety awareness and equips individuals with the knowledge needed to utilize lanyards effectively.

Common Misconceptions About Lanyard Requirements

There are often misunderstandings surrounding OSHA regulations. Clarifying these misconceptions helps in ensuring accurate compliance with standards.

Case Studies and Examples

Real-life cases demonstrating successful compliance with lanyard regulations provide valuable insights and learning opportunities for organizations aiming to enhance safety measures.

Innovations in Lanyard Technology

Advancements in lanyard design have led to innovations that significantly enhance safety standards. Staying updated with these technological advancements aids in ensuring compliance.

The Cost of Non-Compliance

Failing to meet OSHA lanyard requirements can have severe consequences, including legal penalties and, more importantly, endangering workers’ lives.

Future Trends and Forecasts

Anticipating changes in lanyard regulations and embracing evolving safety measures ensures businesses remain proactive in maintaining a safe workplace.

Conclusion

Adhering to OSHA lanyard requirements isn’t just a legal obligation; it’s a commitment to prioritizing employee safety. By understanding, implementing, and continuously updating safety protocols, businesses demonstrate their dedication to fostering a secure working environment.

Fall Protection Plan Requirements

Work at Height Toolbox Talk Meeting

How to Make JSA for Work at Height Activity

How to Make HIRA on Work At Height?

Unique FAQs

- Are there specific industries where lanyard requirements are more stringent?Yes, certain high-risk industries such as construction, manufacturing, and telecommunications often have more stringent lanyard requirements due to the nature of their work involving heights and potential fall hazards.

- Can a single type of lanyard meet all OSHA standards for different tasks?Not necessarily. Different tasks may require specific types of lanyards based on factors like fall distances, anchorage points, and potential hazards. It’s crucial to select the appropriate lanyard for each task to meet OSHA standards effectively.

- How often should lanyards be inspected for wear and tear?Lanyards should be inspected before each use and regularly as part of routine checks. However, a thorough inspection for wear, tear, and damage should be conducted at least annually or more frequently based on usage and environmental conditions.

- What are the consequences of using non-compliant lanyards?Using non-compliant lanyards can result in severe consequences such as workplace accidents, injuries, fatalities, legal penalties, fines, and reputational damage to the organization.

- Is employee training on lanyard use mandatory according to OSHA?Yes, OSHA mandates employee training for the proper use of lanyards and other safety equipment. Training ensures that employees understand the risks associated with improper usage and fosters a culture of safety in the workplace.