OSHA Fall Protection Requirements

Introduction to OSHA Fall Protection

Fall protection stands as a crucial aspect of workplace safety, especially in industries where elevated workspaces pose risks. The Occupational Safety and Health Administration (OSHA) maintains stringent regulations to ensure worker safety, emphasizing fall protection as a key priority.

Understanding OSHA Fall Protection Requirements

Within OSHA guidelines, understanding the various fall hazards and their thresholds is essential. OSHA defines fall hazards and sets specific height requirements that trigger the need for fall protection measures. Additionally, the General Duty Clause obliges employers to provide a safe working environment, extending to fall protection.

OSHA (Occupational Safety and Health Administration) has specific regulations in place to ensure the safety of workers who are at risk of falls in the workplace.Here are some key points regarding fall protection requirements:

- General Duty Clause: OSHA requires employers to provide a workplace free from recognized hazards that may cause serious injury or death. This includes fall hazards.

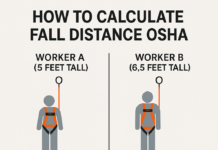

- Fall Protection Height: For general industry workplaces, fall protection is required at heights of 4 feet or more. In the construction industry, fall protection is typically required at 6 feet or higher.

- Guardrail Systems: Guardrails or barriers should be installed along open-sided walking surfaces, platforms, and other elevated work areas to prevent falls.

- Safety Nets: Safety nets can be used as a form of fall protection where workers are exposed to potential falls.

- Personal Fall Arrest Systems (PFAS): When guardrails or other forms of protection are not feasible, personal fall arrest systems, including harnesses, lanyards, and anchorage points, should be used.

- Training: Employers are responsible for training employees on how to recognize fall hazards and properly use fall protection equipment.

- Inspections and Maintenance: Regular inspections and maintenance of fall protection equipment are crucial to ensure their effectiveness and safety.

These regulations might vary depending on the industry, specific job tasks, and other factors, so it's essential for employers and workers to understand and comply with OSHA standards relevant to their work environment.OSHA Fall Protection Systems

Implementing adequate fall protection systems involves utilizing various mechanisms such as guardrail systems, safety nets, and personal fall arrest systems. Each system caters to specific workplace scenarios, ensuring comprehensive coverage against falls.

Training and Compliance

Employee training plays a pivotal role in OSHA compliance. Training programs should educate workers on identifying fall hazards, proper equipment usage, and emergency procedures, aligning with OSHA standards.

Equipment Inspection and Maintenance

Regular inspection and maintenance of fall protection equipment are vital. Employers must establish protocols for routine inspections and ensure immediate repairs or replacements to maintain equipment efficacy.

Specific Industry Requirements

Different industries, such as construction and general industries, have specific OSHA fall protection requirements tailored to their work environments. Understanding these industry-specific regulations is crucial for compliance.

Common Misconceptions about OSHA Fall Protection

Addressing misconceptions about fall protection is essential to ensure clarity and adherence to OSHA standards. This section aims to debunk common myths and clarify crucial points regarding fall protection.

Costs and Benefits of Compliance

While implementing fall protection measures incurs costs, the long-term benefits outweigh the expenses. Understanding the financial aspects of compliance can motivate employers to invest in safety measures.

Recent Updates and Changes

OSHA periodically updates its standards, impacting fall protection requirements. Staying updated with these changes is vital for maintaining compliance and ensuring worker safety.

Case Studies and Examples

Examining successful fall protection implementations through case studies offers valuable insights and lessons for organizations aiming to enhance their safety measures.

Challenges in Implementing OSHA Fall Protection

Identifying and addressing challenges in implementing fall protection measures is crucial. This section focuses on recognizing obstacles and proposing effective strategies.

International Standards and Comparison

Comparing OSHA standards with international regulations provides a broader perspective on fall protection, fostering a global understanding of safety protocols.

Technology and Innovation in Fall Protection

Advancements in technology have introduced innovative solutions for fall protection. Exploring these innovations can revolutionize workplace safety practices.

Future Trends in OSHA Fall Protection

Anticipating future trends in fall protection allows businesses to prepare for upcoming changes and advancements in safety standards, ensuring proactive compliance.

Conclusion

OSHA fall protection requirements are fundamental for ensuring workplace safety. Adhering to these regulations not only prevents accidents but also fosters a culture of safety and responsibility.

Fall Protection Plan Requirements

Work at Height Toolbox Talk Meeting

How to Make JSA for Work at Height Activity

How to Make HIRA on Work At Height?

FAQs (Frequently Asked Questions)

- What are the primary types of fall protection systems according to OSHA?

- OSHA recognizes various fall protection systems, including guardrail systems, safety nets, and personal fall arrest systems. These systems are designed to mitigate fall hazards in different work environments.

- Do OSHA fall protection requirements differ between industries?

- Yes, OSHA fall protection requirements can differ between industries. Specific regulations are tailored to suit the unique hazards present in industries like construction, general industry, maritime, and others.

- How often should fall protection equipment be inspected?

- Fall protection equipment should undergo regular inspections as per the manufacturer’s guidelines and OSHA standards. Typically, inspections should occur before each use, at regular intervals, and after any incident that could affect the equipment’s integrity.

- Are there penalties for non-compliance with OSHA fall protection standards?

- Yes, there are penalties for non-compliance with OSHA fall protection standards. Penalties can include fines, citations, and in severe cases, legal action. Ensuring compliance is crucial to avoid these consequences.

- What role does employee training play in OSHA fall protection compliance?

- Employee training is pivotal for OSHA fall protection compliance. It educates workers about identifying fall hazards, proper usage of equipment, and emergency procedures. Well-trained employees contribute significantly to maintaining a safe working environment and compliance with regulations.

If a scaffold is perfect, does require safety harness while we work at height(35 meter from the ground)?

* Work Activity is, a woker is blasting

when guardrails or other forms of protection are not feasible ,personal fall arrest system including harness,lanyards,anchorage point should be used.