OSHA Tie-Off Requirements

Introduction to OSHA Tie-Off Requirements

Safety within the workplace is a fundamental concern for employers and employees alike. The Occupational Safety and Health Administration (OSHA) sets stringent regulations to ensure a safe working environment. One crucial aspect is the enforcement of tie-off requirements to prevent falls and ensure worker safety.

Understanding OSHA Tie-Off Requirements

Tie-off requirements encompass various safety measures aimed at preventing falls from heights. These regulations dictate the use of specific fall protection systems and equipment to minimize the risks associated with working at elevated positions.

Key Elements of OSHA Tie-Off Requirements

Height Requirements

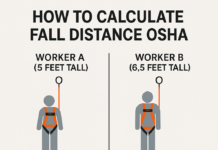

OSHA standards outline specific height thresholds that trigger the need for fall protection. Understanding these height specifications is vital for compliance and worker safety.

Anchorage Points and Connections

Properly secured anchorage points and secure connections are pivotal in ensuring the effectiveness of fall protection systems. OSHA specifies guidelines for their selection and usage.

Harness and Lanyard Specifications

The type and quality of harnesses and lanyards used play a critical role in safeguarding workers. OSHA provides detailed guidelines to ensure their adequacy and functionality.

Occupational Safety and Health Administration (OSHA) has specific requirements for tying off when working at heights to prevent falls. When working at heights of 6 feet or more in general industry, or 4 feet or more in construction, employees must be protected from falls by using guardrails, safety nets, or personal fall arrest systems (PFAS).For PFAS, they typically require a full-body harness connected to an anchor point via a lanyard or lifeline. The anchor point should be strong enough to support the worker in case of a fall. Additionally, the equipment should be inspected regularly for any signs of damage or wear.It's important to consult OSHA regulations specific to your industry and situation, as they may have additional or modified requirements depending on the circumstances of the work being performed.Common Misconceptions and Challenges

Despite OSHA’s clear guidelines, misconceptions persist regarding tie-off requirements. Addressing these misunderstandings and overcoming common compliance challenges is crucial.

Training and Education on Tie-Off Procedures

Proper training is imperative to ensure that workers understand and adhere to tie-off requirements. Employers must invest in comprehensive educational resources for their employees.

Industry-Specific Tie-Off Guidelines

Different industries have specific tie-off guidelines tailored to their working conditions. Understanding these industry-specific requirements is essential for compliance.

Ensuring Compliance and Best Practices

Regular inspections, maintenance, and the implementation of best practices are vital to maintaining compliance with OSHA tie-off requirements.

Consequences of Non-Compliance with OSHA

Failure to comply with OSHA regulations can lead to severe consequences, including penalties and compromised workplace safety and reputation.

Technological Advancements in Fall Protection

Innovative technologies are continuously being introduced to enhance fall protection measures, integrating cutting-edge solutions with traditional safety practices.

Case Studies and Real-Life Examples

Examining successful implementations and learning from past incidents can provide valuable insights into the importance of adhering to tie-off requirements.

Future Trends and Evolving Regulations

Anticipated changes in tie-off requirements and ongoing developments in safety regulations signal the need for continuous adaptation and adherence to evolving standards.

Conclusion

Adhering to OSHA tie-off requirements is not just a regulatory obligation but a commitment to prioritizing worker safety. Understanding, implementing, and continuously improving these measures ensure a safer working environment for all.

Fall Protection Plan Requirements

Work at Height Toolbox Talk Meeting

How to Make JSA for Work at Height Activity

How to Make HIRA on Work At Height?

FAQs About OSHA Tie-Off Requirements

- What are the basic OSHA tie-off requirements? OSHA’s basic tie-off requirements involve ensuring fall protection measures for workers who are at or above specific heights. This includes using proper equipment like harnesses, lanyards, and anchorage points to prevent falls.

- Are there specific guidelines for different industries regarding tie-off requirements? Yes, different industries have tailored tie-off guidelines based on their unique working conditions. Construction, for instance, might have different requirements compared to industries like manufacturing or telecommunications.

- What are the consequences of non-compliance with OSHA tie-off regulations? Non-compliance with OSHA regulations regarding tie-off requirements can result in severe penalties, fines, and even legal actions. More importantly, it puts workers’ safety at risk.

- How can employers ensure proper training for workers regarding tie-off procedures? Employers can ensure proper training by conducting regular safety sessions, providing comprehensive educational resources, and offering hands-on training with the equipment.

- What technological advancements are shaping the future of fall protection in line with OSHA regulations? Advancements like smart harnesses, drone technology for inspections, and enhanced anchorage systems are revolutionizing fall protection, aligning with OSHA’s evolving standards.

You may wish to review this post for content accuracy. Fall protection is required at 4′ in General Industry, and 6′ in Construction.

Happy New Year.

Brandon Burnette