OSHA Anchor Point Requirements: Safeguarding Workplace Safety

Workplace safety is a paramount concern for any organization, and the Occupational Safety and Health Administration (OSHA) sets stringent guidelines to ensure the well-being of workers. Among the critical safety measures enforced by OSHA are anchor point requirements, crucial elements in fall protection systems across various industries.

Understanding OSHA Anchor Point Standards

Anchor points serve as secure attachments for personal fall arrest systems, offering stability and support in scenarios where workers are at risk of falling. These points are defined by OSHA as locations used for the attachment of fall arrest equipment, and their proper design and implementation are vital to prevent potential accidents.

Key Components of OSHA Anchor Point Systems

OSHA mandates specific structural and material requirements for anchor points. The structural integrity and materials used play pivotal roles in ensuring these points can bear the required loads and resist forces in case of falls.

Structural Requirements

Anchors must be capable of supporting at least 5,000 pounds per worker attached or maintain a safety factor of at least two.

Material Specifications

Materials used must withstand environmental factors and be corrosion-resistant to guarantee longevity and reliability.

OSHA Anchor Point Inspection and Maintenance

Regular inspection is crucial to ensure the continued safety and reliability of anchor points. Routine checks for wear, damage, and proper installation are imperative to prevent failures during critical situations.

Training and Compliance with OSHA Regulations

Employers are obligated to provide comprehensive training to workers on the proper use of anchor points and fall protection systems. Compliance with OSHA regulations necessitates a thorough understanding of standards and procedures.

OSHA (Occupational Safety and Health Administration) has specific requirements for anchor points used in fall protection systems to ensure worker safety. Here are some key points:- Strength: Anchor points must be capable of supporting at least 5,000 pounds per attached worker, or meet OSHA’s criteria for a safety factor.

- Certification and Testing: Anchor points should be certified and tested by a qualified person to ensure they meet OSHA standards. This often involves engineering analysis or testing to confirm their strength and reliability.

- Compatibility: The anchor point must be compatible with the fall arrest system being used and should not cause any hazards or create additional risks.

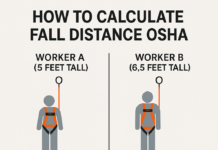

- Location: Anchor points should be positioned and installed in a way that minimizes the free fall distance and prevents swinging or striking a lower level in case of a fall.

- Inspection and Maintenance: Regular inspections of anchor points are crucial to ensure they remain in good condition. Any damage or wear should prompt immediate replacement or repair.

- Training: Workers should be trained in the proper use of anchor points and fall protection systems to maximize safety.

Always consult OSHA regulations and guidelines specific to your industry or workplace, as requirements may vary depending on the nature of work and the environment.Common Mistakes and How to Avoid Them

Instances of improper installation and misconceptions regarding compliance often lead to hazardous situations. Recognizing these mistakes is crucial to prevent accidents and ensure workplace safety.

Importance of Proper Fall Protection Systems

Anchor points are integral components of fall protection systems, significantly impacting workplace safety. Their proper utilization can prevent injuries and save lives.

Innovations in Anchor Point Technology

Advancements in anchor point technology continue to enhance safety measures, offering improved systems for worker protection. Future trends indicate further developments in this crucial safety aspect.

Case Studies Highlighting Compliance and Safety

Real-world examples showcase the importance of adherence to OSHA standards. Successful implementations highlight the positive impact on workplace safety, while non-compliance cases underscore the risks involved.

Challenges and Solutions in Implementing Anchor Point Systems

Implementing anchor point systems poses challenges across industries. Identifying and addressing these challenges is essential for effective implementation and adherence to safety standards.

The Role of Professionals in Ensuring OSHA Compliance

Seeking expert guidance from safety professionals is instrumental in understanding and implementing anchor point systems, ensuring compliance and safety in the workplace.

Understanding OSHA Anchor Point Requirements in Different Industries

Various industries have specific needs concerning anchor point requirements. Tailoring systems to suit these industries is crucial for effective safety measures.

Continuous Improvement in Anchor Point Safety

Adapting to evolving standards and practices is vital for continuous improvement in anchor point safety, ensuring that safety measures remain effective and up-to-date.

Conclusion

OSHA anchor point requirements are fundamental to ensuring workplace safety, preventing falls, and mitigating risks for workers. Adhering to these standards not only protects employees but also fosters a culture of safety within organizations, promoting productivity and well-being.

Fall Protection Plan Requirements

Work at Height Toolbox Talk Meeting

How to Make JSA for Work at Height Activity

How to Make HIRA on Work At Height?

FAQs (Frequently Asked Questions)

- What are the consequences of non-compliance with OSHA anchor point standards?

- Non-compliance can result in fines, penalties, and, more importantly, increased risks of workplace accidents leading to injuries or fatalities.

- Are there specific industries where anchor point requirements differ significantly?

- Yes, industries like construction, manufacturing, and maintenance may have varying anchor point requirements based on the nature of work and associated risks.

- Can anchor points be retrofitted into existing structures?

- In most cases, yes. However, it’s essential to ensure proper installation and compliance with OSHA standards during retrofitting.

- How often should anchor points be inspected?

- Regular inspections, at least annually or as recommended by OSHA guidelines, are crucial to ensure their integrity and reliability.

- Do anchor points eliminate fall hazards entirely?

- While anchor points are crucial in fall protection systems, other safety measures, such as guardrails and personal protective equipment, also play significant roles in mitigating fall hazards.