OSHA Guardrail Requirements: Ensuring Workplace Safety

In today’s dynamic work environments, ensuring employee safety stands as a paramount priority for every organization. The Occupational Safety and Health Administration (OSHA) plays a pivotal role in establishing and enforcing guidelines to safeguard workers across various industries. Among its numerous regulations, OSHA’s guardrail requirements hold significant importance, outlining crucial measures for workplace safety.

Introduction to OSHA Guardrail Requirements

Safety regulations serve as the backbone of a secure work environment, aiming to prevent accidents and protect employees from potential hazards. OSHA, as the governing body in this regard, sets forth comprehensive guidelines to establish safety standards within workplaces.

Understanding Guardrail Standards

Guardrails, fundamental components of workplace safety, act as barriers to prevent falls and ensure a secure working environment. OSHA delineates specific criteria and standards that guardrails must meet to guarantee optimum effectiveness.

Height Requirements for Guardrails

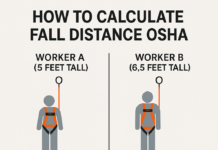

OSHA mandates specific height specifications for guardrails to ensure their efficacy. Understanding the minimum height and any exceptions or variations is crucial for compliance.

OSHA (Occupational Safety and Health Administration) has specific requirements for guardrails to ensure workplace safety. Here are some key points:- Height: Guardrails must be at least 42 inches tall from the upper surface of the top rail to the floor, platform, runway, or ramp level.

- Strength: Guardrails should be able to withstand a force of at least 200 pounds applied within 2 inches of the top edge, in an outward or downward direction.

- Top Rail: Guardrails must have a top rail that is smooth-surfaced and between 39 and 45 inches above the walking or working surface.

- Midrail: If there is no wall or parapet at least 21 inches high, a midrail or equivalent intermediate member is required between the top rail and the walking or working surface.

- Openings: Any openings in guardrails (such as between rails, posts, or other structural members) must be small enough to prevent the passage of a sphere 4 inches in diameter or larger.

- Construction: Guardrails should be constructed of materials strong enough to meet OSHA requirements and should be securely attached to the supporting structure.

- Visual Warning: Where there is a hazard of employees walking into the guardrail, a visual warning such as a high-visibility marking or color should be used.

Please note that these are general guidelines, and specific industry standards or unique workplace conditions might require additional or different measures. It's important to refer to the official OSHA guidelines or consult with a safety professional for specific compliance details in your workplace.Guardrail Materials and Construction

The materials used for constructing guardrails must meet OSHA’s approved standards to ensure durability and reliability. Proper installation and structural considerations are imperative for compliance.

Maintenance and Inspection Protocols

Regular maintenance and inspection protocols are vital to ensuring the ongoing integrity of guardrails. Addressing wear and tear promptly is essential to maintain workplace safety standards.

Training and Compliance

Employee training is a cornerstone in compliance with OSHA guardrail requirements. Ensuring workforce education and adherence to regulations are critical aspects of maintaining safety protocols.

Common Compliance Issues

Understanding typical pitfalls in meeting guardrail requirements helps in proactively addressing compliance issues. Non-compliance consequences underscore the significance of adherence.

Innovations in Guardrail Technology

Advancements in guardrail technology continuously improve safety measures in workplaces. Exploring these innovations and future trends showcases the evolving landscape of workplace safety.

Case Studies Highlighting Success Stories

Real-world instances demonstrating effective implementation of guardrail requirements serve as inspirations and examples for organizations aiming to prioritize safety.

The Financial Impact of Compliance

Conforming to guardrail regulations not only ensures safety but also has a tangible financial impact. Conducting a cost-benefit analysis emphasizes the value of adherence and avoidance of penalties.

Conclusion: Prioritizing Safety Through Compliance

In conclusion, OSHA guardrail requirements serve as a fundamental framework for ensuring workplace safety. Prioritizing compliance not only protects employees but also enhances operational efficiency and financial stability.

OSHA Vertical Lifeline Requirements

OSHA Fall Protection Requirements

OSHA Anchor Point Requirements

FAQs on OSHA Guardrail Requirements

- Do guardrails have specific height requirements according to OSHA? Yes, OSHA mandates specific height requirements for guardrails. Generally, the minimum height for guardrails is 42 inches, plus or minus 3 inches. However, there might be variations or exceptions based on specific situations or industries.

- What materials are approved by OSHA for guardrail construction? OSHA approves various materials for guardrail construction, including wood, steel, and composite materials. The key is ensuring that the materials meet the specified strength and durability standards outlined by OSHA.

- How often should guardrails be inspected for maintenance? Regular inspections are crucial for maintaining the integrity of guardrails. OSHA recommends periodic inspections, ideally at least once a month, to check for any signs of damage, wear, or any needed repairs. Additionally, after any significant event or change, inspections should be conducted.

- Are there consequences for non-compliance with OSHA guardrail standards? Yes, there can be serious consequences for non-compliance with OSHA guardrail standards. These consequences may include penalties, fines, and, most importantly, increased risk to the safety of workers.

- How do guardrail requirements contribute to overall workplace safety? Guardrail requirements are essential for preventing falls and creating a safer work environment. They act as physical barriers, minimizing the risk of accidents and injuries, ultimately promoting workplace safety.