OSHA Handrail and Midrail Height: Ensuring Safety and Compliance

Safety within workplaces and public areas is paramount, and adhering to established standards is crucial in preventing accidents and ensuring the well-being of individuals. In the realm of safety regulations, OSHA (Occupational Safety and Health Administration) provides comprehensive guidelines for various aspects, including handrail and midrail heights. These specifications are fundamental in maintaining a secure environment, but understanding and meeting these standards can be complex.

Introduction to OSHA Handrail and Midrail Height

OSHA, a regulatory body, sets specific requirements for handrail and midrail heights to safeguard individuals in diverse settings. These regulations encompass a variety of structures and environments, aiming to minimize risks associated with falls and accidents. Understanding these stipulations is vital for businesses and organizations to maintain compliance and protect their workforce and the public.

Understanding OSHA Handrail Height Requirements

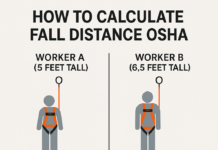

Handrail height requirements are precise measurements dictated by OSHA. These standards vary depending on the structure, ensuring adequate support and protection for individuals using stairways, walkways, or elevated platforms. Factors such as usage type and occupancy govern these specifications, emphasizing the need for tailored compliance.

In accordance with OSHA (Occupational Safety and Health Administration) standards, the height requirements for handrails and midrails on stairways and platforms should generally be around 42 inches (107 cm) for handrails and approximately 21 inches (53 cm) for midrails. These measurements are crucial for ensuring proper safety and fall protection in workplaces.Exploring OSHA Midrail Height Guidelines

Midrails play a pivotal role in enhancing safety alongside handrails. Their specific height and placement are defined by OSHA to prevent individuals from slipping or falling through open spaces. Understanding the purpose and compliance measures associated with midrails is crucial for comprehensive safety implementation.

Factors Influencing Handrail and Midrail Heights

The determination of handrail and midrail heights is not arbitrary; it considers structural elements, occupancy types, and usage patterns. These factors significantly impact the prescribed measurements, necessitating a thorough understanding of the environment to ensure compliance.

Benefits of Adhering to OSHA Standards

Adhering to OSHA regulations regarding handrail and midrail heights offers multifaceted advantages. Apart from ensuring safety, compliance mitigates legal liabilities and fosters a culture of safety within organizations, benefiting both employees and patrons.

Common Errors and Challenges in Meeting OSHA Standards

Misconceptions and practical challenges often impede compliance with OSHA standards. Addressing these issues, including erroneous beliefs about height requirements and practical difficulties faced by industries, is crucial in fostering better adherence to safety measures.

Steps to Ensure Compliance with OSHA Handrail and Midrail Heights

Maintaining compliance involves consistent inspection, maintenance, and employee training. Establishing robust protocols and ensuring regular checks are essential components of a comprehensive safety strategy.

Case Studies Highlighting Compliance Success

Numerous industries have successfully implemented OSHA standards, yielding positive outcomes in terms of safety and productivity. These cases underscore the practical benefits of stringent adherence to safety measures.

Future Trends and Developments in Handrail and Midrail Heights

The landscape of safety measures is dynamic, with ongoing innovations and potential revisions to existing standards. Staying abreast of these developments is essential for businesses and organizations aiming to maintain optimal safety standards.

Conclusion

OSHA’s guidelines on handrail and midrail heights serve as pillars of safety across various settings. Compliance with these standards not only ensures legal adherence but also fosters a culture of safety, safeguarding individuals and enhancing operational efficiency.

OSHA Vertical Lifeline Requirements

OSHA Fall Protection Requirements

OSHA Anchor Point Requirements

FAQs (Frequently Asked Questions)

- What is the minimum handrail height according to OSHA standards?The minimum handrail height, according to OSHA standards, is 42 inches. This measurement provides proper support and protection for individuals using stairways, walkways, or elevated platforms.

- Do OSHA regulations differ for different types of structures?Yes, OSHA regulations may vary based on the type of structure. Different environments and structures might have specific requirements based on their usage, occupancy, and structural design.

- Why are midrails crucial in safety compliance?Midrails are crucial as they prevent individuals from slipping or falling through open spaces on elevated platforms or staircases. They serve as an additional safety measure to ensure comprehensive protection.

- How often should inspections for handrail and midrail heights be conducted?Inspections for handrail and midrail heights should be conducted regularly as part of a comprehensive safety protocol. The frequency of inspections may vary based on usage, environmental conditions, and regulations but should be carried out routinely.

- Are there penalties for non-compliance with OSHA height regulations?Yes, non-compliance with OSHA height regulations can result in penalties. These penalties can vary in severity and may include fines or legal actions, highlighting the importance of adhering to safety standards to avoid such consequences.